In any heavy machinery, knowing how each individual component works together is crucial for ensuring smooth operation and longevity. Proper maintenance and timely repairs are often facilitated by detailed breakdowns of the machine’s structure, allowing operators and technicians to quickly locate any issues.

By familiarizing oneself with the essential elements that make up the machinery, it becomes easier to perform necessary upkeep and troubleshoot problems. This understanding also aids in sourcing the correct replacements, ultimately reducing downtime and improving performance.

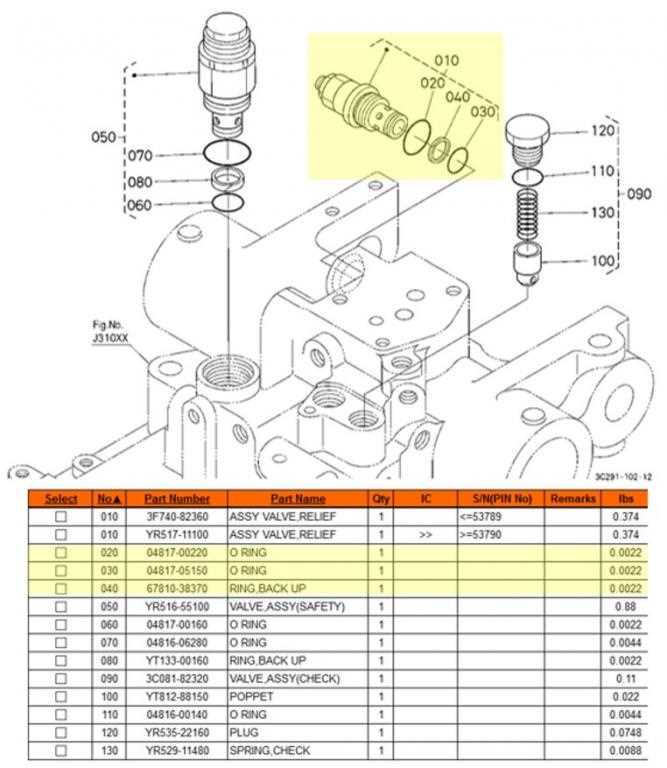

Accurate representations of the various components are invaluable tools for anyone working with mechanical equipment. These visual guides offer a clear, organized approach to understanding the layout and function of each part, supporting efficient maintenance and repair processes.

Understanding the Components of the Machine

Every complex machine consists of a variety of elements that work together to ensure efficient operation. These components range from basic structural elements to intricate mechanical systems, each playing a critical role in the overall functionality. Recognizing the purpose and relationship of each part helps in troubleshooting, repairing, and maintaining the equipment.

Key Systems and Their Roles

The machinery features several systems that function in tandem to power and control its operations. These systems, from the engine to the hydraulic mechanisms, are essential for ensuring that the machine performs optimally under various conditions. Understanding how these systems interact helps operators address any performance issues quickly.

Locating and Identifying Components

Knowing where each part is located within the machine is vital for performing routine maintenance and diagnosing problems. Accurate identification allows technicians to focus on specific areas, ensuring a quicker and more efficient repair process. This knowledge also aids in sourcing the correct replacements, minimizing downtime.

Key Components in the Machine

A heavy-duty machine is made up of several crucial systems and components that are responsible for its performance. Each element has a specific function, contributing to the overall efficiency and power. Understanding these key components allows for proper maintenance and quick resolution of any operational issues.

Engine and Power Transmission

The engine is the heart of the equipment, providing the necessary power for operation. It works in conjunction with the transmission system, which transfers energy to the wheels or other moving parts. Maintaining these elements is essential for smooth performance and preventing costly repairs.

Hydraulic and Steering Systems

The hydraulic system plays a significant role in controlling various functions, from lifting to driving. The steering mechanism, which is closely tied to the hydraulic system, ensures precise movement and maneuverability. Both systems must be regularly checked to ensure proper fluid levels and avoid malfunction.

How to Use the Visual Guide Effectively

A well-structured visual guide can be an invaluable resource when working with complex machinery. It provides a clear overview of the key components, allowing users to locate and identify different elements quickly. When used correctly, it helps streamline the maintenance process and reduces the time spent on repairs.

To make the most of such a guide, it is essential to first familiarize yourself with the overall layout. Start by understanding the sections and categories, which often group related elements together. This will enable you to quickly pinpoint the part you need without confusion.

Additionally, always pay attention to any labels or numbers on the guide, as they correspond to the exact location and identification of the components. Cross-referencing these with the physical machine ensures that you are working with the correct area and part, avoiding mistakes and improving efficiency during repairs.