Maintaining machinery requires a clear understanding of its internal structure. Identifying the components and understanding how they fit together can simplify repairs and upgrades. Proper knowledge of this layout helps ensure efficient maintenance and reduces downtime.

In this guide, we will break down the essential elements of a specific tractor model, providing you with a comprehensive visual representation. This will assist in locating parts and understanding their functions within the system.

By familiarizing yourself with the detailed layout, you can confidently address any mechanical issues, whether it’s a minor fix or a major overhaul. Understanding the various sections of your equipment will make troubleshooting and replacement processes far easier.

Understanding Tractor Component Layout

Effective maintenance begins with understanding the overall configuration of the machine’s system. A clear map of how different elements are positioned within the vehicle ensures that repairs and replacements are done accurately and efficiently. By studying the layout, operators can easily locate the necessary components for servicing or upgrades.

Key Elements of Tractor Layout

Each machine is designed with a specific arrangement of its key parts. Understanding these sections allows you to identify where specific components are located, such as the engine, transmission, and other vital systems. This knowledge helps in diagnosing problems faster and with greater precision.

How Layout Affects Functionality

The way components are organized impacts the overall performance and ease of repair. A well-structured system allows for quicker troubleshooting and minimal disruption to operation. Knowing how the components work together helps in making informed decisions during maintenance and part replacement.

Common Replacement Parts for Tractor Maintenance

Routine maintenance often requires replacing certain components that experience wear over time. Understanding the most common parts that need replacement can help in ensuring the longevity and optimal performance of the equipment. Some components are more prone to wear and tear due to frequent usage or environmental factors, making them essential to monitor and replace as needed.

Engine belts, filters, and seals are some of the most commonly replaced items. These components are vital for the smooth operation of the machine and should be checked regularly for any signs of damage or degradation. Additionally, hydraulic hoses and the battery are often subject to replacement to avoid any disruptions in functionality.

Another critical area of focus is the transmission system, where parts such as gears and bearings may need replacement after prolonged use. Identifying the symptoms of failure early can prevent more severe damage and reduce the overall maintenance cost.

How to Read Tractor Component Layout

Understanding a machine’s component map is crucial for identifying specific parts and their functions. Learning how to interpret these visual guides allows for easier identification and troubleshooting when performing maintenance or repairs. These diagrams are structured to show how various components are connected and how they interact with one another.

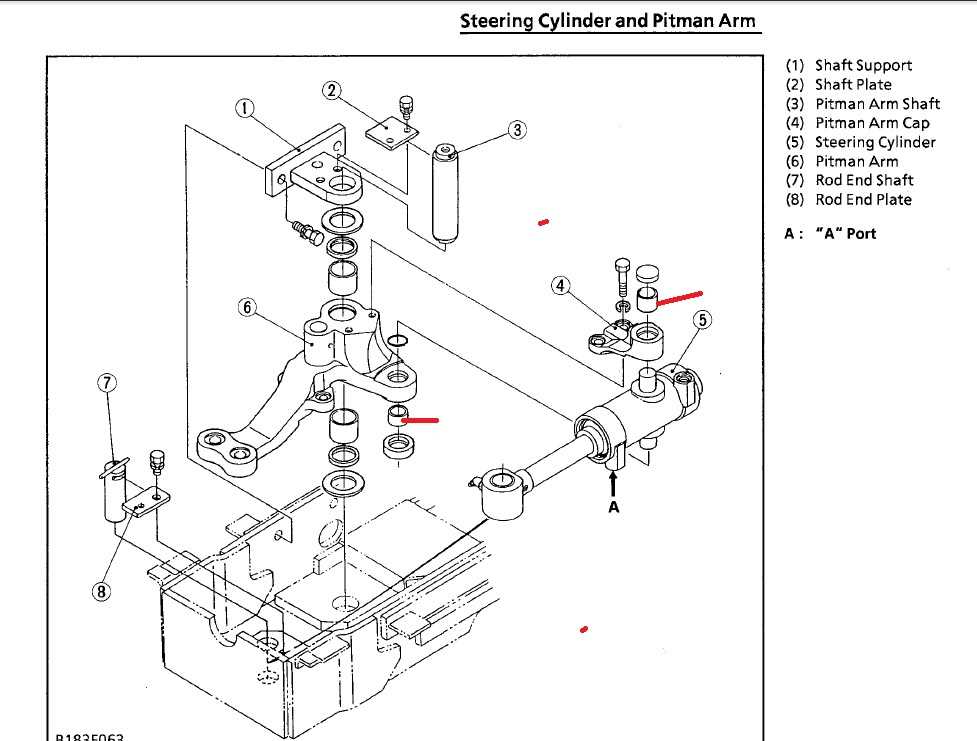

To begin with, focus on the overall layout of the system. Each section is labeled with numbers or codes that correspond to specific parts. These references help you easily locate the part in question when looking for a replacement or during an inspection. Pay attention to the shape, position, and orientation of components, as these visual cues provide important information for assembly and disassembly processes.

Another key aspect is understanding the various symbols and color codes used in these diagrams. These visual markers often indicate different functions or types of materials, making it easier to differentiate between similar-looking components. By mastering the diagram’s key, you’ll be able to navigate it effectively and efficiently.