Maintaining machinery is crucial for ensuring its longevity and performance. A clear understanding of each element that makes up the system can significantly aid in proper upkeep and repairs. When working with complex equipment, having a visual representation of its internal structure can be incredibly helpful for both routine maintenance and troubleshooting.

Identifying individual components and understanding how they work together is the first step toward effective management. Recognizing the role of each part allows for a more informed approach when it comes to replacing or repairing parts that might wear out over time. Whether you are a professional mechanic or a DIY enthusiast, having access to a detailed outline of the machine’s structure can save you time and effort.

Moreover, knowing the proper names and functions of each piece enables easier communication with suppliers and technicians. This knowledge also ensures that you order the correct parts when needed. As you delve deeper into the system’s design, it becomes clear how interconnected everything is and how a small change in one area can affect the entire unit.

Understanding Kubota Z125E Components

Every machine is a carefully designed system made up of various interconnected elements, each playing a crucial role in ensuring smooth operation. Familiarity with these individual components helps improve the efficiency of maintenance and repairs. Recognizing how each part contributes to the overall performance can make a significant difference in diagnosing issues or upgrading the system.

Key Elements of the Equipment

One of the first things to understand is the distinction between the core functional units and their auxiliary components. The engine, transmission, and control system are the heart of the machine, while additional features such as the cooling, fuel, and exhaust systems support its overall function. Each of these systems relies on a network of smaller parts that work together in harmony to ensure smooth operation.

Efficient Maintenance Practices

Regular maintenance requires a solid understanding of how the various elements interact. Performing checks on essential systems such as the ignition, hydraulic, and steering can help identify early signs of wear and tear. By keeping track of which components need regular attention, operators can avoid costly breakdowns and ensure that the machine runs at its peak performance for years.

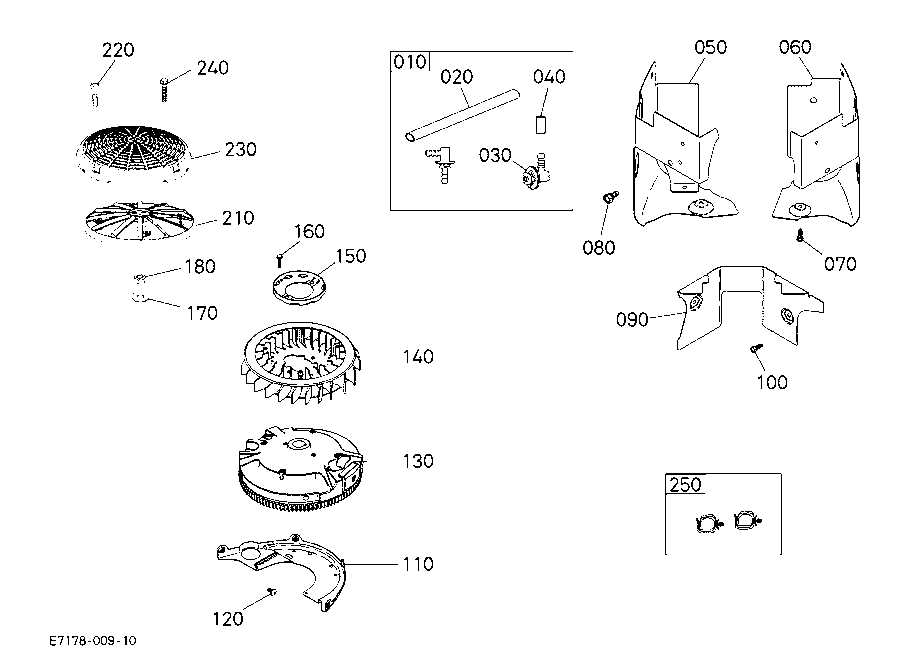

How to Read the Parts Diagram

Interpreting technical illustrations of machinery is an essential skill for anyone involved in equipment maintenance. These detailed visuals provide a comprehensive overview of how various components are arranged and connected within the system. Understanding how to read these representations can streamline the repair or assembly process, making it much easier to identify, replace, or adjust specific elements.

To effectively read these diagrams, it’s important to focus on the layout and numbering system. Each section will usually have corresponding labels or codes that help in identifying the individual components. By following these labels, one can trace the flow and function of the system. Recognizing common symbols and how they relate to real-world counterparts allows for quicker identification of what needs attention or replacement.

Another crucial aspect is understanding the scale and proportions. These diagrams are often drawn to scale, meaning the sizes of the parts are relative to each other. This makes it easier to visualize how parts fit together or how one component might impact the others. With some practice, reading these diagrams becomes an intuitive process that saves both time and effort during maintenance tasks.

Essential Parts for Kubota Z125E Maintenance

To ensure the smooth operation of any machine, certain components require regular inspection and maintenance. Focusing on the most critical elements can significantly improve the machine’s lifespan and reduce the risk of costly repairs. Identifying and understanding these core units is key to successful upkeep and performance.

Key Functional Components

The engine is at the core of any machine, and proper care of this vital component is essential for optimal performance. Regular checks on the fuel system, spark plugs, and air filters can prevent common issues such as poor starting or power loss. The transmission system, which includes the belts, pulleys, and gears, also needs frequent attention to ensure smooth operation and prevent wear over time.

Support Systems for Efficient Operation

Alongside the engine and transmission, other support systems such as the cooling and hydraulic systems are crucial for preventing overheating and ensuring smooth operation. The cooling system, consisting of the radiator, hoses, and coolant, must be monitored to avoid breakdowns. Similarly, the hydraulic system, including pumps and fluid levels, requires consistent monitoring to maintain pressure and efficiency.