When working with heavy machinery, it is crucial to have a deep understanding of its main structures, especially those responsible for movement and stability. Each piece plays a key role in ensuring the machine operates smoothly and efficiently. Proper knowledge of these elements allows for effective maintenance, repair, and optimal performance over time.

In this section, we will explore the various components that make up the vehicle’s suspension system, focusing on their layout, function, and how to keep them in top condition. From critical connections to supportive elements, every part is designed to handle specific tasks, contributing to the overall efficiency and safety of the machine.

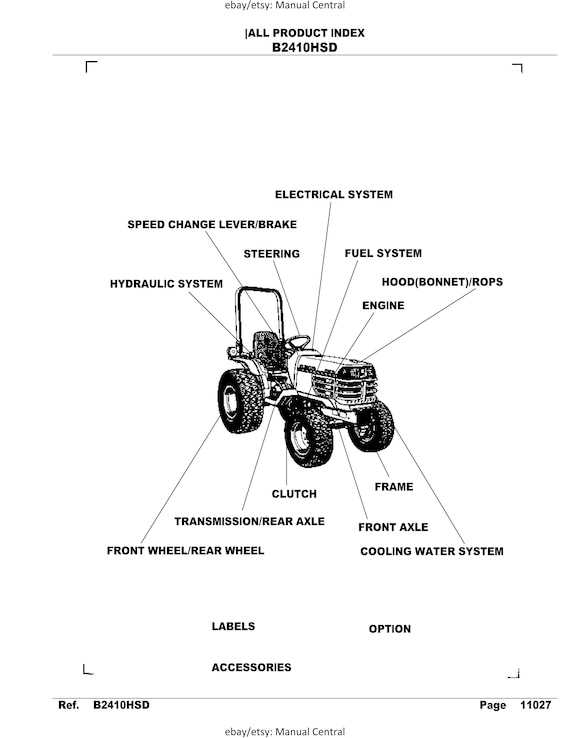

Understanding the Kubota Tractor Front Axle

The core structure responsible for supporting the weight of a machine and ensuring stable movement lies in its suspension system. This system connects the wheels to the vehicle, facilitating both steering and load distribution. Knowing how these elements interact and their role in the overall function of the vehicle is essential for proper maintenance and repairs.

Components of the Suspension System

Various components work together to maintain the machine’s balance and traction. These include essential parts like the steering mechanisms, shock absorbers, and supporting rods, each designed to handle different stresses. Understanding their function helps in diagnosing problems and ensures timely repairs.

Maintenance and Repair Considerations

Regular inspection of the key elements in the suspension system is crucial to prevent wear and tear that could lead to malfunction. Proper lubrication, checking for damage, and timely replacement of any worn-out components are necessary steps to maintain the vehicle’s performance and extend its lifespan.

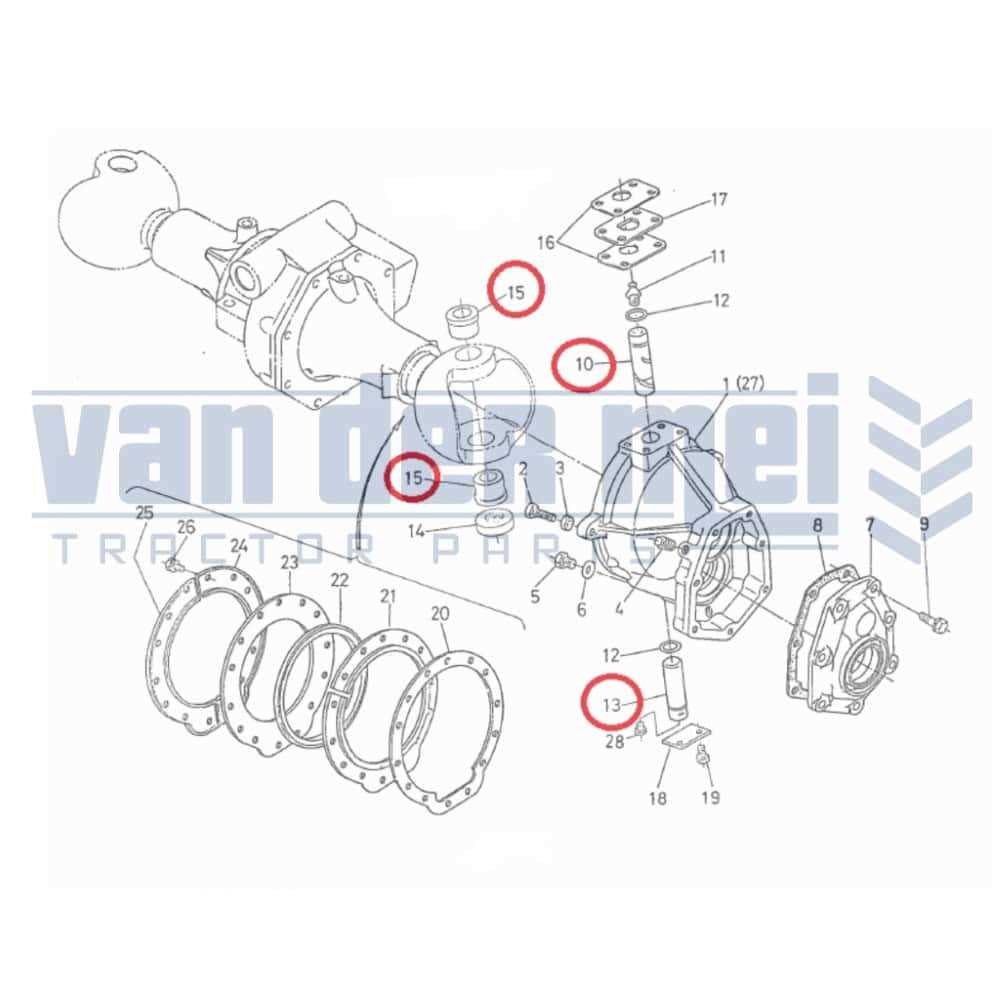

Key Components of Kubota Front Axle

The suspension and steering system of a vehicle relies on several crucial components that ensure smooth handling and durability under various conditions. Each part plays a specific role in distributing the weight of the machine and maintaining proper alignment for efficient movement. Understanding these components is essential for proper function and longevity.

Essential Supporting Elements

At the heart of the system are steering arms and linkage rods, which facilitate the movement and direction of the wheels. These components are built to handle substantial stress, ensuring that the vehicle remains responsive and stable even in demanding environments. Proper care and inspection are necessary to keep them in optimal condition.

Structural and Connecting Components

Additional structural elements like kingpins and spindles serve as key connectors, holding the wheels in place and allowing for safe rotational movement. These components work in tandem with other parts to prevent misalignment and to ensure that each part operates seamlessly with the others, providing maximum stability and reliability.

How to Maintain Kubota Front Axle Parts

Proper maintenance of key structural components ensures a machine runs efficiently and safely over time. Regular checks and timely interventions prevent unnecessary damage, reducing downtime and repair costs. Maintaining these essential elements allows for better performance and longevity of the vehicle.

First, regular inspection of all steering mechanisms and linkage components is vital. Look for signs of wear, such as cracks or loose connections, and ensure that all fasteners are properly tightened. Replacing worn-out parts promptly prevents more severe issues from developing.

Next, keep the supporting rods and spindles well-lubricated to avoid friction and excessive wear. Use the recommended lubricants for each component to ensure smooth movement and to prevent premature failure. It’s also essential to check for any signs of rust or corrosion, as these can weaken the structural integrity of the system.

Lastly, ensure that all moving parts are regularly cleaned to remove dirt and debris. Accumulated grime can impair function and lead to breakdowns. Implementing a routine cleaning schedule helps to maintain performance and prevents damage from contaminants.