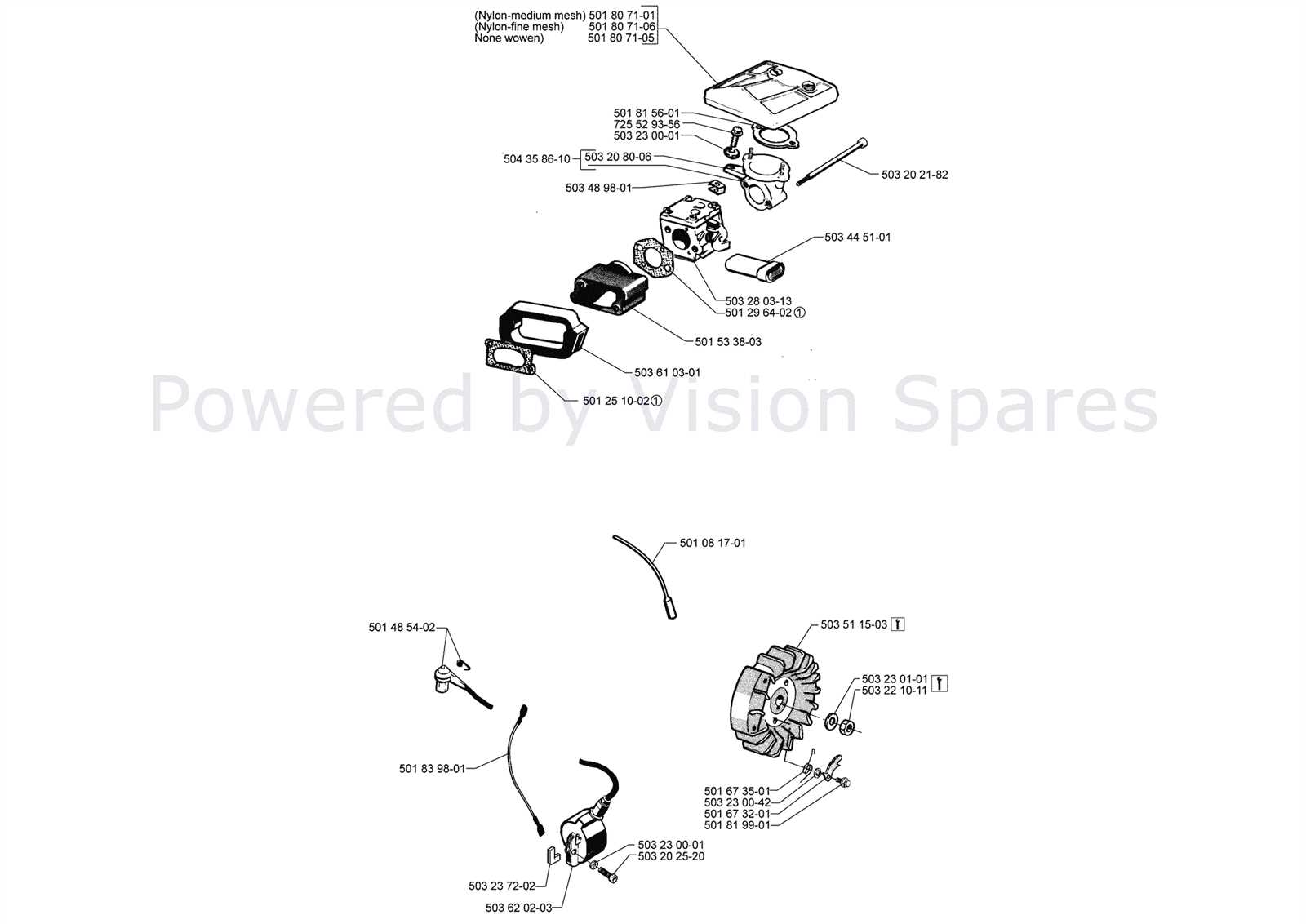

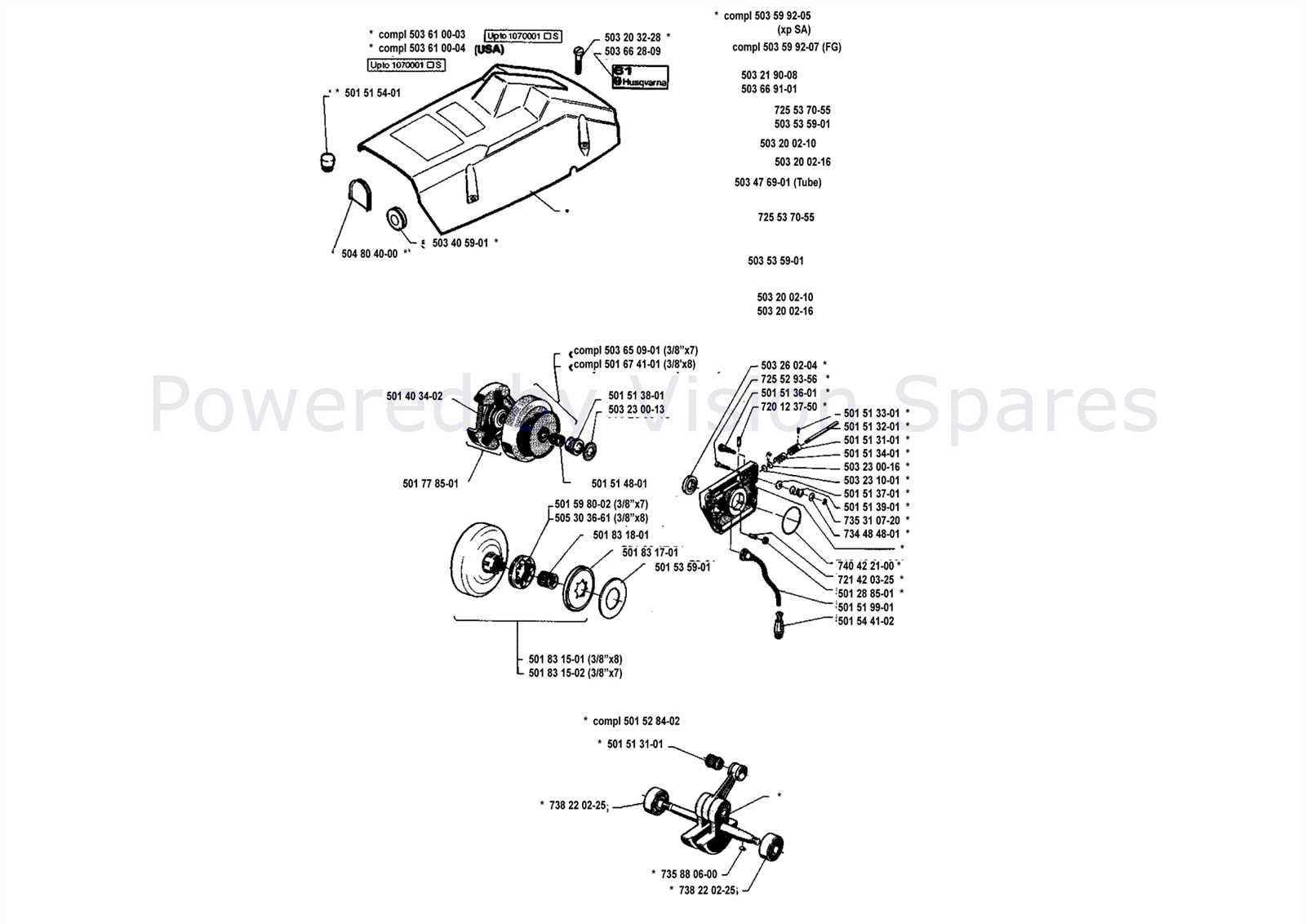

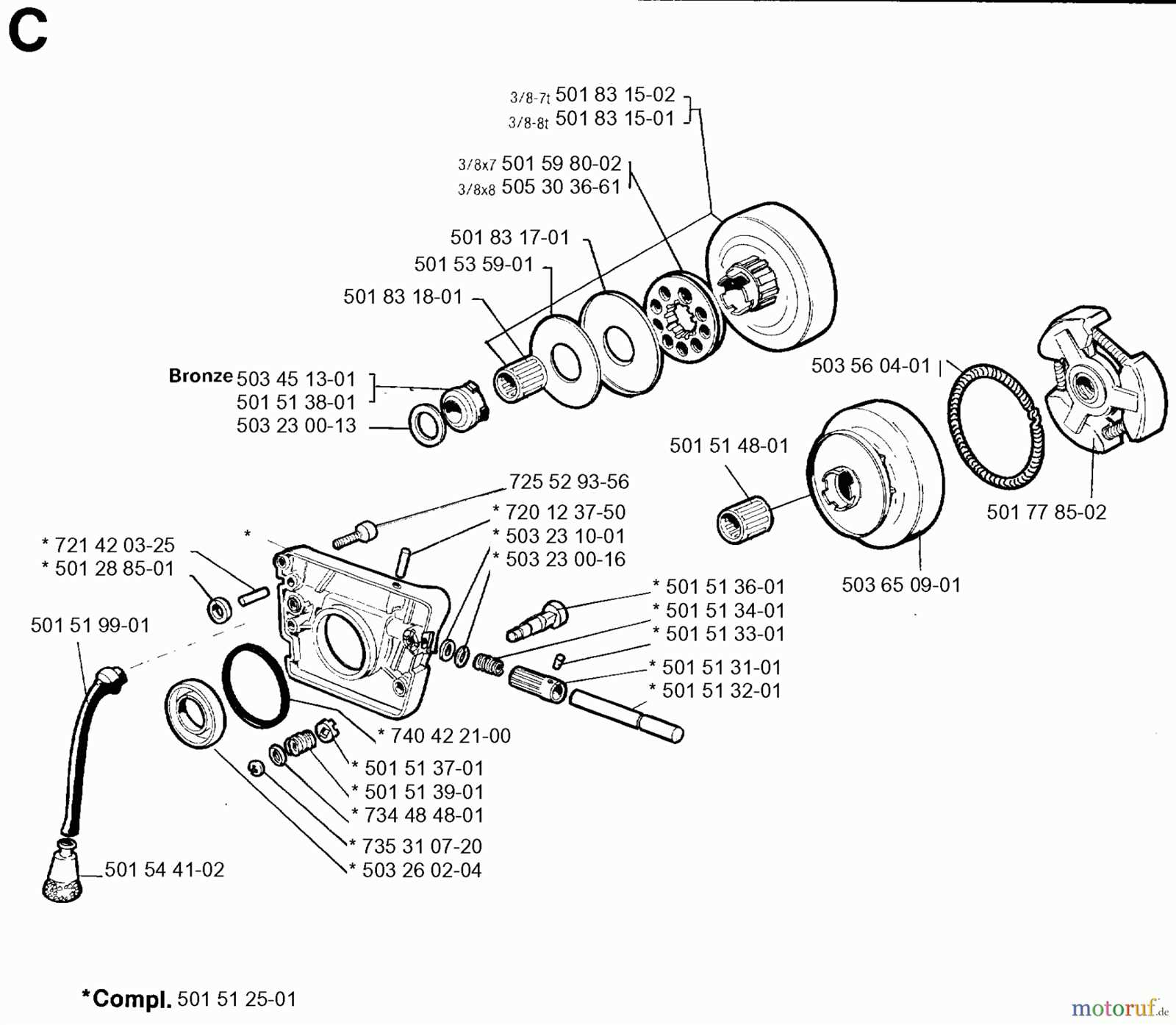

Properly maintaining your chainsaw is essential for its longevity and performance. Knowing the individual components and their functions will help you troubleshoot, replace, and repair parts efficiently. A clear understanding of how each piece fits into the system ensures smoother operation and minimizes the risk of malfunction.

With a detailed visual guide, you can easily locate and identify any worn or damaged components. This makes it easier to keep your tool in optimal condition, preventing costly repairs in the future. Being familiar with the layout of the chainsaw will save you time and effort during routine maintenance tasks.

Whether you’re a seasoned professional or a beginner, having a reference to the assembly structure of your tool is invaluable. By recognizing the various parts and their relationships, you’ll gain confidence in maintaining and fixing your chainsaw independently.

Understanding the Husqvarna 61 Components

For optimal performance, it is essential to become familiar with the key components of your chainsaw. Each individual piece plays a specific role in the machine’s functionality, contributing to smooth operation. Understanding how the components interact will help you maintain, repair, or replace them with ease, ensuring your equipment remains in good working condition.

Key Components of the Chainsaw

The chainsaw consists of several critical elements that work together seamlessly. The engine provides power, while the clutch engages the drive system to move the chain. Additionally, the air filter and carburetor ensure proper fuel combustion, while the bar and chain assembly are responsible for cutting. Understanding the role of each component helps you address specific issues when they arise.

Identifying and Replacing Worn Components

Over time, certain components may experience wear and tear. Identifying these parts early on can prevent larger issues from developing. Regular inspection allows you to spot damaged or worn-out pieces, such as the chain, guide bar, or spark plug. Once identified, replacing these components ensures your chainsaw continues to perform efficiently and safely.

Identifying Key Parts for Maintenance

Regular maintenance is crucial to extend the lifespan of your chainsaw and ensure it operates at peak efficiency. Identifying the essential components that require attention is the first step in keeping the tool in good condition. This allows you to focus on parts that have a significant impact on performance, helping you address issues before they become major problems.

Essential Components to Inspect

The engine, guide bar, chain, and air filter are among the most important elements that need regular checking. The engine should be inspected for proper fuel and spark plug function, while the guide bar and chain should be assessed for wear or damage that could affect cutting performance. Additionally, keeping the air filter clean and free of debris ensures optimal engine performance.

Signs of Wear and Damage

Recognizing signs of wear and tear is key to effective maintenance. For example, a dull or damaged chain can reduce cutting efficiency, while a clogged air filter can strain the engine. Regularly inspecting these components allows you to replace them promptly, avoiding unnecessary downtime and keeping your chainsaw in top shape.

How to Use the Husqvarna 61 Diagram

A visual reference of your chainsaw’s components can be an invaluable tool when it comes to repairs or maintenance. Knowing how to use such a guide efficiently allows you to quickly locate the specific parts that need attention. By understanding the layout of each component and its function, you can troubleshoot issues more effectively and make necessary replacements without confusion.

Here’s how to use the visual guide for maintenance tasks:

- Locate the component: Start by identifying the part you want to inspect or replace. The visual reference will show you where it’s situated in relation to other elements of the chainsaw.

- Understand the connections: Pay attention to how different components are connected. This helps you understand which parts need to be removed or disconnected before you can access the one you’re working on.

- Check for wear: Once you’ve located the component, inspect it for any signs of wear or damage. The guide can help you determine if the part is in need of repair or replacement.

Using the visual guide can make the maintenance process smoother and ensure that you don’t miss any important steps. Whether you’re fixing or replacing a part, this tool provides clarity, helping you to efficiently complete the task.