When it comes to maintaining heavy machinery, having a clear understanding of its internal components is essential. Knowing where each piece fits and how it functions ensures proper operation and minimizes downtime. This guide aims to provide insights into the essential parts of your equipment and how they interact, offering you the knowledge needed for effective troubleshooting and repairs.

Proper maintenance relies on identifying the correct components quickly. With an organized reference of the machine’s structure, any potential issues can be diagnosed more easily. Whether you’re replacing worn-out parts or performing regular upkeep, knowing where to look is half the battle.

In this article, you’ll discover how to navigate detailed visual aids that outline the layout and function of various sections. These tools can significantly improve your efficiency, helping you tackle repairs with confidence and accuracy.

Understanding the Kubota B7800 Components

Having a solid grasp of the essential elements within your tractor can make a significant difference when it comes to maintenance and repairs. Every machine is made up of various systems that work together to ensure smooth operation. Recognizing these components and their respective roles is the first step in keeping your equipment running at its best.

Key Components of the Tractor

Among the most critical parts are the engine, transmission, and hydraulic system. These work in harmony to provide the necessary power and functionality. The engine drives the entire system, while the transmission helps transfer power to the wheels. The hydraulic system, on the other hand, is responsible for lifting and controlling implements that assist with different tasks.

Maintenance and Care

Routine checks on these major components can extend the lifespan of your machine and prevent costly repairs. Regular inspection of the engine and fluid levels, alongside timely replacement of any damaged components, is key to maintaining optimal performance. Understanding the layout of the essential parts allows for easier diagnostics and more effective intervention when issues arise.

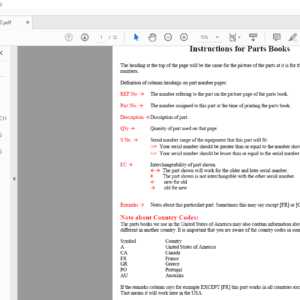

How to Use the Kubota B7800 Parts Diagram

Efficiently navigating your machine’s internal layout can make repairs and maintenance much easier. A visual representation of all the essential components allows you to identify each part quickly, facilitating smooth troubleshooting and part replacements. Understanding how to use these references will save time and effort when dealing with mechanical issues.

Identifying Key Areas

Start by familiarizing yourself with the main sections of the machine. These usually include the engine compartment, transmission area, and hydraulic system. Each section will have its own set of components listed clearly, which will help you pinpoint any specific parts that need attention. Pay attention to the labels and visual indicators to avoid confusion and ensure accuracy in your work.

Step-by-Step Troubleshooting

Once you’ve identified the area requiring maintenance, use the reference to trace the connections between different components. This will give you a clearer understanding of how each part interacts within the system. By following the correct sequence, you can easily isolate the issue and either repair or replace the damaged component. This systematic approach prevents unnecessary disassembly and improves efficiency during the repair process.

Common Issues and Parts Replacement Tips

Maintaining your machine involves recognizing frequent mechanical problems and knowing when and how to replace worn-out or damaged components. Understanding these issues and preparing for timely part replacements can prevent more serious damage and keep your equipment in optimal working condition.

Common Mechanical Problems

Over time, certain issues tend to arise more frequently due to wear and tear. Here are some of the most common problems that may require attention:

- Engine overheating: This could be due to coolant leaks or a malfunctioning radiator.

- Fluid leaks: Check hoses, seals, and gaskets regularly to prevent leaks from affecting performance.

- Worn-out belts and pulleys: Overuse and age can cause these parts to lose tension or break.

- Clogged filters: Dirty air and fuel filters can reduce engine efficiency and increase wear.

Tips for Efficient Part Replacement

When replacing any worn components, keep the following tips in mind:

- Use high-quality replacements: Ensure the new parts are of equal or better quality than the original to maintain optimal performance.

- Follow manufacturer guidelines: Always refer to the machine’s manual for specific replacement procedures and intervals.

- Regular inspections: Routine checks can catch problems early before they require major repairs.

- Proper tools: Using the right tools for the job prevents damage to surrounding components.