When working with heavy machinery, having a clear understanding of its internal structure is crucial. Knowing where each element is located and how they interact ensures smooth operation and easier troubleshooting. This section will break down the key components, making it simpler to identify and address potential issues.

The engine, hydraulic systems, and transmission components all play pivotal roles in the machine’s performance. Each part contributes to the overall efficiency and functionality, whether it’s for regular maintenance or specific repairs. A detailed overview of these elements is essential for anyone looking to maintain or repair their equipment with confidence.

With this guide, you will gain insights into the machinery’s inner workings, allowing for quicker identification of issues and more informed decision-making during repairs. Understanding how each segment fits into the larger picture can help avoid unnecessary complications and improve overall system reliability.

Overview of Kubota LA525 Components

Understanding the core elements of any machinery is essential for maintaining its efficiency. Each major system and part plays a critical role in ensuring the overall function of the machine. In this section, we will provide an overview of the key components, highlighting their importance in daily operations and repairs.

The machine consists of several interconnected systems, each designed to perform specific functions. These include:

- Engine Assembly: The heart of the machine, providing the necessary power for all operations.

- Transmission System: Ensures power is transferred from the engine to the wheels, enabling movement.

- Hydraulic System: Powers key functions such as lifting and moving attachments, critical for versatility.

- Electrical System: Manages power distribution for various electrical components, ensuring smooth operation.

- Fuel System: Responsible for storing and delivering fuel to the engine for combustion.

Each of these components works in tandem to provide the necessary support for tasks ranging from routine operations to complex tasks requiring specific attachments. Understanding the layout and functions of these systems helps in diagnosing issues, performing preventative maintenance, and extending the machine’s lifespan.

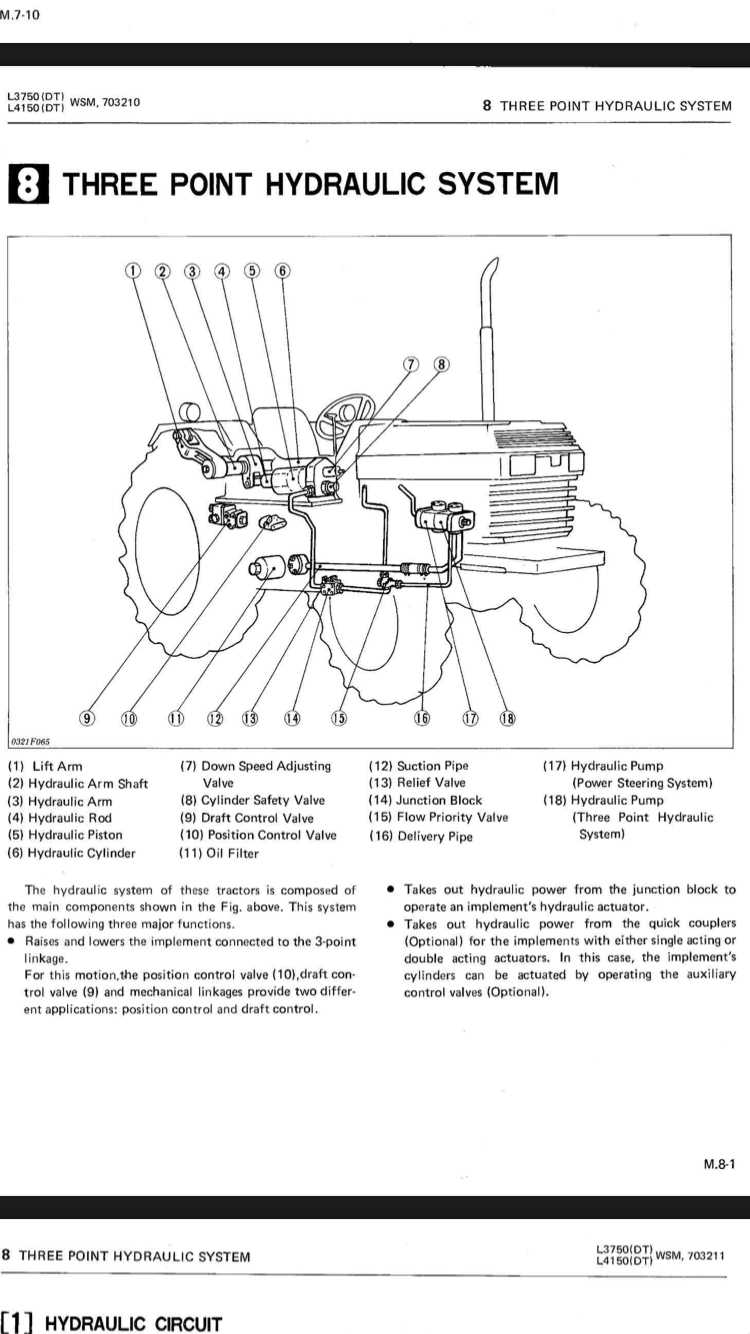

Understanding the Hydraulic System Layout

The hydraulic system is a vital component in many heavy-duty machines, responsible for transmitting power through fluid. Its layout dictates how fluid is directed to various parts of the machine to perform tasks such as lifting, steering, or powering attachments. This section will explore the key elements of the hydraulic system and how they work together to ensure smooth operation.

Key Hydraulic Components

At the heart of the hydraulic system are several crucial components that enable efficient power transfer. These include the hydraulic pump, valves, cylinders, and hoses. Each of these parts serves a unique role:

- Hydraulic Pump: Converts mechanical energy into hydraulic power, driving fluid through the system.

- Valves: Control the flow and direction of fluid, allowing the operator to control the machine’s movements precisely.

- Hydraulic Cylinders: Convert hydraulic energy into linear force, enabling the movement of parts like arms and attachments.

- Hoses and Fittings: Carry the hydraulic fluid between components, ensuring a continuous flow of power.

How the System Operates

The hydraulic system relies on the controlled flow of fluid to perform tasks. When the operator activates a lever or switch, it signals the valves to direct fluid to the appropriate cylinder. The pressure of the fluid in the cylinder then moves the connected part, such as a lift arm or bucket. By adjusting the flow and pressure, the operator can control the force and speed of the movement.

Proper maintenance of the hydraulic system ensures that all components function at peak efficiency, preventing breakdowns and extending the lifespan of the machinery.

Key Parts for Tractor Maintenance

Proper maintenance is crucial to keep any machinery running smoothly. Regular checks and timely replacement of worn-out components can significantly enhance the longevity and performance of the equipment. This section highlights the essential parts that require attention to ensure reliable operation.

Essential Components for Routine Care

Several critical systems should be maintained regularly to prevent costly repairs or unexpected breakdowns. The most important elements to focus on include:

- Engine Oil and Filters: Ensuring the engine runs smoothly is essential, and clean oil and filters are vital to maintaining performance.

- Hydraulic Fluid: The hydraulic system relies on clean, adequately filled fluid to maintain power transmission and functionality.

- Fuel Filters: Clean fuel filters prevent contaminants from reaching the engine, ensuring efficient combustion and preventing damage.

- Belts and Pulleys: These components work together to transfer power, and regular checks can help prevent system failures.

- Battery and Electrical System: Proper functioning of the battery and electrical components is necessary for starting the engine and operating electrical systems.

Signs of Wear and When to Replace

Monitoring the performance of these components can help detect early signs of wear. Regularly checking for leaks, unusual noises, or reduced functionality is key to identifying when parts need replacing. Maintaining these critical components ensures the machine performs reliably and efficiently, avoiding downtime during important tasks.