When maintaining or repairing any off-road vehicle, having a clear and detailed reference to its individual components is crucial. Knowing the exact location and function of each part can save both time and effort, ensuring smooth operations and preventing unnecessary damage. A detailed breakdown of these components allows for more precise handling and identification when working on the machine.

Comprehending the structure of a vehicle helps in recognizing the most common problems that may arise. It also assists in proper troubleshooting, simplifying the process of locating a malfunctioning component. Whether you’re a seasoned mechanic or a first-time user, understanding the layout can significantly enhance your experience.

In this guide, we’ll explore how to make the most of such references and how they aid in identifying key components, pinpointing issues, and ensuring your vehicle runs at its best. From simple repairs to more complex upgrades, a well-understood reference becomes an invaluable tool.

Understanding the Vehicle Component Layout

Every vehicle is made up of numerous parts that work together to ensure smooth operation. Recognizing and understanding these components is key to maintaining the overall functionality of the machine. A detailed layout can help identify where each element is located, what its purpose is, and how it interacts with other components.

When you gain a comprehensive understanding of a vehicle’s structure, you can more easily diagnose problems, plan repairs, and perform maintenance. This knowledge is not just for professional mechanics–it is beneficial for anyone who wants to ensure the vehicle is in top condition. The clearer the reference to each part, the faster and more efficient the process of fixing or upgrading becomes.

How Parts Work Together

All components within the vehicle interact to create seamless movement and performance. From the engine and suspension to electrical systems, each piece plays a vital role. Understanding how these elements connect and affect each other is essential for diagnosing issues and determining solutions.

Importance of Clear Component References

Having an accessible layout of all parts makes it easier to pinpoint problems without wasting time searching for specific elements. It enhances your ability to work more effectively, whether you’re replacing a damaged item or performing routine checks. A clear reference simplifies complex tasks and minimizes the risk of errors during maintenance.

How to Use the Component Layout Effectively

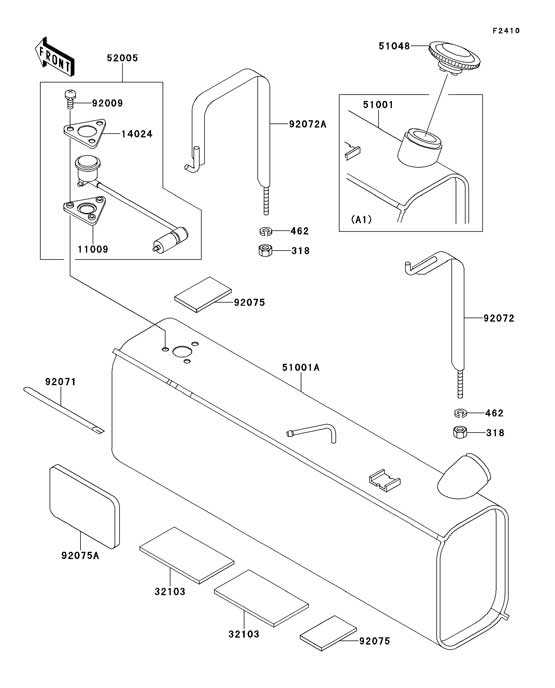

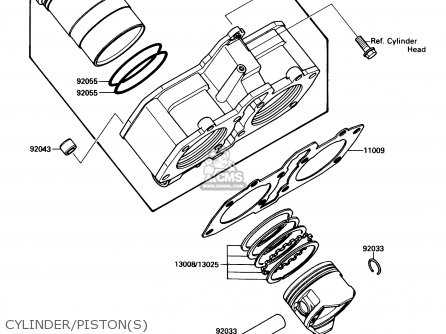

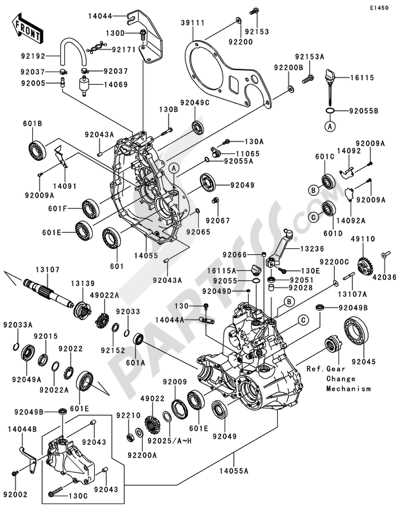

Having a clear visual reference to the individual elements of a machine is a valuable tool when performing maintenance or repairs. Understanding how to navigate this reference can significantly enhance your ability to quickly identify the parts you need, troubleshoot problems, and make informed decisions. It’s essential to approach this resource methodically to maximize its usefulness.

Begin by familiarizing yourself with the overall structure of the layout, identifying the most critical areas. Focus on the main components first, such as the engine, drivetrain, and electrical systems, and then move on to secondary elements like the suspension or body frame. By understanding the general flow of the reference, you can locate specific parts with greater ease.

Identify Key Areas and Components

Start by focusing on the most essential sections that directly impact the vehicle’s functionality. The layout typically organizes these primary components in a logical order. Knowing which section addresses a particular system or part allows you to quickly pinpoint issues and assess their severity. If something appears off, you can focus on that area without wasting time searching through unrelated sections.

Cross-Reference for Accurate Identification

To ensure you’re selecting the correct replacement or fixing the right issue, it’s often helpful to cross-reference the layout with other available resources, such as user manuals or service guides. These additional references provide further detail and context, helping you verify part numbers and other important specifications. This approach reduces the chances of errors and ensures precision when making repairs or replacements.

Common Issues and Component Identification Tips

When working on any off-road vehicle, it’s important to understand the most frequent issues that arise and how to identify the affected parts. Whether it’s a malfunctioning system or general wear and tear, recognizing the symptoms early can save time and prevent further damage. Having a solid understanding of common problems and how to pinpoint the right component is key to effective repairs.

One of the most frequent issues with off-road vehicles involves engine performance, often related to fuel delivery, ignition, or air intake systems. Recognizing irregularities in these areas can quickly lead you to the necessary parts for inspection or replacement. By understanding the vehicle’s layout, you’ll be able to find the right component with minimal effort and address the issue more efficiently.

Identifying Worn or Faulty Components

Over time, components such as belts, bearings, or filters may show signs of wear. These parts can be identified through visible damage, unusual noises, or poor performance. Understanding where these parts are located within the vehicle allows you to perform regular checks and make early repairs before a more serious breakdown occurs.

Using a Visual Reference for Accuracy

A visual reference is an invaluable tool for making sure you’re replacing the correct part. When in doubt, cross-check the location and appearance of the component with the reference to ensure accuracy. Taking the time to match the part visually can prevent unnecessary replacements and avoid the risk of using incompatible components.