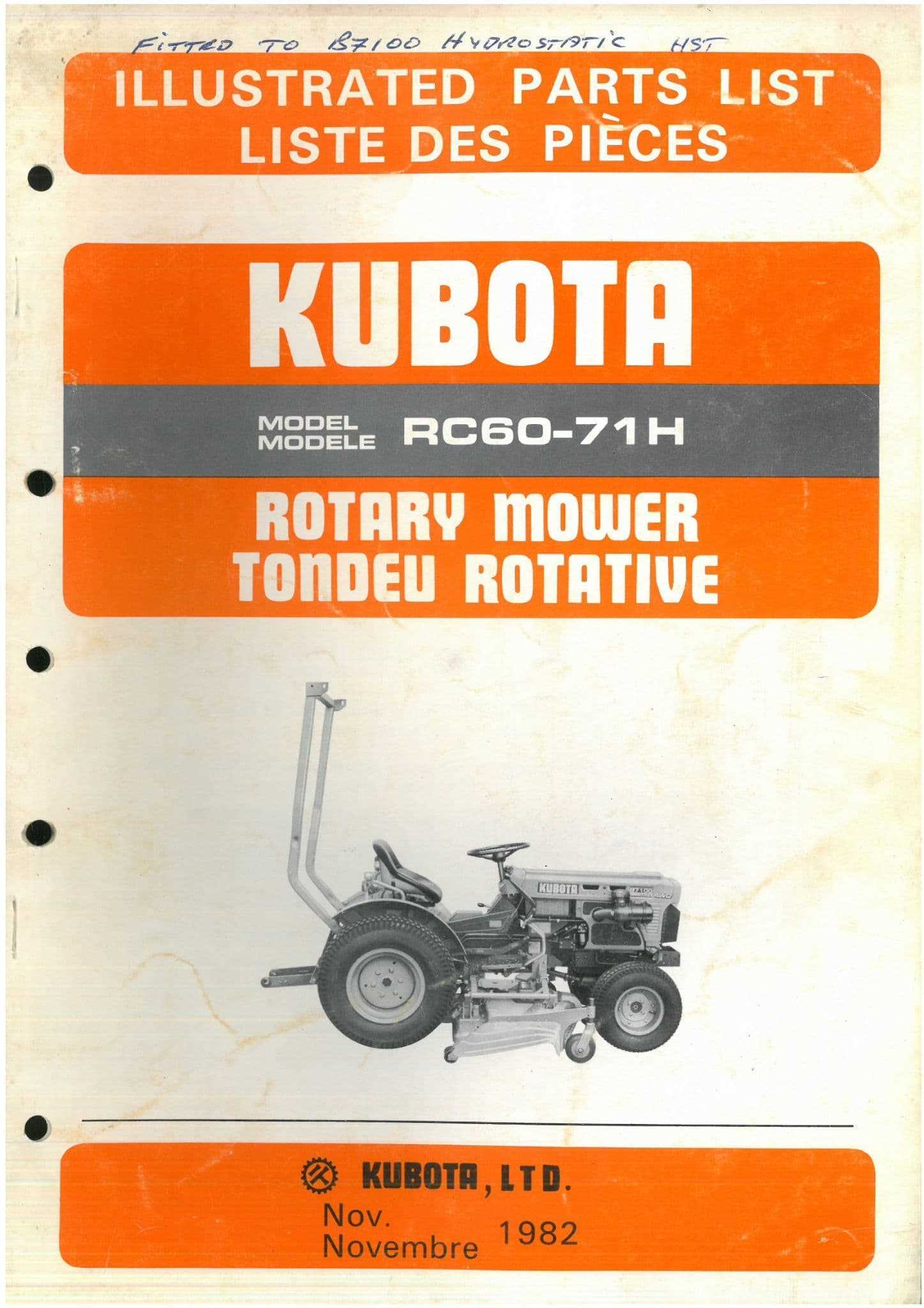

For any tractor owner, understanding the layout of machine components is crucial for efficient maintenance and repair. Proper knowledge helps identify issues early, ensuring your equipment operates smoothly and remains durable over time. A clear understanding of each part’s function makes troubleshooting and replacements faster and more effective.

Maintaining optimal performance relies on recognizing when certain parts need attention. Whether it’s replacing worn-out components or upgrading for better efficiency, knowing where to look and what to look for can save both time and money.

In this guide, we will explore how to navigate and interpret the detailed illustrations of machine components, offering insights into key areas and essential steps for upkeep. Understanding these visual references is an invaluable tool for any enthusiast or professional working with heavy machinery.

Understanding the Tractor Components

Every piece of machinery consists of various key elements that work together to ensure smooth functionality. Gaining a comprehensive understanding of these individual components is essential for anyone looking to maintain, repair, or upgrade their equipment. Each part has a specific role, and recognizing how they interact allows for better decision-making when it comes to maintenance or troubleshooting.

The major components can generally be divided into different categories, each serving a unique purpose within the system:

- Engine system: The heart of the machine, responsible for generating the power required for operation.

- Transmission components: These elements control the distribution of power from the engine to the wheels, ensuring proper movement and speed regulation.

- Steering and control systems: They allow the operator to direct and control the machine effectively, providing maneuverability and precision.

- Hydraulic system: This system controls various mechanical functions, such as lifting and tilting, by using fluid pressure.

Familiarity with these major sections will help identify where issues might arise and which elements need attention. Recognizing the correct function of each system aids in making informed decisions about repairs or replacements.

By understanding the key components and their relationships, one can maintain a higher level of efficiency and ensure the long-term reliability of the machine.

How to Read the Component Layout

Understanding technical illustrations that depict machine elements is essential for any equipment owner. These visuals serve as detailed maps, showing the exact location and relationship between the various components. By interpreting these layouts correctly, users can easily identify specific parts, their functions, and how they connect within the overall system.

The first step in reading these illustrations is to familiarize yourself with the legend or key. This section explains the symbols used to represent different components and their respective functions. Common symbols may include various shapes and lines indicating movement, flow, or connection points.

Next, look for grouping: Many layouts organize elements by function, grouping similar components together. For example, all elements related to the engine may be shown in one section, while the steering system is placed in another. This method of grouping makes it easier to locate specific systems when troubleshooting or performing maintenance tasks.

Finally, focus on the directional flow: Understanding how energy, fluids, or signals flow through the machine will help you pinpoint issues more efficiently. Arrows or lines often indicate movement, and following these paths can provide insight into the machine’s operation and potential problem areas.

By mastering the art of reading these layouts, operators can diagnose issues quickly and make informed decisions about replacements or repairs.

Common Replacement Components for Tractors

Over time, certain elements of a machine naturally wear out due to frequent use, exposure to harsh conditions, or age. Knowing which components are most likely to need replacement can save you time and effort when performing maintenance. Some parts are designed to be easily swapped out, ensuring minimal downtime and continued performance.

Among the most commonly replaced components are:

- Filters: Oil, air, and fuel filters are critical to maintaining proper function and preventing dirt or debris from damaging the internal systems.

- Belt systems: These are often subject to wear and tear, especially in high-stress areas like the engine and transmission. Regular inspection is crucial to avoid breakdowns.

- Battery: Over time, the battery’s ability to hold a charge can diminish, affecting the machine’s starting power and overall performance.

- Hydraulic hoses and seals: Hydraulic systems can suffer from leaks, making it essential to regularly replace worn-out hoses and seals to maintain fluid pressure and system efficiency.

- Plugs and gaskets: These small but vital components help prevent leaks and ensure that systems remain sealed. Replacing them at the first sign of wear can prevent more serious issues.

Maintaining these key components ensures that the machine continues to operate smoothly and reliably, reducing the chances of unexpected breakdowns and costly repairs. Regularly replacing these common parts as part of a maintenance routine will extend the life of the equipment and improve its overall performance.