For anyone working on vehicle maintenance or repairs, having a clear understanding of the internal structure is essential. A well-detailed schematic can guide you through the complexities of each section, helping you identify individual components and their connections. Knowing how to interpret such layouts is a vital skill for anyone involved in mechanical work.

By studying the organization of various parts, you can easily locate issues, perform replacements, and ensure that everything functions as intended. Understanding these visual representations enables you to streamline repairs and upgrades while minimizing the risk of errors. Additionally, it helps in selecting the correct replacement items and making informed decisions during troubleshooting.

Whether you’re a professional mechanic or a DIY enthusiast, learning how to read these diagrams is an invaluable asset. Mastering this skill will save both time and effort, leading to more efficient maintenance and fewer costly mistakes.

Understanding the Vehicle Components

To effectively maintain and repair any off-road utility vehicle, it’s crucial to familiarize yourself with its key elements and their layout. Each section of the vehicle works in harmony, and a comprehensive understanding of how everything fits together can significantly enhance troubleshooting and repair processes. Knowing the different systems and their relationships with one another helps you make informed decisions when addressing issues or replacing components.

Major Systems and Their Functions

Typically, an off-road utility vehicle is made up of various systems, each serving a specific purpose. These include the engine, transmission, electrical systems, suspension, and more. Understanding the function of each part within these systems will help you pinpoint problems quickly. For example, the drivetrain system is responsible for transmitting power from the engine to the wheels, while the suspension system plays a key role in maintaining stability and comfort on uneven terrain.

Identifying and Locating Key Elements

When working on vehicle maintenance, knowing where to locate essential components is crucial. Whether it’s the fuel system, brakes, or cooling system, each section will have distinct components that require attention. A schematic map of the vehicle’s internal layout can simplify this task, making it easier to spot worn-out or damaged parts and replace them efficiently. With practice, you’ll be able to identify and troubleshoot issues much faster, ensuring smooth operation and longevity of the vehicle.

How to Read the Layout Effectively

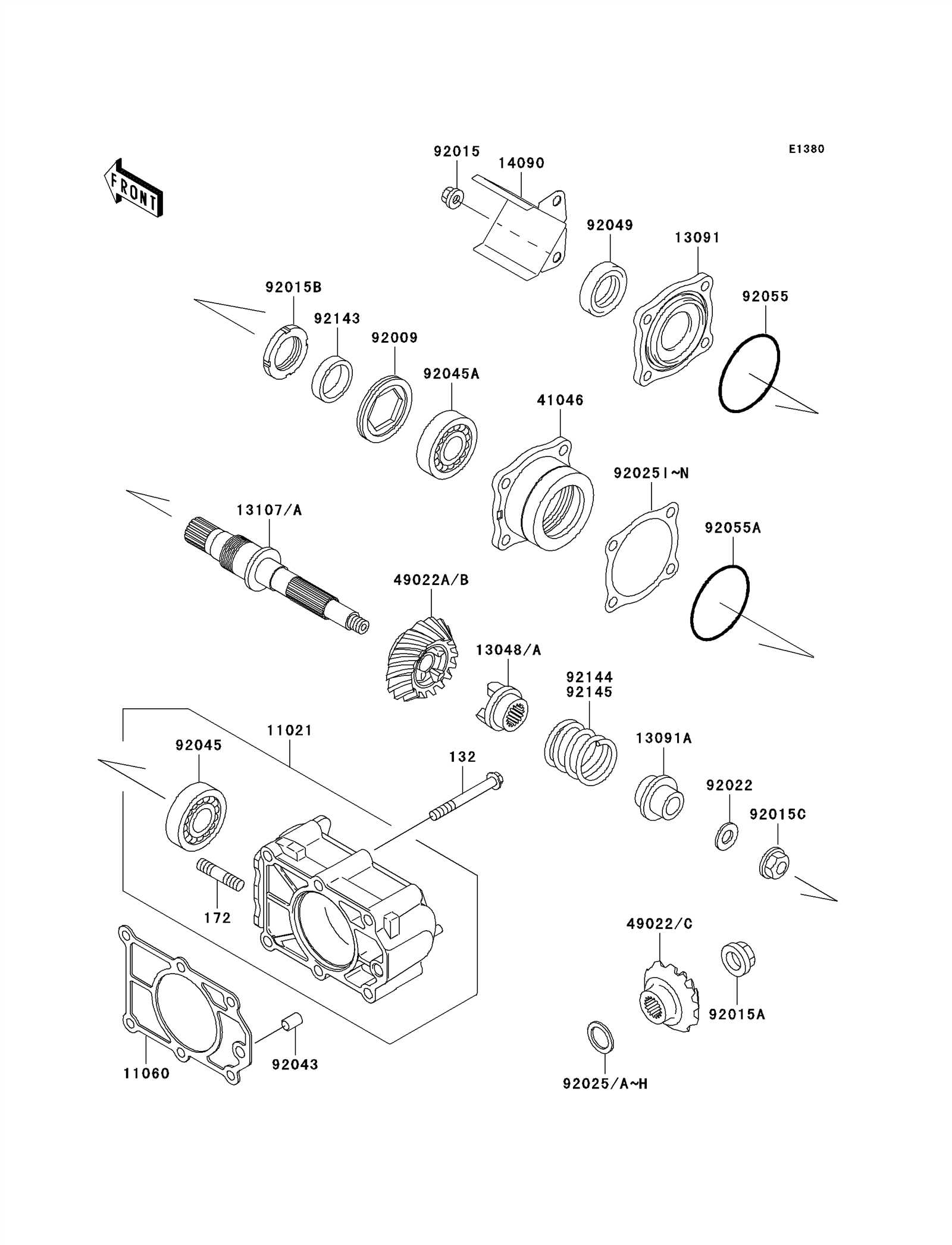

Reading a schematic for any vehicle requires an understanding of how components are organized and represented visually. These layouts serve as a guide, allowing you to identify different sections, their functions, and how each element interacts within the larger system. Mastering the skill of reading these representations can make maintenance and repairs much more efficient.

Identifying Symbols and Labels

The first step in interpreting these visuals is recognizing the symbols and labels used to represent various components. Each part of the vehicle, whether mechanical or electrical, is depicted through standard icons or shorthand text. Pay attention to these details as they provide important clues on how different elements are connected or controlled. For instance, symbols might represent different types of fasteners, connectors, or fluid lines.

Understanding Relationships Between Components

Once you familiarize yourself with the symbols, it’s essential to understand how each element interacts within the system. Lines connecting different parts indicate a relationship, such as power transmission, fluid flow, or electrical circuits. By following these connections, you can trace problems or malfunctions back to their source more quickly, ensuring efficient troubleshooting and repairs.

Common Repairs Using the Layout

Having a clear understanding of the layout can be a game-changer when it comes to repairs. With the right schematic, you can quickly locate damaged or worn-out components, allowing you to perform repairs with accuracy and efficiency. Whether it’s replacing a faulty part or performing routine maintenance, these guides provide the necessary information to get the job done properly.

One of the most common repairs involves the drivetrain, where components like the transmission or axle may require attention. By referencing the layout, you can easily pinpoint the affected area and follow the correct procedures to address the issue. Similarly, electrical problems, such as wiring faults or faulty connections, can be diagnosed and fixed faster by following the circuit diagrams, ensuring that power is restored to the system without complications.

Other frequent repairs include suspension replacements, brake system maintenance, and cooling system fixes. Each of these areas benefits from a detailed visual guide, allowing you to understand where specific parts are located and how to replace them without unnecessary disassembly. Understanding these layouts enhances your ability to perform repairs quickly and accurately, minimizing downtime and increasing vehicle longevity.