When maintaining and repairing a tractor, understanding its internal structure is essential. Having a clear representation of how various components fit together can greatly simplify troubleshooting and replacement tasks. This guide aims to provide you with the necessary resources to navigate the intricate system of a heavy-duty machine, ensuring efficient upkeep and minimal downtime.

Accurate identification of each element plays a crucial role in ensuring the correct part is selected when replacements are needed. Whether you’re a professional mechanic or a dedicated owner, understanding the system can make all the difference in maintaining peak performance.

By learning how to read and interpret these helpful visual guides, you can gain a better grasp of the machine’s design. This knowledge will allow you to handle maintenance and repairs more effectively, ensuring your equipment runs smoothly for years to come.

Understanding the Kubota M7060 Parts

Every heavy-duty machine relies on a complex arrangement of components that work in unison to perform various tasks. Knowing how each element functions and fits into the overall design allows for better maintenance and effective troubleshooting. The key to prolonging the life of a machine is understanding its mechanical structure and how individual elements contribute to its operation.

Key Components and Their Functions

The engine, transmission, and hydraulic system are the primary elements that drive the performance of any machinery. Each system relies on specific components, such as belts, pumps, and filters, to ensure smooth operation. Understanding the role of these parts within the overall framework allows you to identify issues more easily and address them before they lead to more serious malfunctions.

Why Component Identification is Essential

Properly identifying components ensures the right part is replaced or repaired, avoiding costly errors and unnecessary downtime. Having a comprehensive view of all elements within the system helps in making informed decisions when replacements or repairs are needed. This knowledge also aids in preventing damage caused by incorrect handling or installation.

How to Read the Parts Diagram

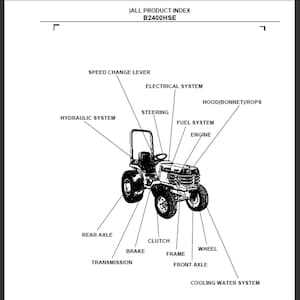

Interpreting visual guides for machine components can seem daunting at first, but once you understand the basics, it becomes a valuable tool for identifying and managing various parts. These illustrations serve as blueprints, offering a detailed view of how individual components interact within the machine. By learning how to decode these visuals, you can navigate maintenance tasks with ease and accuracy.

The key to reading these guides lies in understanding the symbols, numbers, and relationships shown in the images. Each part is represented with a unique identifier, making it easier to locate it within the system. Often, accompanying labels or codes give further insight into the part’s specifications, helping you match the correct replacement or understand its function in the system.

Common Replacement Parts for Kubota M7060

Over time, certain components within any heavy-duty machine are more likely to wear out or fail due to regular use. Recognizing these components early can prevent breakdowns and extend the life of your equipment. Commonly replaced elements are critical for ensuring that the machinery continues to operate smoothly and efficiently.

Engine and Transmission Components

The engine and transmission are central to the performance of the machine, and many parts within these systems require regular replacement. Components such as filters, belts, and seals often experience wear and should be replaced periodically to maintain proper functionality. Keeping these elements in top condition prevents costly engine damage and ensures the machine operates at peak efficiency.

Hydraulic System Parts

Parts related to the hydraulic system, such as pumps, hoses, and valves, are also frequently replaced. These components are essential for powering various attachments and functions, and any malfunction can disrupt the machine’s capabilities. Regular inspection and timely replacement of these elements are vital for avoiding system failures and ensuring reliable operation during heavy-duty tasks.