When it comes to maintaining outdoor power equipment, having a clear understanding of the engine’s internal layout is essential. A well-documented component breakdown can make repairs and replacements much easier, ensuring the machine operates smoothly for years. Knowing each part’s role and how they interconnect can save time and reduce errors during maintenance tasks.

In this guide, we will explore how to read and interpret the various visual guides that illustrate key engine elements. Whether you’re a DIY enthusiast or a professional technician, learning to navigate these resources can significantly enhance your repair and maintenance skills. From common wear items to more complex mechanisms, this knowledge helps ensure optimal performance and longevity.

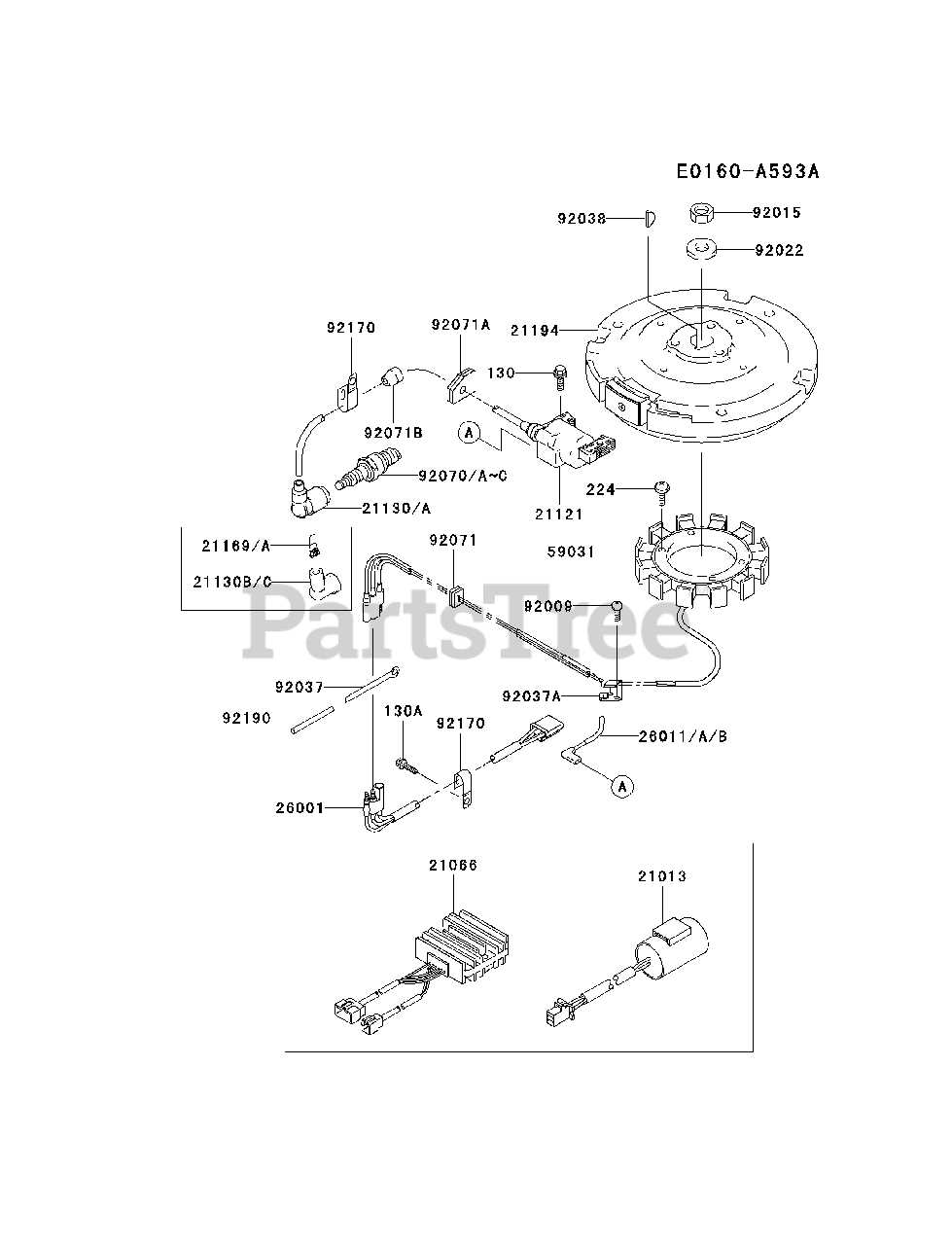

Kawasaki FC420V Engine Breakdown

Understanding the structure of an engine is crucial for efficient operation and repair. Each component plays a specific role in the overall performance, from powering the system to ensuring smooth operation. Analyzing the engine layout allows users to identify key sections and their interconnections, which is vital for diagnosing issues or performing regular maintenance.

Breaking down the engine into its core units, such as the ignition system, fuel delivery mechanisms, and exhaust components, helps reveal the essential functions of each part. This breakdown provides a clear understanding of how individual elements contribute to the engine’s overall efficiency. With this knowledge, users can effectively troubleshoot problems and maintain their equipment with confidence.

Essential Parts of Kawasaki FC420V

Every engine is made up of several critical components that work together to ensure smooth and efficient operation. These elements are fundamental to the engine’s performance, and understanding their function is key to maintaining optimal performance. From the ignition system to the fuel delivery mechanism, each part plays a vital role in keeping the engine running at its best.

The ignition system is responsible for starting the engine by generating the spark needed to ignite the fuel. The fuel pump ensures the engine receives the proper fuel supply, while the carburetor mixes the fuel and air in the correct ratio for combustion. Other vital components include the valve train, which controls the intake and exhaust valves, and the crankshaft, which converts fuel energy into mechanical movement.

Each part is designed to work seamlessly with others, contributing to the engine’s efficiency and reliability. Familiarizing yourself with these essential components will help you troubleshoot problems and perform maintenance tasks with greater ease and confidence.

How to Use the Parts Diagram

Interpreting visual guides that showcase an engine’s internal layout is essential for effective maintenance and repair. These guides provide a clear illustration of each component and its placement, allowing users to identify parts and understand their functions. By learning how to use these visual resources, one can simplify troubleshooting and part replacements.

Begin by familiarizing yourself with the general layout, noting the key sections such as the fuel system, ignition components, and exhaust mechanisms. Each element will be labeled, making it easier to locate specific items during repair. These guides often also highlight different part numbers, helping you find the correct replacements when necessary. By cross-referencing the guide with the physical engine, you can ensure accuracy and efficiency in your maintenance tasks.