Understanding the internal structure of a small engine is essential for efficient operation and repair. Knowing how each element works and connects can help you identify potential issues quickly. This section will explore the key components of a well-known engine and provide insights into their functions.

Proper maintenance and a clear understanding of the system are vital for ensuring the longevity of the machinery. This guide will break down the primary sections, highlighting the role of each component and its significance in the overall system.

By familiarizing yourself with the layout and functions of the engine’s individual parts, you can tackle troubleshooting and repairs more effectively. From basic maintenance tasks to more complex repairs, knowing the system inside and out is the first step toward achieving optimal performance.

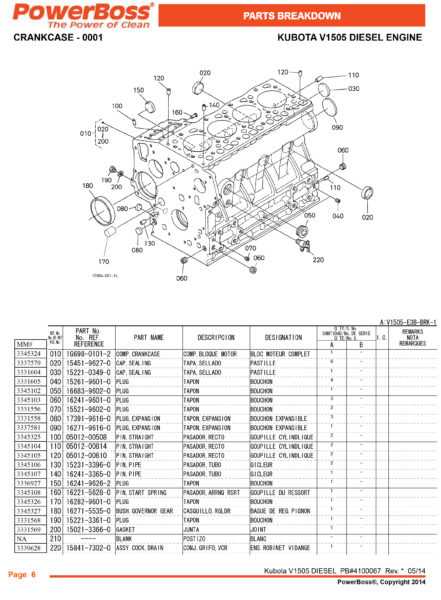

Understanding the Engine Components

Every engine is composed of numerous elements that work together to ensure smooth and efficient operation. These parts are designed to perform specific tasks, contributing to the overall performance and reliability of the machine. Understanding how these components interact is key to maintaining, troubleshooting, and repairing the engine.

Key Functional Elements

The core components of the engine serve distinct purposes that are essential for its operation. The crankshaft, for example, plays a pivotal role in converting the energy from combustion into mechanical motion. The cylinder head houses the intake and exhaust valves, helping regulate the flow of gases into and out of the combustion chamber. Additionally, the fuel system ensures that the right amount of fuel is delivered to maintain efficiency and power output.

Critical Systems for Optimal Performance

In addition to the core components, there are various systems that support the engine’s performance. The cooling system prevents overheating by circulating coolant through the engine. Similarly, the lubrication system ensures that all moving parts are adequately oiled, reducing friction and wear. Proper functioning of these systems is necessary for maintaining the engine’s health and extending its service life.

Key Parts in the Engine Assembly

The overall function of an engine relies heavily on the collaboration of various key components. Each part is designed to fulfill a specific role, ensuring optimal performance and efficiency. Understanding the primary elements of the assembly is crucial for maintenance, repairs, and troubleshooting.

Primary Components

The following are essential elements in the engine assembly:

- Crankshaft – Converts energy from combustion into mechanical motion.

- Cylinder Block – Houses the cylinders and provides structural support.

- Camshaft – Controls the timing of the valves’ opening and closing.

- Fuel Pump – Delivers fuel to the engine in the right quantity for combustion.

- Timing Gear – Synchronizes the rotation of various engine components.

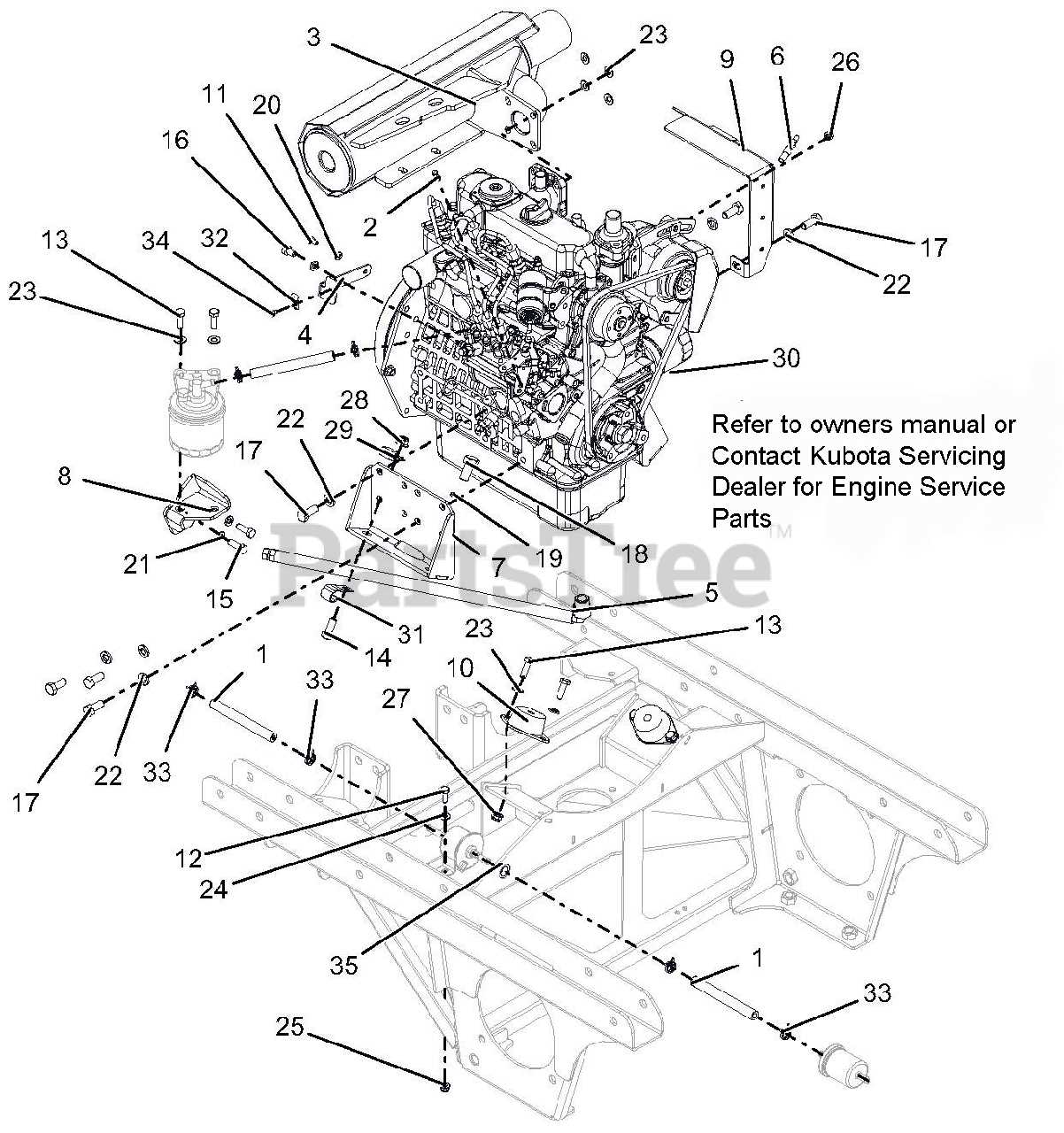

Supporting Systems

Alongside these core components, several systems support the engine’s functionality:

- Cooling System – Maintains the engine’s temperature by circulating coolant.

- Lubrication System – Reduces friction and wear on moving parts.

- Electrical System – Powers the ignition, fuel injection, and other electrical components.

Maintenance Tips for Engine Components

Regular maintenance is crucial for ensuring the longevity and efficiency of any engine. Proper care helps prevent breakdowns and extends the operational life of essential elements. By following key maintenance practices, you can avoid costly repairs and keep the engine running smoothly.

Routine Inspections

Performing regular inspections of the engine’s core components is a great way to catch issues before they become serious problems. Check for:

- Leaks – Ensure that there are no signs of oil or coolant leaks around the engine block.

- Wear and Tear – Look for any visible damage or excessive wear on moving parts like belts and hoses.

- Debris – Keep the intake and exhaust areas clear of dirt, dust, or other debris that may cause blockages.

Fluid Management

Maintaining proper fluid levels is vital to the smooth operation of the engine. Regularly check and change:

- Oil – Use the manufacturer’s recommended oil type and change it at the suggested intervals to keep moving parts lubricated.

- Coolant – Ensure the cooling system is properly filled with the appropriate coolant to prevent overheating.

- Fuel – Use clean, high-quality fuel to prevent clogging in the fuel system.