When it comes to maintaining your lawn care equipment, having a clear understanding of its key components is essential. A comprehensive visual guide can help you identify each part, ensuring effective repairs and replacements. Whether you’re troubleshooting a malfunction or performing routine maintenance, knowing how to navigate through the various elements of your machine is critical for optimal performance.

In this section, we will explore a detailed breakdown of the critical components of your mower. With the right information, you can make informed decisions about repairs, replacements, and maintenance tasks. This guide will help you identify common issues and offer solutions, ensuring your equipment stays in top condition for longer use.

Understanding the Husqvarna RZ4623 Components

To ensure the longevity and smooth operation of your lawn mower, it is important to understand the core components that make up the machine. Knowing the function of each part allows you to spot issues early, perform effective maintenance, and replace worn-out elements without difficulty. Whether you’re new to mower maintenance or an experienced user, familiarizing yourself with these components is the first step toward keeping your equipment in optimal condition.

Main Operational Parts

The primary elements of a mower typically include the engine, transmission, cutting deck, and wheels. Each part plays a critical role in the performance of the machine, from driving power to enabling smooth movement and efficient grass cutting. Understanding how these pieces work together will give you a solid foundation for maintaining or troubleshooting your mower when needed.

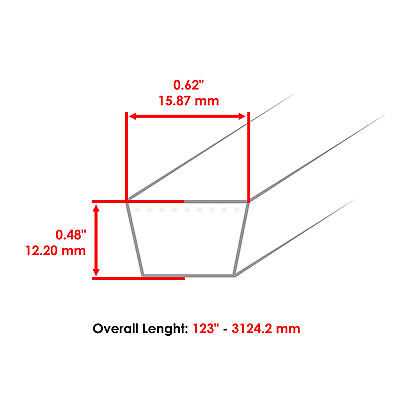

Aside from the core elements, there are various smaller components that support and enhance the mower’s performance. These include belts, pulleys, and control cables. Regularly inspecting and replacing these parts will help ensure the mower operates efficiently and prevents unexpected breakdowns. The upkeep of these smaller components often has a direct impact on the overall performance and reliability of the machine.

How to Use the Parts Diagram Effectively

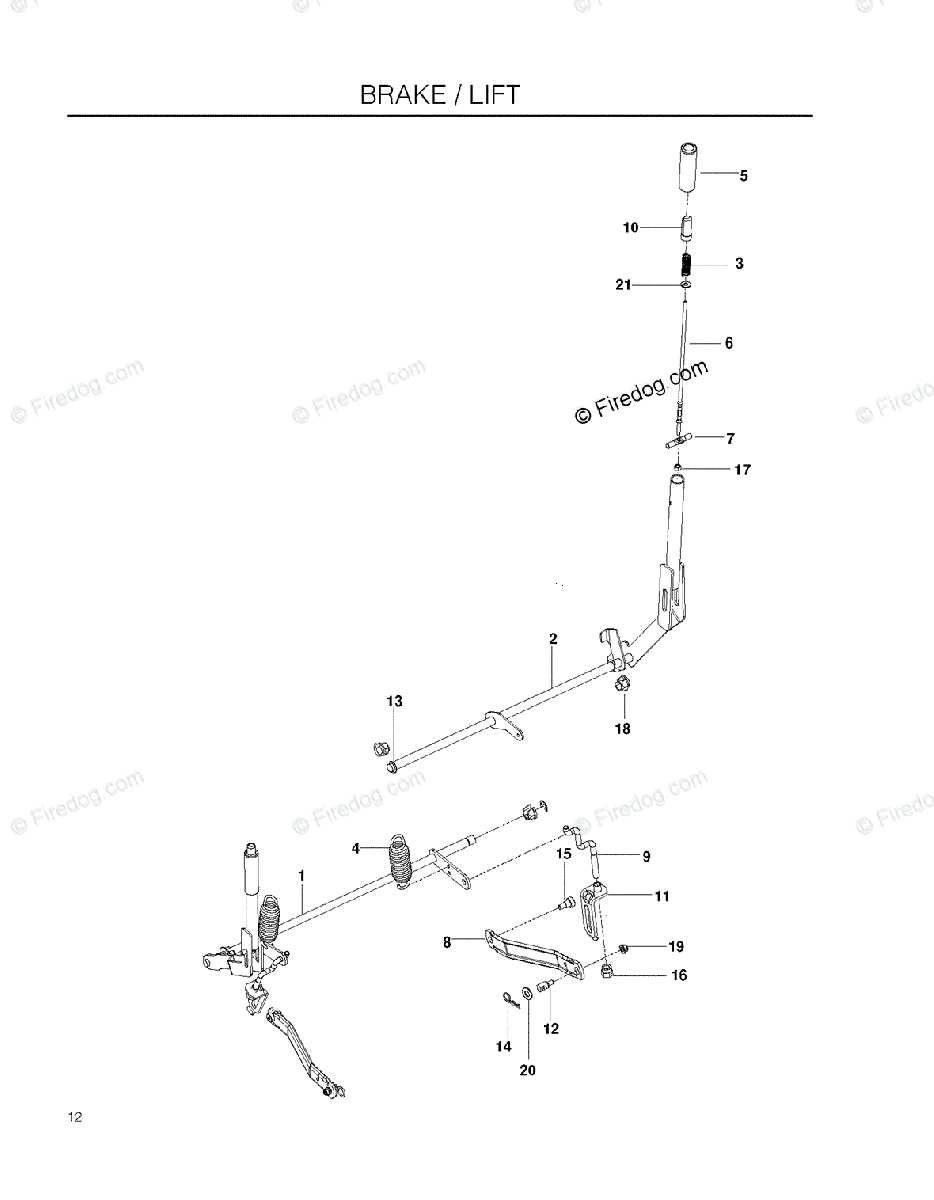

When performing repairs or routine maintenance on your lawn equipment, having a clear reference guide is essential for identifying and understanding the individual components. A visual reference allows you to pinpoint each part and its corresponding function, making the repair process much more manageable. Knowing how to read and use this guide correctly will save time and prevent unnecessary errors during maintenance tasks.

To use the reference guide effectively, start by familiarizing yourself with the overall layout and the different sections. Each component will be labeled, and these labels help to connect specific parts to their corresponding functions in the machine. Pay attention to part numbers and their locations within the system to ensure you’re working with the correct elements. If you’re unsure about the role of a part, cross-check it with the equipment manual or online resources for further clarification.

Additionally, take time to examine the diagram in relation to your current issue. Whether you’re troubleshooting a malfunction or planning preventive maintenance, a clear understanding of how each part fits together will give you greater insight into potential causes and solutions. Using this guide correctly ensures that you can perform accurate repairs, avoid mistakes, and maintain the machine in optimal condition for longer periods.

Common Issues and Solutions for RZ4623 Parts

Over time, lawn equipment can experience various issues that impact performance and efficiency. Whether it’s due to wear and tear, improper maintenance, or external factors, identifying these problems early is key to preventing costly repairs. Knowing the common issues that affect your machine’s components and how to address them can save you time and effort in the long run.

Clogged or Damaged Belts are one of the most common issues. These components are responsible for transferring power from the engine to other parts, and they can wear out or become damaged with use. To solve this, regularly inspect the belts for signs of wear or debris buildup. If damaged, replacing them with the correct replacement will restore functionality.

Engine Performance Problems can arise if fuel lines are clogged or the air filter becomes too dirty. These issues can cause the engine to stall or run inefficiently. The solution is to clean or replace the air filter and inspect the fuel system for blockages. Proper fuel maintenance and regular cleaning are essential for ensuring smooth engine performance.

Worn-Out Wheels are another frequent problem that affects movement and handling. Over time, the wheels can lose traction or develop wear that impacts maneuverability. Replacing the wheels as soon as they show signs of damage can prevent further problems and improve performance on uneven surfaces.