Maintaining agricultural equipment requires a clear understanding of its individual components and how they work together. Knowing the layout of the various sections can help you with both repairs and upkeep. This section explores how identifying specific elements within your tractor can improve overall performance and longevity.

By studying the layout and structure of the machine, you can easily pinpoint issues before they escalate. Whether it’s for routine maintenance or troubleshooting a problem, being familiar with how each piece interacts can save both time and money.

Efficient maintenance is key to keeping your equipment running smoothly. In this guide, we’ll walk you through how to interpret the schematics for quick identification of necessary parts, helping you ensure that your machinery stays in top condition for years to come.

Kubota T1560 Component Breakdown

Understanding the structure of your machinery is essential for effective operation and maintenance. By familiarizing yourself with the different sections and elements that make up the equipment, you can troubleshoot issues more efficiently and ensure that everything functions as intended. The following section provides a breakdown of the key components that are crucial for the smooth operation of your machine.

Main Assembly and Function

The main structure of the equipment consists of several essential components that work in unison to power the machine. These elements include the engine, transmission system, steering mechanism, and hydraulic system, all of which play significant roles in the machine’s performance. By understanding the function of each part, you can identify potential areas of concern and perform necessary checks.

Key Mechanical Components

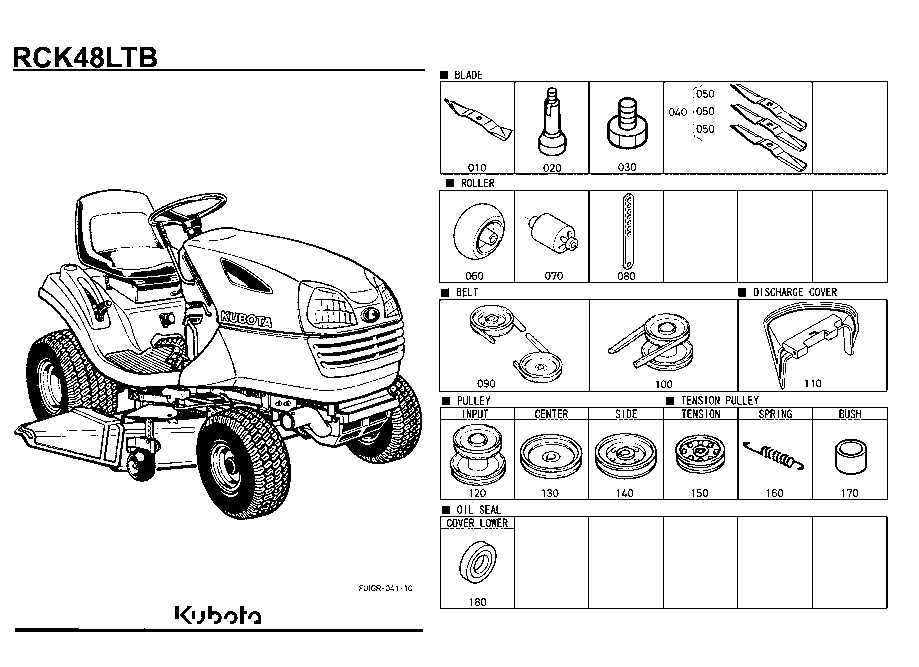

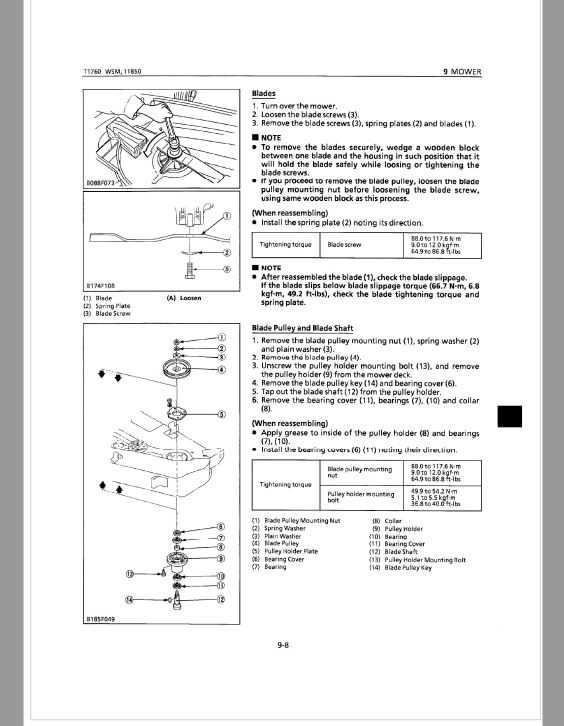

Within the system, there are various mechanical components that require regular attention, such as belts, pulleys, gears, and shafts. These parts must be maintained properly to ensure smooth operations, as wear and tear can impact the overall performance. Identifying the correct parts and knowing their functions will make it easier to perform repairs when needed.

| Component | Function |

|---|---|

| Engine | Provides the power necessary for operation |

| Transmission | Transfers power from the engine to the wheels |

| Steering | Enables maneuverability and direction control |

| Hydraulic System | Operates the lifting and lowering mechanisms |

By breaking down each of these systems and components, you gain a clearer understanding of how your machinery functions as a whole. This knowledge is crucial for both routine maintenance and identifying potential issues early, ensuring your equipment operates efficiently over time.

Understanding the Tractor Assembly Parts

To effectively operate and maintain your agricultural machinery, it is crucial to understand the structure and layout of its various systems. Each section plays a distinct role in the overall functioning, ensuring that the equipment performs optimally. This section delves into the major elements that make up the assembly and how they interact to provide maximum efficiency during use.

The core structure typically includes the power unit, the transmission system, the steering mechanism, and hydraulic components, all of which are integral to the machine’s performance. By gaining an understanding of each component, you can identify problems early on and take proactive measures to prevent breakdowns.

In this section, we will examine the different sections of the equipment, providing insights into their purpose and functionality. Familiarity with these components will enable you to make informed decisions when it comes to maintenance and repairs, ensuring your machinery operates at its best throughout its lifespan.

Key Components of Kubota T1560

For optimal functionality, understanding the key components of your machine is essential. Each element plays a specific role in ensuring smooth operation and durability. Knowing the core sections allows for better troubleshooting, effective maintenance, and longer service life.

The most critical systems of the equipment include the engine, transmission, and hydraulic functions. Proper maintenance and care of these components are necessary to maintain consistent performance. Below are the main components that need attention for proper operation:

- Engine – The heart of the machine, providing the power needed for various operations.

- Transmission – Transfers power from the engine to the wheels, enabling movement and operation.

- Steering System – Provides maneuverability, allowing the operator to guide the machine efficiently.

- Hydraulic System – Manages lifting and lowering functions, essential for handling attachments and accessories.

Maintaining each of these components ensures smooth operation, helping you maximize the machine’s lifespan and minimize costly repairs. Regular checks on the key elements outlined above will ensure that your equipment runs at peak efficiency for years to come.

What to Look for in the Diagram

When examining a visual representation of your machine’s components, it’s essential to know what to focus on for effective maintenance and repairs. A well-detailed schematic can guide you in identifying and understanding the function of each part, making it easier to spot issues before they become major problems.

Key elements to pay attention to include:

- Component Labels – Clear markings that identify each element in the system, helping you understand the function of each part.

- Connection Points – These show how different sections of the machinery are linked, ensuring proper functioning when in operation.

- Exploded Views – Visuals that break down the assembly into individual components, making it easier to identify where specific parts belong.

- Critical Areas – Sections prone to wear and tear, such as belts or seals, that require regular attention to avoid malfunction.

By focusing on these aspects, you can gain a better understanding of how the various components interact and ensure that the equipment remains in good working order over time. Regular review of the schematic is an essential step in proper maintenance and troubleshooting.

Maintenance Tips for Kubota T1560

Regular maintenance is essential to keep your machinery running smoothly and efficiently. By following a structured approach to upkeep, you can prevent unexpected failures and extend the lifespan of your equipment. This section provides important tips on maintaining your machine to ensure it remains in optimal condition.

Regular Inspections

Performing regular checks on the key systems is vital for early detection of potential issues. Focus on the engine, transmission, and hydraulic systems, as these are integral to the machine’s overall function. Ensure that there are no leaks, unusual noises, or signs of wear, and always clean the filters and air intakes to ensure maximum performance.

Lubrication and Fluid Levels

Proper lubrication of moving parts prevents unnecessary friction and wear, ensuring smoother operation. Regularly check and maintain the proper fluid levels for the engine, hydraulic system, and transmission. Always use the recommended oils and fluids, as this will help maintain the efficiency and longevity of the equipment.

By following these maintenance practices, you can ensure your machinery performs at its best for years, reducing the likelihood of costly repairs and downtime. Regular care is key to keeping your equipment in top condition and ensuring its continued productivity.