Every complex tool is made up of numerous components that work in harmony to achieve precise results. Knowing the arrangement and function of each element can significantly enhance your ability to troubleshoot, maintain, and optimize performance. By becoming familiar with the internal layout, you can gain a better understanding of how each part contributes to the overall function.

For those looking to improve their skills or address issues, a clear visual reference can be invaluable. This guide provides an overview of how to interpret the layout, offering insights into the individual elements and their interactions. Whether you’re performing routine maintenance or learning about advanced features, understanding these connections will empower you to get the most from your tool.

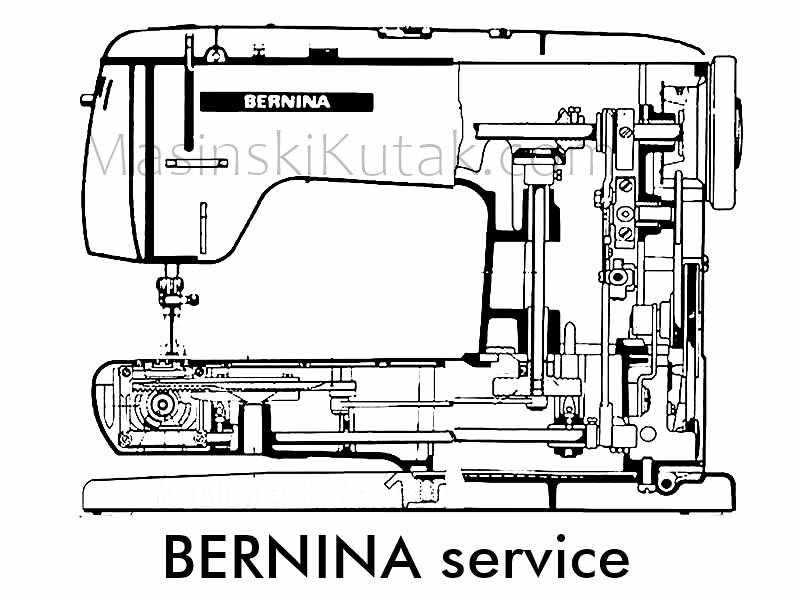

Understanding the Key Parts of Bernina Sewing Machine

Every intricate tool consists of a variety of essential components, each playing a vital role in ensuring smooth operation. The design of these elements is often crafted to maximize efficiency and accuracy, working together to deliver high-quality results. Understanding the functionality of each piece allows users to troubleshoot problems, perform maintenance, and fully appreciate how the tool operates as a whole.

The most crucial elements in this equipment include those responsible for controlling motion, adjusting tension, and guiding the material through the process. These components must interact seamlessly to guarantee the desired outcome. In addition to the core mechanical elements, there are also finer details that contribute to the ease of use and overall performance, such as the feed mechanism and the adjustment controls.

By familiarizing yourself with these key features, you’ll gain a clearer understanding of how everything fits together and how each function impacts your work. With this knowledge, you’re better prepared to maintain and optimize the tool for long-term use, avoiding unnecessary breakdowns and ensuring consistent quality in every project.

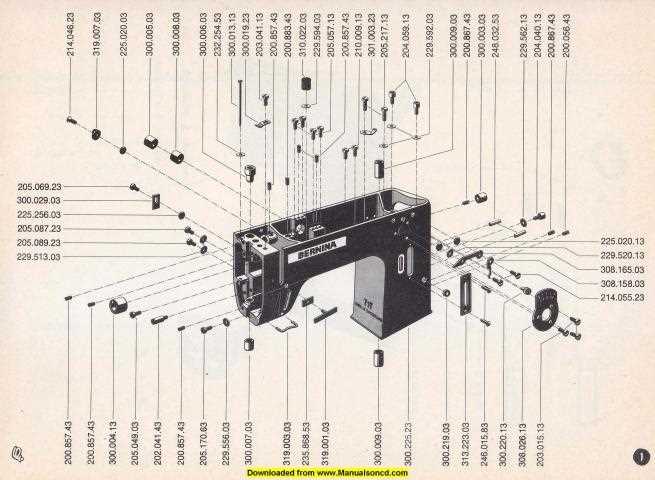

Detailed Breakdown of Bernina Components

Each tool is composed of several critical elements, each contributing to its overall functionality. To fully understand how the system operates, it’s important to break down the individual components that make up the structure. These components, while small on their own, are essential in ensuring smooth and effective performance.

Key elements include those that manage the movement of the material, control the precision of stitching, and regulate the tension. Additionally, there are smaller mechanisms that handle adjustments, offering flexibility and allowing users to fine-tune the device to suit different tasks. The intricate interaction between these pieces ensures that everything operates with precision, from the simplest to the most complex tasks.

A detailed exploration of these components not only helps users with troubleshooting but also provides insight into the design and innovation behind the tool. By understanding the role of each part, users are empowered to make informed decisions regarding maintenance and usage, ensuring optimal performance over time.

How to Use the Bernina Parts Diagram Effectively

To optimize the performance and lifespan of your tool, it’s essential to understand how to navigate and utilize the reference guide that illustrates the key elements within the device. This visual aid can be a valuable resource when addressing maintenance, troubleshooting, or upgrading your equipment. Knowing how to read and apply the guide correctly allows users to take full advantage of the system’s design and functionality.

Start by familiarizing yourself with the layout of the guide, paying attention to the labels and connections between various components. By identifying and understanding the role of each part, you can quickly pinpoint issues, perform repairs, and make adjustments as needed. This knowledge will also help in ensuring that each element is working together efficiently, contributing to smoother operation.

When using the reference, focus on matching the specific area of concern with the corresponding section in the guide. By cross-referencing the visual with the actual tool, you’ll gain a deeper understanding of how the internal systems interact. This approach helps you feel more confident in managing the tool’s upkeep and ensuring it continues to perform at its best.