In any complex machinery, knowing the specific roles of each individual part is essential for optimal operation and efficient repair. This section focuses on the intricate layout and connection of critical elements within these robust systems. Understanding how different components interact can significantly improve both maintenance strategies and troubleshooting efforts.

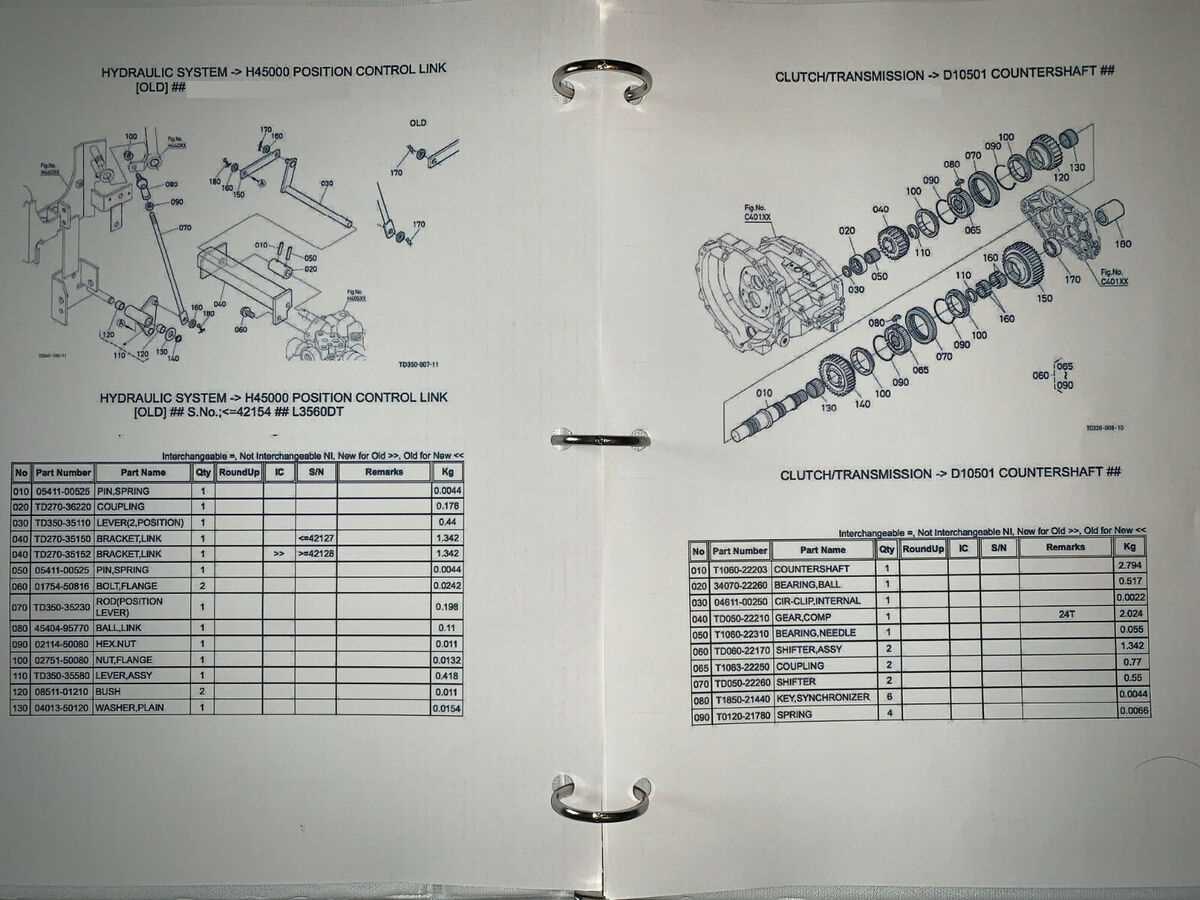

Every machine consists of various interconnected sections, each serving a unique function. By mapping these sections, operators and technicians can pinpoint issues, carry out precise repairs, and prevent costly downtimes. Whether you’re dealing with a mechanical failure or performing routine maintenance, grasping the full structure of the system is indispensable.

Effective management of mechanical systems requires a comprehensive understanding of how every piece fits together. This guide provides clarity on the different segments, helping to optimize the machine’s lifespan and enhance performance over time.

Understanding the Key Components of the Machine

Heavy machinery consists of numerous interconnected elements that work in harmony to ensure smooth operation. Each segment serves a specific function, contributing to the overall performance and durability of the equipment. Grasping how these parts interact is vital for those responsible for the upkeep and efficient functioning of the system.

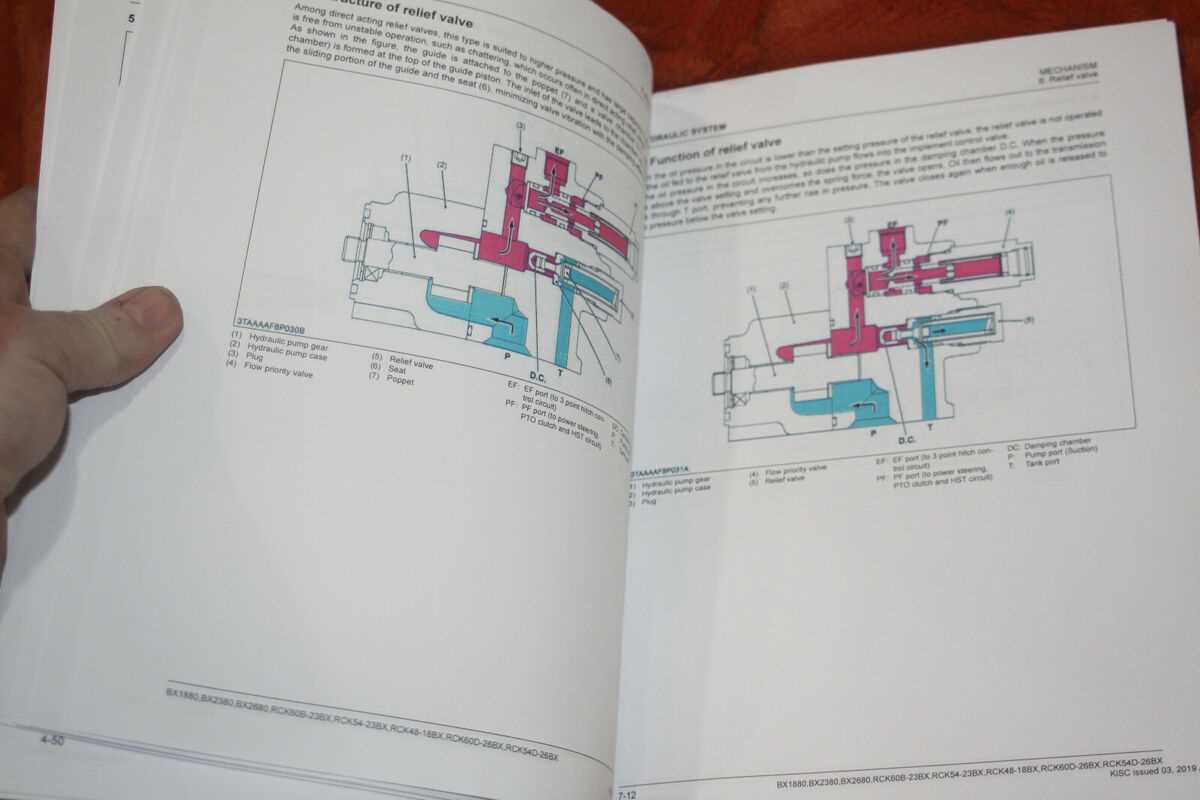

From the engine to the hydraulic system, every section plays an essential role in enabling the machine to perform its intended tasks. Identifying the layout and flow of energy between these components aids in diagnosing issues quickly and accurately. A well-structured understanding of the mechanical components ensures that any adjustments or repairs are made effectively.

Properly maintaining these elements not only extends the life of the machinery but also improves its efficiency, reducing operational costs and preventing breakdowns. By familiarizing oneself with the key parts and their functions, operators can perform better routine checks and address any potential concerns before they become serious problems.

Key Parts and Their Functions in Detail

The efficiency of a complex machine relies on the functionality of its individual sections. Each component plays a vital role in ensuring smooth operations and overall performance. Understanding the specific tasks of each part allows for better maintenance and troubleshooting.

The engine serves as the heart of the system, converting energy into mechanical motion to power the machine. It is essential for driving other components and ensuring the system runs effectively. Hydraulic systems, on the other hand, are responsible for the movement of heavy loads and are critical for handling various tasks such as lifting, pushing, and pulling. They rely on fluid power to function, making their design and operation crucial for the machinery’s capabilities.

The transmission is another significant section, transferring power from the engine to the wheels or tracks. Its job is to regulate the speed and direction of the machine. Electrical systems support all automated functions, including sensors and control units, ensuring the machine’s behavior is managed efficiently and accurately.

Each of these components needs to be properly maintained to avoid mechanical failures. Regular checks and proper lubrication ensure that these systems continue to function without issues, prolonging the lifespan of the machinery and enhancing its reliability on the job site.

How the Blueprint Aids in Maintenance

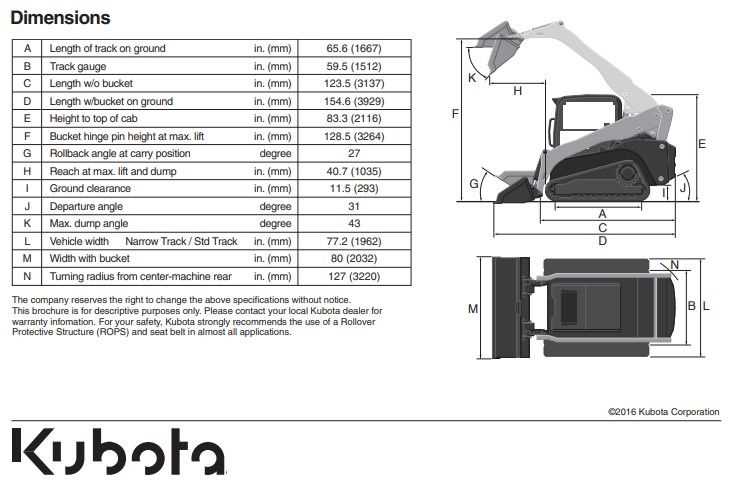

A detailed schematic provides valuable insight into the structure and interconnection of various machine components. By offering a visual representation, it helps technicians understand the layout of the system, enabling them to identify specific areas that require attention. This is particularly useful when performing diagnostic checks or troubleshooting complex issues.

With a clear map of the mechanical elements, maintenance becomes more efficient. Technicians can quickly pinpoint the location of a malfunctioning part, reducing the time spent searching for problems. Additionally, knowing the precise connections between sections ensures that repairs are done correctly, avoiding unnecessary disassembly and minimizing the risk of damage.

The blueprint also supports preventive maintenance by providing guidelines for regular inspections. By referring to the layout, operators can check key areas on schedule, ensuring that each section is in optimal condition. This proactive approach helps extend the lifespan of the equipment and reduces the likelihood of unexpected breakdowns during operation.