When working with outdoor machinery, understanding the intricate details of its structure is essential for proper maintenance and repairs. A clear understanding of each element helps users ensure their equipment operates at peak performance, minimizing downtime and improving overall efficiency.

The machinery in question consists of several key elements that work in harmony to deliver the desired results. These components, whether mechanical or electrical, contribute to the overall functionality, and each part plays a critical role. Identifying and familiarizing oneself with these parts can greatly simplify troubleshooting and upkeep.

By studying the detailed visual representation of these parts, operators can identify which areas require attention. Whether it is routine maintenance or a more complex repair, understanding the layout of each component is crucial for successful interventions. Familiarity with these details not only helps in diagnosing issues but also in making informed decisions about replacement or upgrades.

Understanding the Components of Lawn Equipment

When it comes to outdoor machinery, every piece plays an integral role in ensuring smooth operation. Understanding how each component interacts with the others helps in identifying potential issues and maintaining peak performance. A well-maintained machine will last longer and operate more efficiently, saving both time and money.

Key Mechanical Elements

The primary mechanical elements are responsible for driving the machine and performing its main tasks. These components, such as the engine, wheels, and cutting mechanisms, work together to achieve the desired result. Proper care and attention to these parts ensure the machine’s longevity and effective performance.

Electrical and Control Systems

In addition to mechanical components, the electrical and control systems are crucial for modern machines. These systems help regulate the power flow, manage the controls, and ensure the machine starts and runs correctly. Understanding how these systems interact with the mechanical parts is essential for diagnosing electrical failures or operational glitches.

Key Parts in Lawn Equipment Assembly

Every piece of outdoor machinery is made up of several essential components that function together to achieve optimal performance. Understanding these key elements helps users maintain and troubleshoot their equipment effectively. From power transmission to the cutting system, each part plays a specific role in ensuring the machine operates smoothly and efficiently.

Drive System and Power Transmission

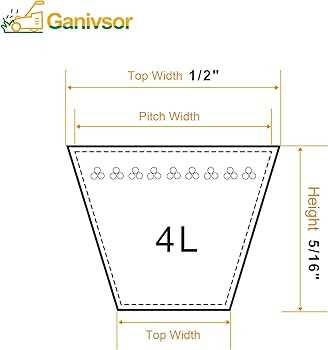

The drive system is the heart of any lawn equipment, responsible for transferring power from the engine to the wheels or cutting mechanism. This system includes gears, belts, and pulleys, all working in unison to move the machine and deliver the necessary power. Proper alignment and lubrication of these components are crucial for preventing wear and ensuring reliable performance.

Cutting Mechanism and Blade Assembly

The cutting mechanism is a central part of outdoor machinery used for lawn care. This assembly includes the blades, spindles, and motors that rotate and cut the grass efficiently. Regular inspection and sharpening of the blades ensure clean cuts and prevent strain on the machine. Understanding the structure of this system helps in identifying wear and ensuring a sharp, effective cut every time.

How to Read the Equipment Component Layout

Understanding a visual representation of machinery components is essential for effective repairs and maintenance. These detailed layouts provide a clear, organized view of each part and its connections, allowing users to identify components, their functions, and their placement within the overall assembly. Reading these illustrations properly is key to troubleshooting and performing repairs with precision.

To begin, familiarize yourself with the various symbols and labels used in these illustrations. Each component is represented by a specific shape or line, and understanding the meaning behind these elements helps in navigating the layout. Additionally, numbered sections often correspond to parts in the manual or a parts list, making it easier to identify and order replacements if necessary.

When reading these diagrams, pay close attention to how different parts are connected. This can help in understanding the flow of power or movement through the machine, and can assist in pinpointing areas that may need maintenance or repair. By following these visual cues, you can more effectively assess the condition of the machine and perform any necessary troubleshooting tasks.