Understanding the structure and key components of your machine is essential for efficient maintenance and repairs. A well-organized map of all parts helps you quickly locate and identify necessary elements for troubleshooting or replacement. This guide provides a comprehensive look into how to effectively use such resources for your equipment.

Effective management of your machine’s components involves recognizing each piece’s function and position. Proper knowledge ensures faster repairs and reduces the risk of errors during the maintenance process. Learning to read and interpret detailed charts can save both time and money in the long run.

In this article, we will explore the most useful strategies for navigating a detailed reference guide and show you how to identify, locate, and understand each key part of your equipment. Whether you’re a professional mechanic or a dedicated owner, this information will prove invaluable for maintaining your machine in top condition.

Kubota BX23S Parts Overview

When it comes to maintaining your machine, knowing its individual components is crucial. Each element plays a specific role in ensuring smooth operation, and understanding their function can help with both maintenance and troubleshooting. This section provides a general overview of the key sections and components, giving you the knowledge needed to identify and manage them effectively.

Major Components of the Machine

The machine consists of several main sections, each responsible for different functions. The engine, drivetrain, and hydraulic systems work together to provide power and mobility, while smaller components such as electrical parts and controls ensure efficient operation. Understanding how these elements work in harmony allows for better care and timely replacements when necessary.

Identifying and Replacing Components

Identifying and replacing worn or damaged parts is an essential skill for anyone managing machinery. By understanding the layout and functions of each section, you can quickly spot potential issues before they escalate. Whether it’s a broken link or a malfunctioning sensor, having a solid grasp of your machine’s design can streamline the repair process and help maintain its longevity.

Understanding the Parts Layout

Getting acquainted with the layout of your equipment’s components is essential for effective maintenance. A well-organized map of the different sections and pieces allows you to quickly identify and address any issues that arise. This section will guide you through understanding the key layout elements and how to navigate them efficiently.

Key Sections of the Machine

The overall structure is divided into several key areas, each serving a distinct function. Recognizing these major sections can help you focus on specific areas when troubleshooting or performing repairs. Below are the primary sections you will encounter:

- Engine area: Includes the engine, fuel system, and related components.

- Hydraulic system: Controls movement and lifting functions.

- Transmission: Manages power distribution to the wheels.

- Electrical system: Provides power to lights, sensors, and other controls.

- Steering and suspension: Ensures smooth maneuverability and stability.

How to Read the Layout

Once you are familiar with the sections, it’s important to know how to read the detailed layout. These visual aids typically use standardized symbols and labels to represent each component’s function and location. Understanding these conventions is crucial for identifying specific elements without confusion. Keep the following tips in mind:

- Start by familiarizing yourself with the legend or key, which explains the symbols.

- Look for color coding that may indicate specific systems, such as hydraulics or electrical components.

- Use the reference numbers to cross-check with the equipment’s manual for part identification.

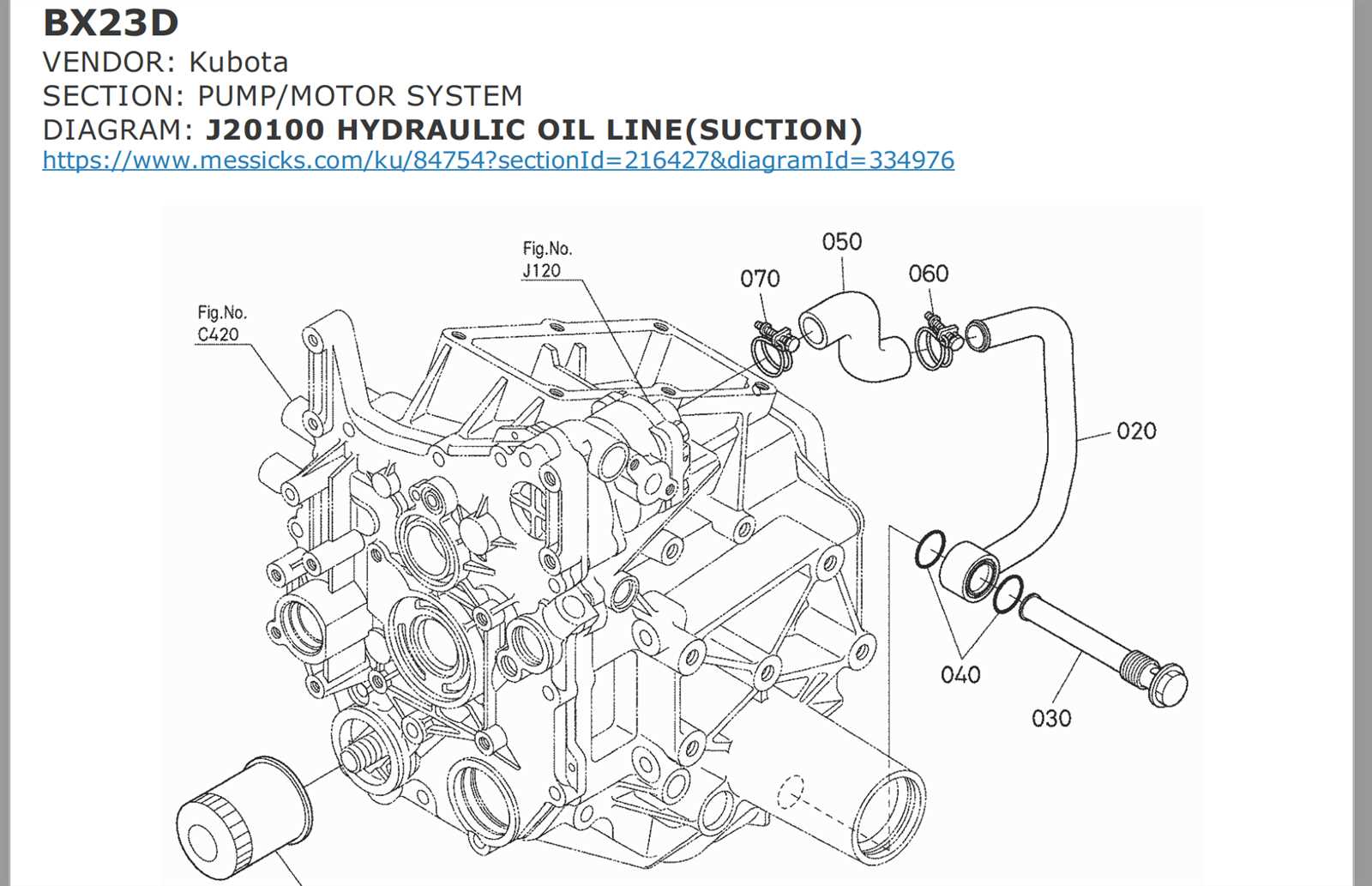

How to Use the Parts Diagram

Being able to effectively use a detailed schematic is key to performing maintenance and repairs on your equipment. These visual tools provide a clear layout of each section, allowing you to quickly identify components, locate damage, and find suitable replacements. In this section, we will explore how to navigate and interpret these resources to streamline your work process.

The first step is to understand the symbols and labels used in the chart. Most guides use standardized representations to show various elements such as connectors, bolts, and sensors. By becoming familiar with these symbols, you will be able to quickly locate the necessary components in the visual layout. Pay attention to the reference numbers, as these often correspond with part numbers in the manual or inventory lists.

Another useful aspect of these schematics is their organization by system or area of the machine. They typically break down components into categories such as hydraulic, electrical, or mechanical systems, allowing you to focus on specific areas when troubleshooting or replacing parts. Using this system, you can quickly pinpoint the exact location of the part you need to inspect or replace, ensuring a more efficient maintenance routine.