Proper maintenance of your cleaning equipment requires understanding its internal structure. Whether you’re a novice or experienced user, familiarizing yourself with its key elements is essential for effective use and repairs. This knowledge can significantly extend the lifespan of your appliance and enhance its performance.

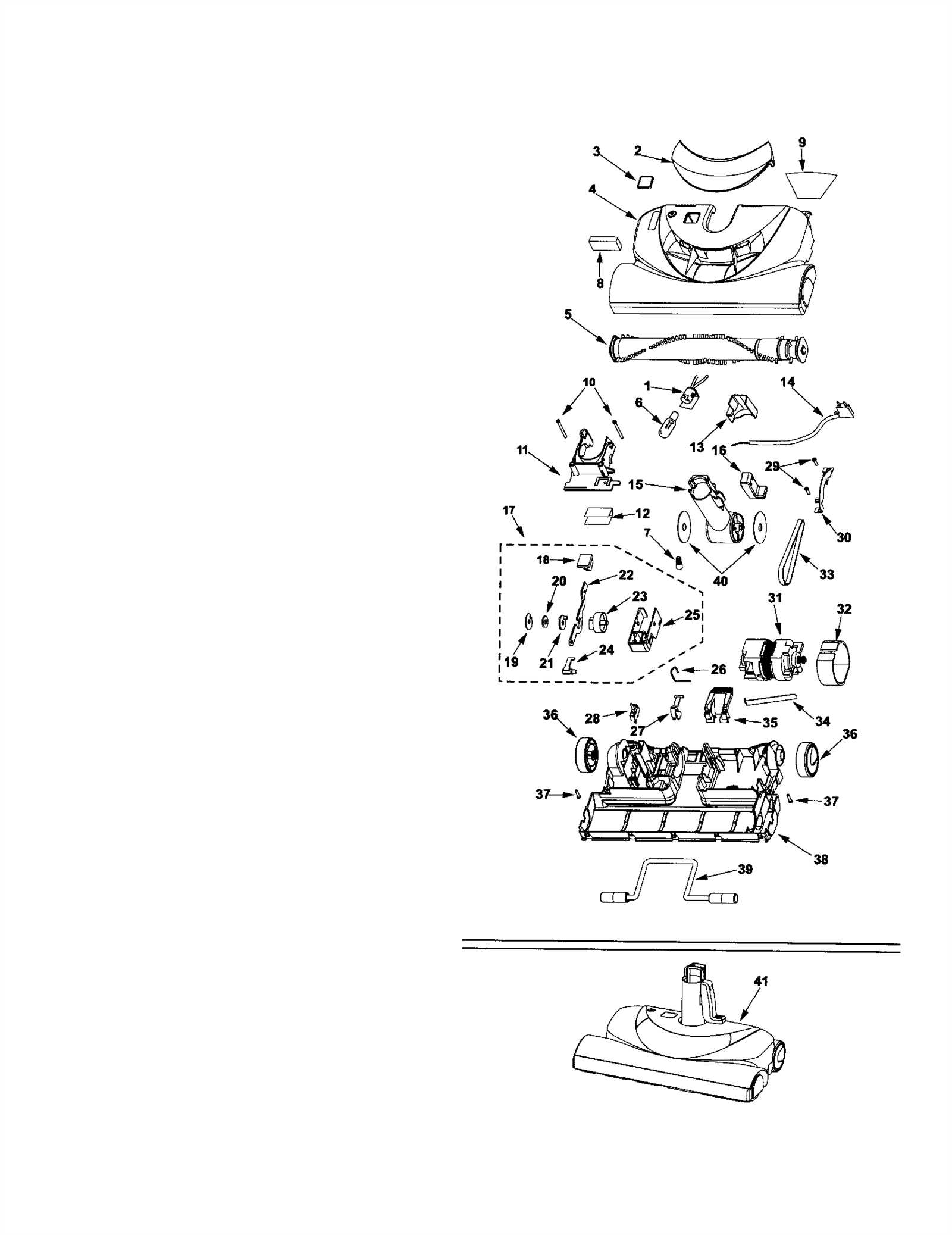

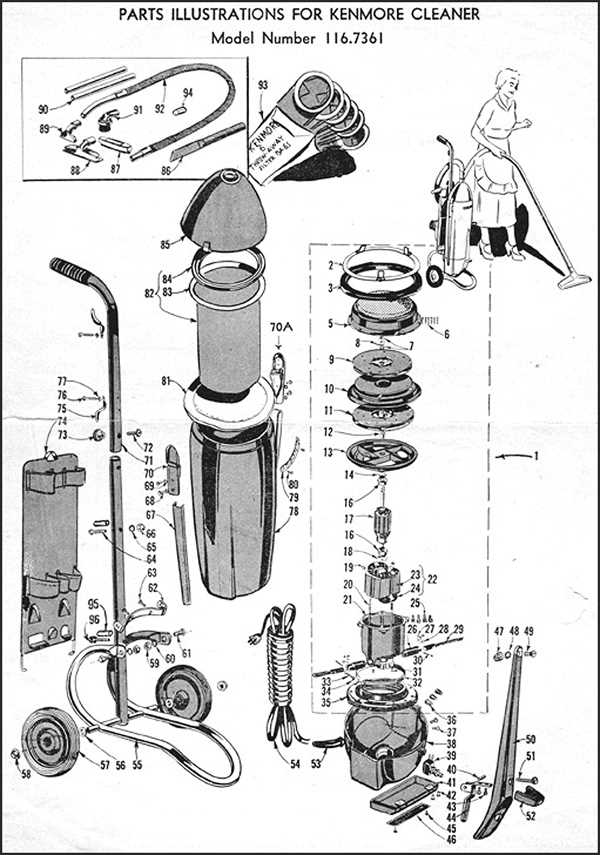

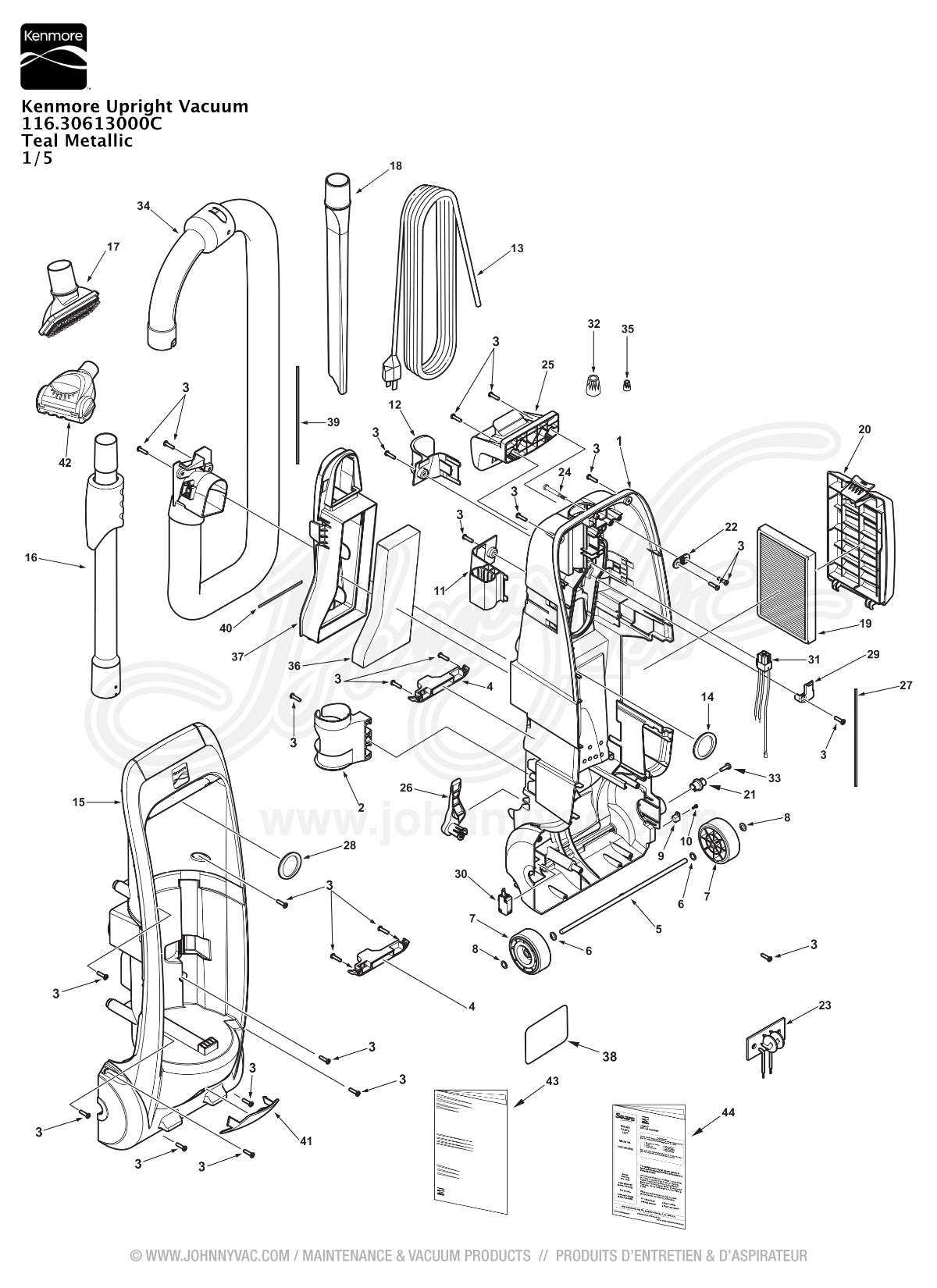

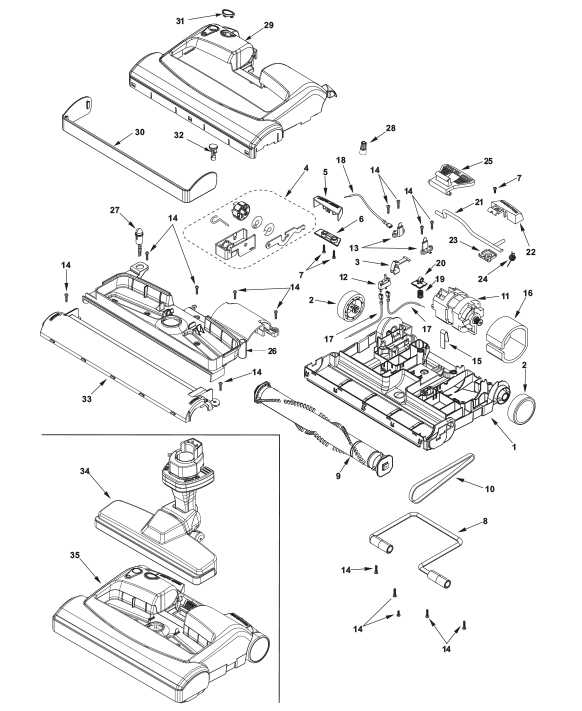

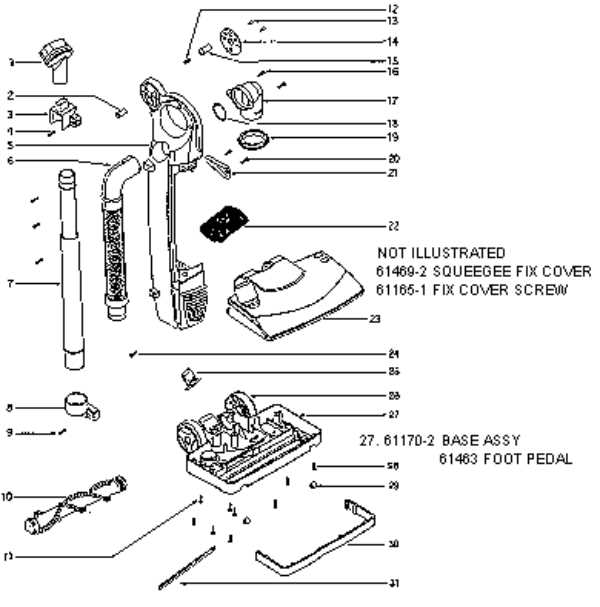

Identifying individual components within the machine allows for easy troubleshooting and quicker repairs. Each part plays a unique role, ensuring that the device operates efficiently. Understanding how these parts interact will help you make informed decisions when something goes wrong.

By following a systematic approach to repairs and replacements, you can avoid unnecessary frustration and downtime. Whether you’re replacing a filter, belt, or motor, having a clear understanding of the layout will save time and effort in the long run.

Understanding Cleaning Appliance Components

To ensure optimal functionality, it’s crucial to understand the internal components of your cleaning machine. Each element serves a specific purpose, and knowing how they work together can prevent issues before they arise. A well-maintained machine not only performs better but also lasts longer, saving you time and money on repairs.

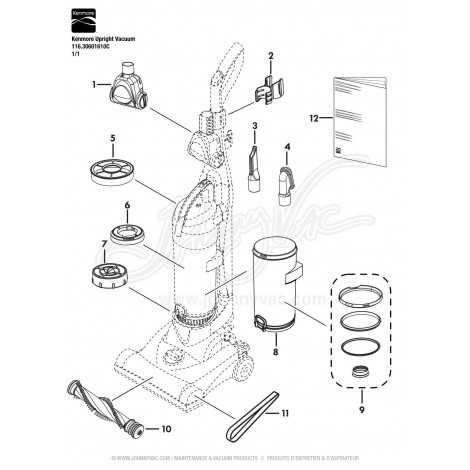

The various sections of the device include motor mechanisms, filters, and brushes, all designed to contribute to efficient operation. Understanding the role of each part allows for more effective troubleshooting and maintenance. When one component fails, recognizing the symptom can lead to quicker solutions and fewer disruptions to your cleaning routine.

Regular inspection and knowledge of your machine’s structure empower you to make informed decisions on repairs or upgrades. Familiarizing yourself with these features helps you stay proactive, ensuring that each task is completed with ease and without unexpected setbacks.

How to Identify Key Cleaning Machine Components

Recognizing the key components within your cleaning equipment is the first step toward effective troubleshooting and maintenance. Each element serves a distinct function that contributes to the overall performance of the machine. Knowing what each part does will allow you to quickly pinpoint issues and take appropriate action.

Locating the Motor and Brushes

The motor is the heart of the device, driving its cleaning capabilities. Identifying the motor’s location and understanding its role in powering other components can help you assess if it’s functioning properly. Brushes, typically found near the floor head, assist in gathering debris and moving it towards the collection area.

Recognizing Filters and Belts

Filters are essential for maintaining air quality and ensuring that dust and dirt are contained within the machine. Belts, on the other hand, connect different moving parts, enabling proper movement and action. Identifying and inspecting these components regularly can help prevent mechanical failures.

Step-by-Step Guide to Repairing Components

Repairing components within your cleaning device can seem daunting, but with a clear process, it becomes manageable. A methodical approach ensures that each part is properly addressed, preventing further damage and restoring the machine’s efficiency. Follow these simple steps for a successful repair experience.

First, identify the problem by carefully inspecting the machine. Listen for unusual noises or check for any performance issues. Once the faulty component is located, gather the necessary tools, such as screwdrivers, replacement parts, and cleaning supplies. Always turn off the device and disconnect it from any power sources before starting repairs.

After disassembling the affected section, clean the area to ensure no dirt or debris interferes with the repair. Replace the damaged component with a new or properly repaired one, following the manufacturer’s guidelines for installation. Reassemble the device carefully, checking that all parts fit securely. Finally, test the equipment to verify the repair was successful and everything is functioning as expected.