htmlEdit

Understanding the intricate components of a small agricultural vehicle is essential for proper maintenance and troubleshooting. Every machine is made up of various essential elements that work in unison to ensure efficiency and reliability during operation. A comprehensive view of these parts allows for informed decisions regarding care, repair, and upgrades.

Effective maintenance relies on knowledge of the specific roles each part plays in the overall system. Recognizing how individual components contribute to the performance of the vehicle can help avoid costly repairs and downtime. Whether addressing mechanical failures or performing routine inspections, understanding the structure is key to longevity.

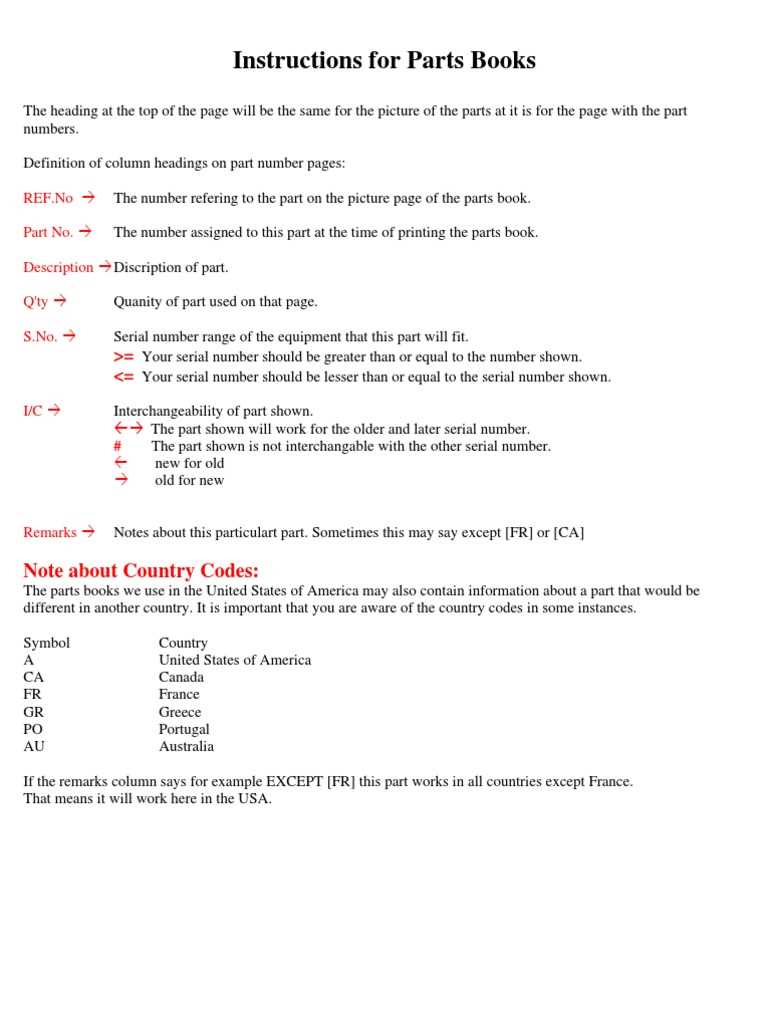

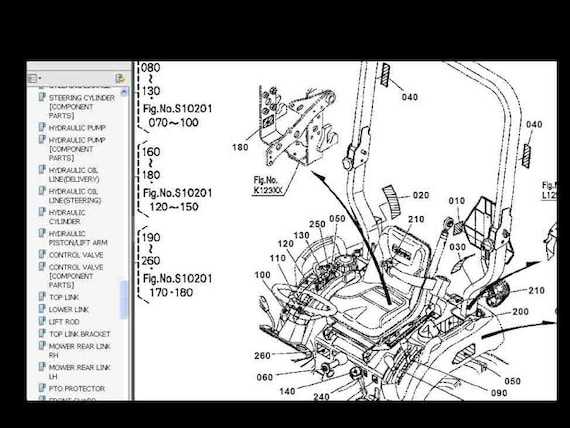

Detailed guides and organized visual resources provide clarity for users who wish to explore the internal workings. Such resources enable both professionals and hobbyists to identify areas needing attention and select the right solutions. In this section, we break down the critical elements for easy reference.

htmlEdit

Key Components of the Tractor

Every vehicle, especially those designed for heavy-duty tasks, is built around a core set of essential elements that ensure proper function and efficiency. Understanding these fundamental components allows users to make informed decisions when it comes to repairs, maintenance, and upgrades. Each part is integral to the overall performance and longevity of the machine.

Engine and Power Transmission

The engine serves as the heart of the machine, generating the power needed to drive the entire system. Paired with the power transmission, it ensures that energy is effectively distributed to various working parts. The combination of these systems determines the overall operational capacity and reliability.

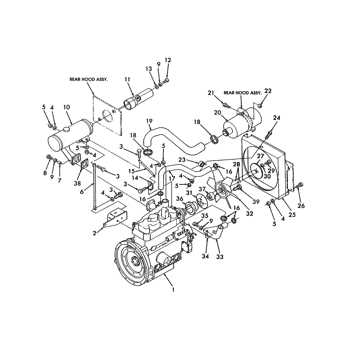

Chassis and Hydraulic Systems

The chassis provides the structural support, housing many critical components such as the suspension and frame. Meanwhile, the hydraulic systems play a crucial role in powering attachments and other functional elements. These systems work in tandem to deliver the necessary force for various tasks, from lifting to pushing.

htmlEdit

Understanding the Tractor’s Structure

The structure of any agricultural vehicle is a combination of several interconnected systems working together to ensure stability, mobility, and functionality. Each element, from the frame to the auxiliary components, plays a crucial role in maintaining the machine’s overall performance. A deep understanding of this layout is essential for optimizing operation and simplifying repairs.

The chassis serves as the foundation, providing the necessary framework to support the engine, transmission, and other key systems. This structural element must be durable and robust to withstand the stresses of various tasks. On top of this foundation rests the hydraulic system, which powers many of the attachments and mechanisms responsible for movement and lifting functions.

By comprehending the way these parts interact, operators are better equipped to identify potential issues, perform routine inspections, and maintain their vehicles effectively. Knowing the roles and connections of each element aids in ensuring smooth operation and enhances the machine’s longevity.

htmlEdit

Maintenance and Repair Considerations

Regular upkeep and timely repairs are essential for ensuring the longevity and efficiency of any mechanical machine. Proper maintenance can prevent breakdowns, reduce the need for costly repairs, and keep the vehicle running smoothly for years. Understanding the key aspects of care is vital for extending the life of the equipment and avoiding unexpected malfunctions.

There are several factors to consider when performing maintenance and addressing potential issues:

- Routine Inspections: Regularly checking the engine, transmission, and other key components for signs of wear or damage is crucial. Early detection of problems can prevent more serious issues from arising.

- Fluid Levels: Ensuring that all fluids, such as oil, coolant, and hydraulic fluid, are at optimal levels helps maintain proper function and prevent overheating or mechanical failure.

- Lubrication: Proper lubrication of moving parts reduces friction, minimizing wear and tear. Regular greasing of joints, bearings, and other parts is essential for smooth operation.

- Component Alignment: Misaligned parts can lead to inefficiency and potential damage. Ensuring proper alignment of the various systems within the machine is important for maximizing performance.

When it comes to repairs, replacing worn-out or damaged components with quality alternatives is key to maintaining operational efficiency. Always ensure that replacement parts are compatible with the machine to avoid future complications.