When exploring the components responsible for a vehicle’s maneuverability, it’s essential to grasp how each element works together to ensure smooth and precise handling. The system responsible for guiding the wheels and maintaining stability plays a crucial role in every driving experience. Knowledge of these key mechanisms can help both enthusiasts and technicians troubleshoot, maintain, or upgrade their ride effectively.

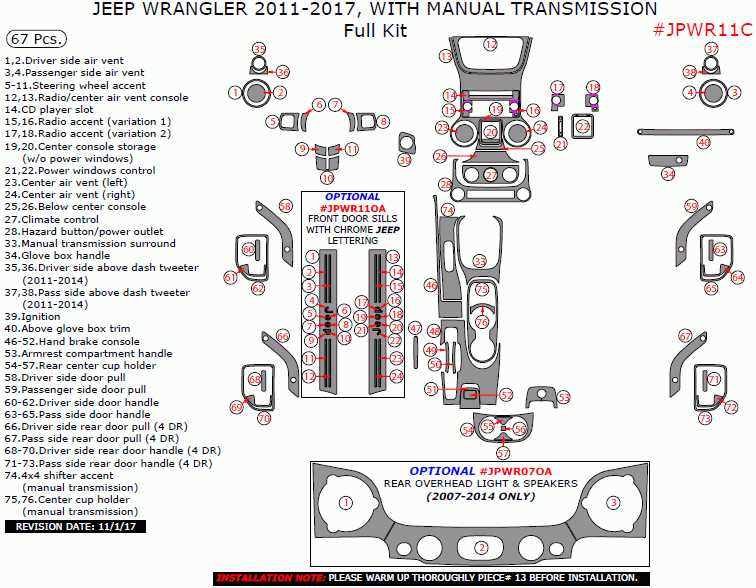

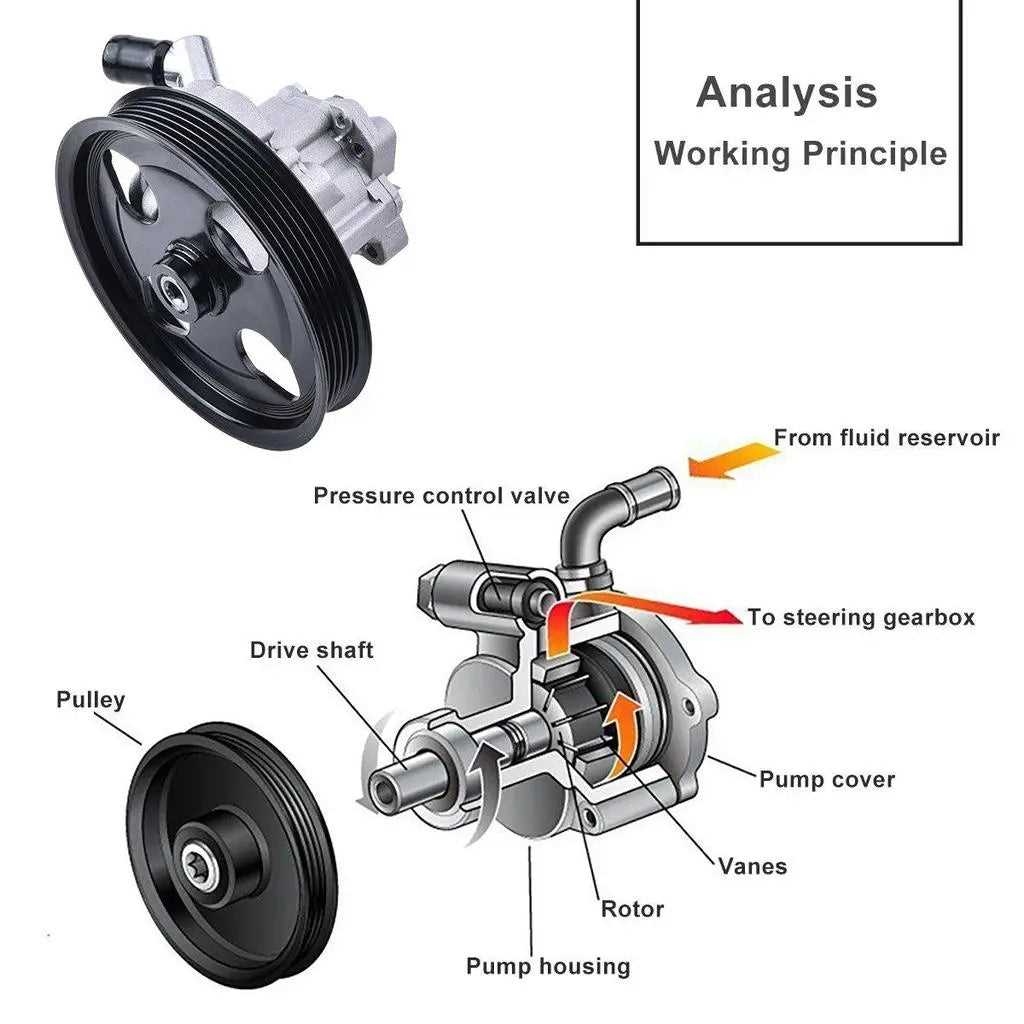

Detailed illustrations and schematics allow one to identify and understand the function of each component involved in the process. These visuals serve as a reference for anyone looking to delve deeper into vehicle maintenance, repair, or modification, providing clarity on how the intricate pieces interact with each other.

In this guide, we’ll break down the essential elements of the system, highlighting potential issues and their solutions. Whether you’re an owner aiming to enhance performance or a mechanic diagnosing problems, understanding the structure and connections will lead to more informed decisions and better outcomes.

Understanding Jeep Wrangler JK Steering System

The system that controls vehicle movement and direction is composed of multiple interconnected components. These elements work together to provide smooth and precise control while driving, ensuring both safety and comfort. The key to this mechanism lies in the proper functioning of each individual segment, from the linkages to the actuators, all contributing to the vehicle’s overall handling performance.

This setup enables the driver to change the vehicle’s orientation with minimal effort. It translates input from the operator into mechanical adjustments, allowing for swift turns and responsive navigation. The system operates through a series of well-engineered connections, each of which must remain in optimal condition to avoid driving complications.

Efficient maintenance of this configuration involves understanding how each element contributes to the system as a whole. Regular checks and timely replacements of worn components are crucial to preserve the vehicle’s handling characteristics and ensure longevity. Proper alignment and calibration of each link are essential for the system to perform at its peak.

Key Components in Steering Assembly

The assembly responsible for controlling vehicle direction consists of several vital elements, each playing a crucial role in ensuring smooth and responsive handling. These components are interconnected to form a system that translates driver input into accurate vehicle movement. Understanding how each piece works within this system is essential for proper maintenance and performance.

Linkage System

The linkage system connects the driver’s input to the wheels, facilitating turning actions. This network of rods and joints ensures that force is transmitted effectively from the control mechanism to the tires. The quality and durability of these components directly affect the precision and ease with which a vehicle responds to direction changes.

Actuators and Mechanisms

Actuators within the system control specific movements by adjusting the alignment or angle of key parts, allowing for accurate vehicle response. These mechanisms are responsible for enabling changes in the vehicle’s position, such as turning, stabilizing, or realigning. Proper functioning of the actuators ensures that the vehicle remains responsive and predictable, even under varying road conditions.

Common Issues with Jeep JK Steering

The system responsible for vehicle direction control can experience several common issues over time. These problems often arise due to wear and tear, lack of maintenance, or external factors like road conditions. Addressing these issues promptly is crucial for maintaining safe and responsive handling. In this section, we’ll explore some of the most frequent complications encountered within this system.

Loose or Worn Linkages

Worn or loose linkages can lead to a lack of precision when turning. Over time, the joints and rods that connect various elements of the system may degrade, causing play in the mechanism. This results in a delayed or imprecise response, making the vehicle feel less controlled, especially during sharp turns or at high speeds.

Misalignment of Components

Another common issue is misalignment of the system’s components. When the parts are not correctly aligned, the vehicle may pull to one side, or the control inputs might feel uneven. Misalignment can stem from several factors, including accidents or rough driving conditions, which can cause parts to shift out of place. It’s important to realign the system to restore proper functionality and avoid additional strain on other parts.