In the world of body art, precision and reliability are crucial. To achieve exceptional results, understanding the individual components of your tools is essential. Each piece of equipment plays a unique role in ensuring smooth operation and quality output. By breaking down these elements, artists can gain a deeper appreciation of how everything works together.

Every tool in the kit serves a specific purpose, from controlling the flow of energy to maintaining steady movement. Recognizing the function of each component not only improves the performance but also helps in troubleshooting and maintenance. The intricate design and fine-tuned mechanisms allow artists to execute detailed designs with ease and consistency.

Mastering the use of these tools involves more than just knowing how to operate them. It requires understanding how each part interacts within the whole system, contributing to an optimal experience. Gaining insight into the setup allows for better customization and efficient problem-solving, ensuring that every session is as effective as possible.

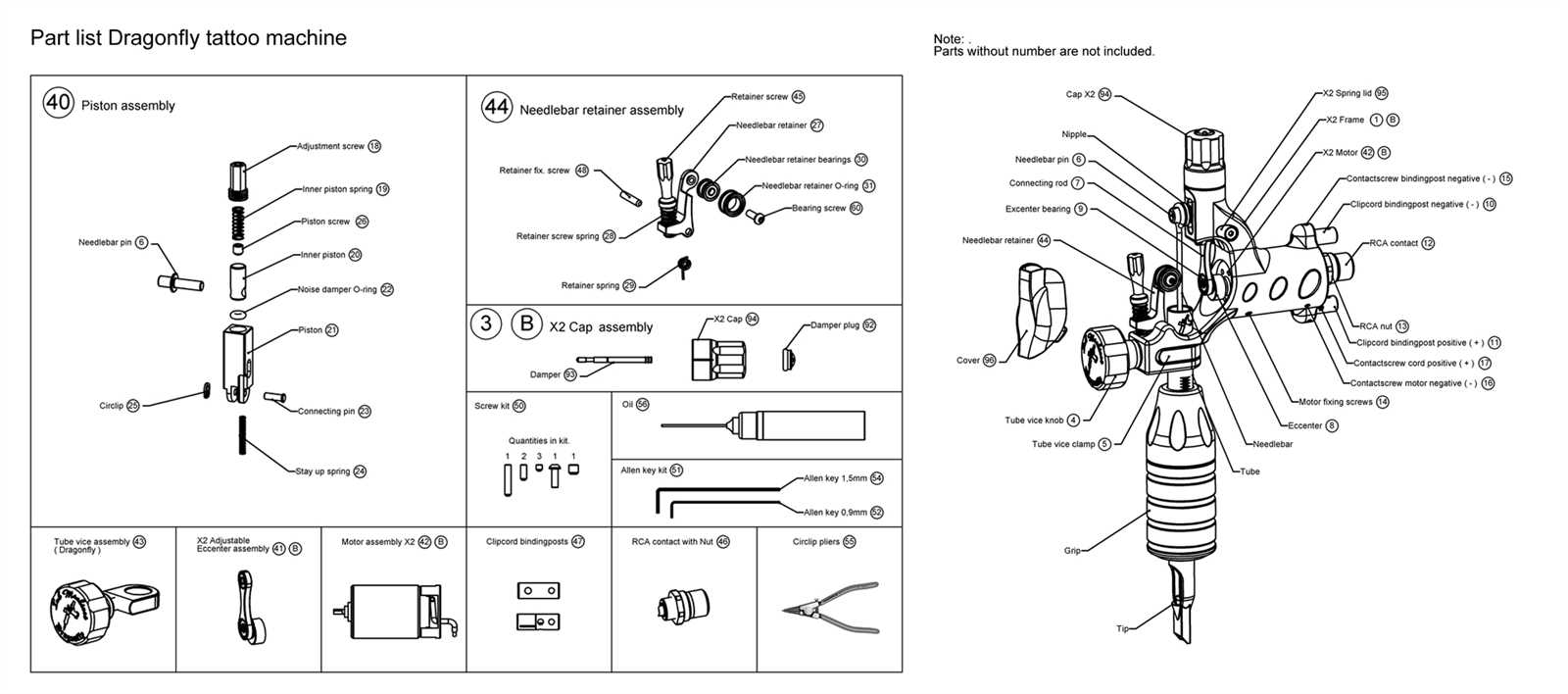

Understanding the Components of Rotary Machines

The success of any tool lies in its ability to function seamlessly through the collaboration of its internal elements. These elements are designed with precision, each serving a specific role that contributes to the overall effectiveness. Knowing how these components interact can greatly enhance the user experience, making the operation more efficient and reliable.

Every tool is made up of various integral components, from the driving mechanism to the control features. Each piece is carefully crafted to ensure smooth operation and deliver consistent results. A well-understood setup allows for customization based on the needs of the user, improving precision and comfort during use.

The energy transfer system, for instance, ensures that the movement is both steady and responsive, while the casing protects the internal elements, allowing for durability. By understanding the function of each segment, an operator can troubleshoot issues, make informed adjustments, and optimize their workflow.

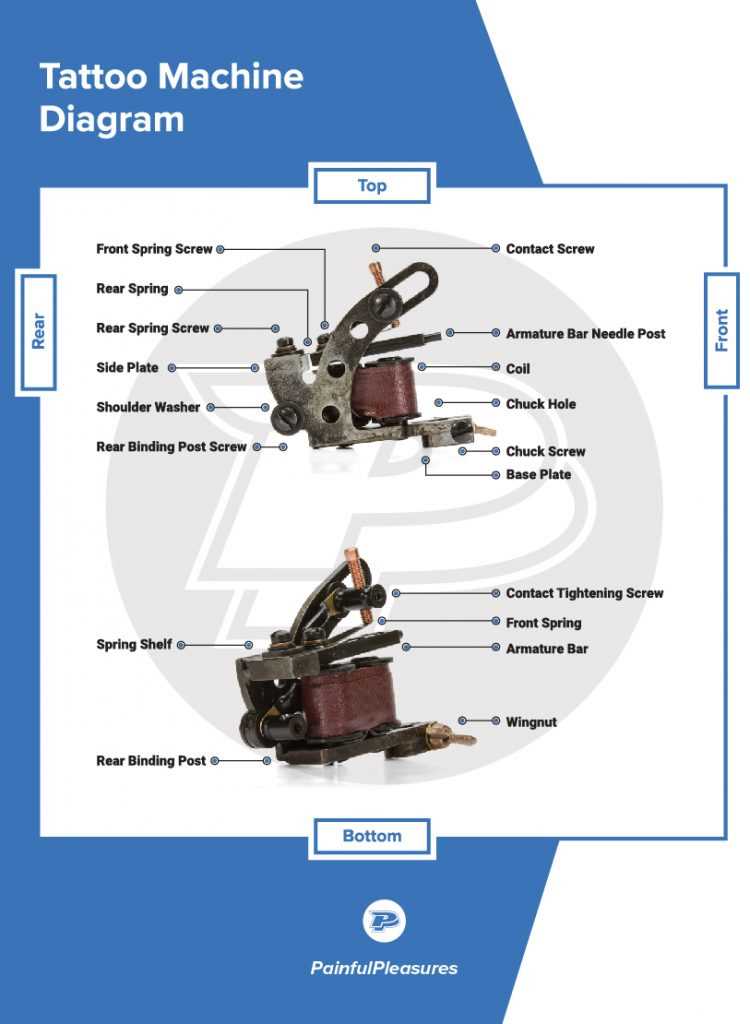

Key Parts and Their Functions Explained

Understanding the key components of any precision tool is crucial to maximizing its performance. Each individual element plays a unique role in ensuring smooth operation and reliability. Whether it’s the driving mechanism or the power system, every part has a specific function that contributes to the overall effectiveness.

Power Source and Energy Transfer

The power system is responsible for converting energy into movement, providing the necessary force for the tool to function efficiently. The transfer mechanism ensures that this energy reaches the moving parts, allowing them to perform precise tasks with consistent results. A well-maintained power source guarantees that the operation remains steady and uninterrupted.

Control Mechanisms and Adjustments

Control systems, including adjustments for speed and intensity, provide the user with the ability to fine-tune performance based on the task at hand. These components are designed for precision, offering flexibility to accommodate various techniques. Proper adjustment and maintenance of these elements are key to achieving desired outcomes and ensuring smooth functionality over time.

How the Rotary Tattoo Machine Works

The operation of these tools relies on a series of coordinated movements that generate the necessary motion to perform precise tasks. At its core, it uses a consistent force to drive a moving element, which in turn creates the motion required for intricate work. This process ensures accuracy and smooth performance during each session.

The energy generated by the power source is transferred through the internal components, where it is harnessed to produce the desired action. The moving element, typically a small oscillating part, creates rapid back-and-forth motions, which are essential for delivering the desired effects. The flexibility of these systems allows for fine adjustments in speed and intensity, providing complete control over the process.

By understanding the way these components interact, users can ensure that the tool operates at peak efficiency, delivering consistent results with every use. Proper maintenance and adjustment are key to sustaining high performance and preventing issues that could disrupt the workflow.