When it comes to keeping your aerating equipment in optimal condition, knowing the layout and function of each individual component is essential. A clear understanding of how the various elements work together can help you perform more effective maintenance and troubleshoot issues quickly.

Every machine has its unique assembly, and familiarizing yourself with its structure allows for efficient repairs and adjustments. Whether you are replacing worn-out parts or just performing routine checks, understanding the system’s framework will ensure smoother operation and longer-lasting performance.

Thorough inspection and proper care of your equipment can prevent costly repairs. With the right knowledge, even complex issues become manageable, saving time and effort in the long run.

Understanding the Lawn Aerator Components

To ensure your lawn aerating machine functions efficiently, it’s important to grasp the arrangement and role of each key element within its structure. Knowing how the individual components interact can help you identify potential issues and maintain smooth operation over time.

The assembly includes various mechanical elements, each designed for a specific purpose, from propulsion to aeration. Recognizing these components and their functions allows you to troubleshoot effectively and make necessary adjustments for optimal performance.

Regular examination and care of these elements not only prolong the life of the equipment but also prevent common malfunctions. A clear understanding of the machinery’s framework ensures that maintenance tasks are carried out with precision, minimizing downtime and maximizing efficiency.

How to Read the Equipment Layout

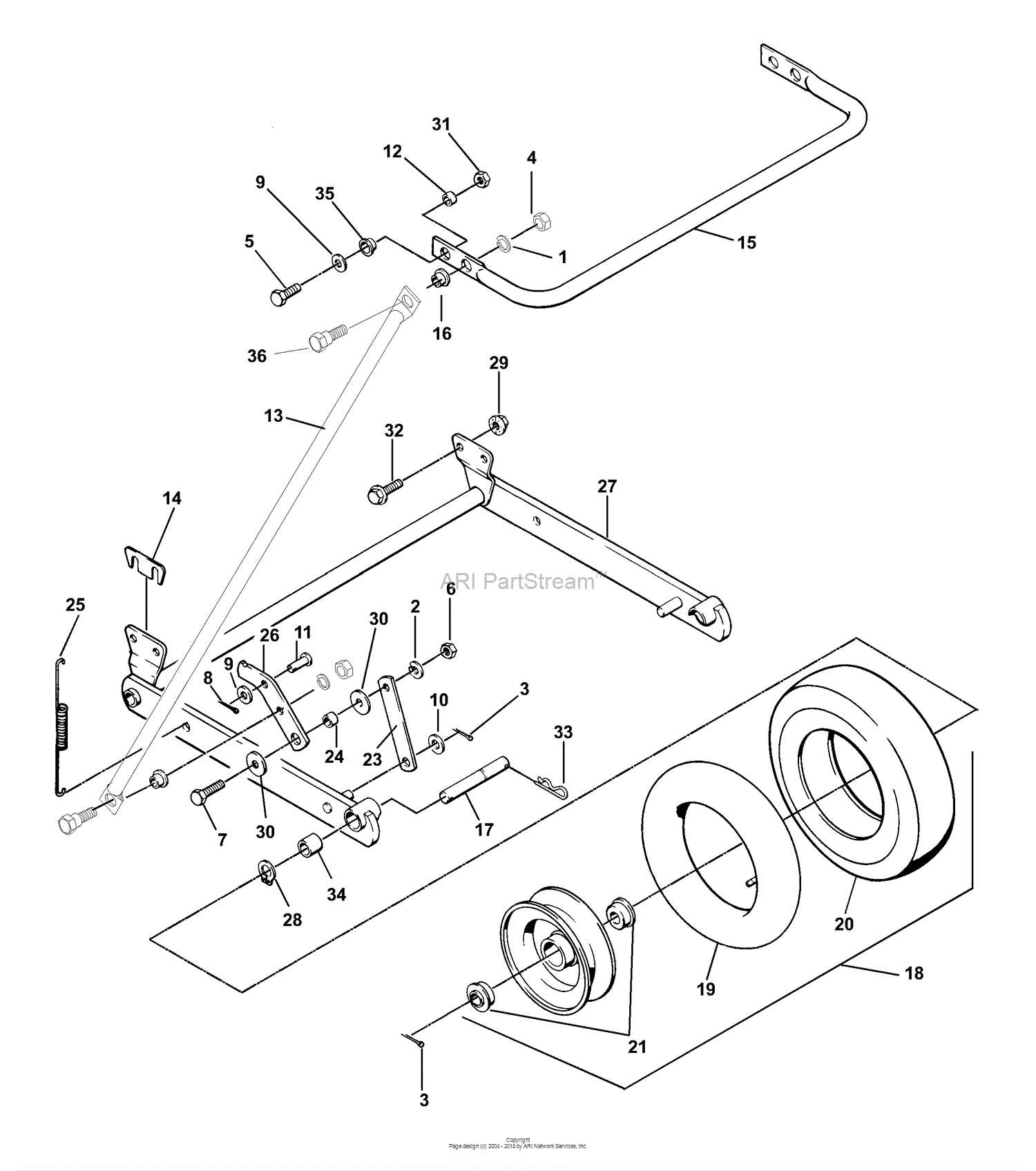

Understanding the layout of an aerator’s components is crucial for effective maintenance and repairs. By examining the visual representation of the machine, you can identify the location and function of each element, making it easier to troubleshoot and replace any malfunctioning parts.

Breaking Down the Visual Guide

The visual representation typically divides the machine into sections, each highlighting specific areas such as the engine, wheels, or aeration mechanism. This organized approach helps you focus on one section at a time, making it simpler to find the exact component you need to address.

Identifying Key Elements and Functions

Each labeled part or section in the visual guide corresponds to a particular function, such as the transmission or aeration tines. Understanding these labels allows you to quickly identify parts that require attention or replacement, ensuring that you perform tasks with precision.

Essential Maintenance Tips for Lawn Aerator

Proper maintenance is key to extending the life of your lawn care equipment and ensuring it operates at peak efficiency. Regular attention to the components will help avoid costly repairs and improve the overall performance of your machine.

Routine Inspections and Cleaning

Regularly inspect and clean the machine, focusing on areas that come in contact with soil or grass. This includes removing any dirt or debris that could cause blockages or impair movement. Keeping the engine area clean also helps prevent overheating and ensures smoother operation.

Lubrication and Component Checks

Lubricate moving parts regularly to reduce wear and tear. Check for any signs of rust or corrosion on key elements like shafts or bearings. Replacing worn components promptly will keep your aerator running smoothly and prevent further damage.