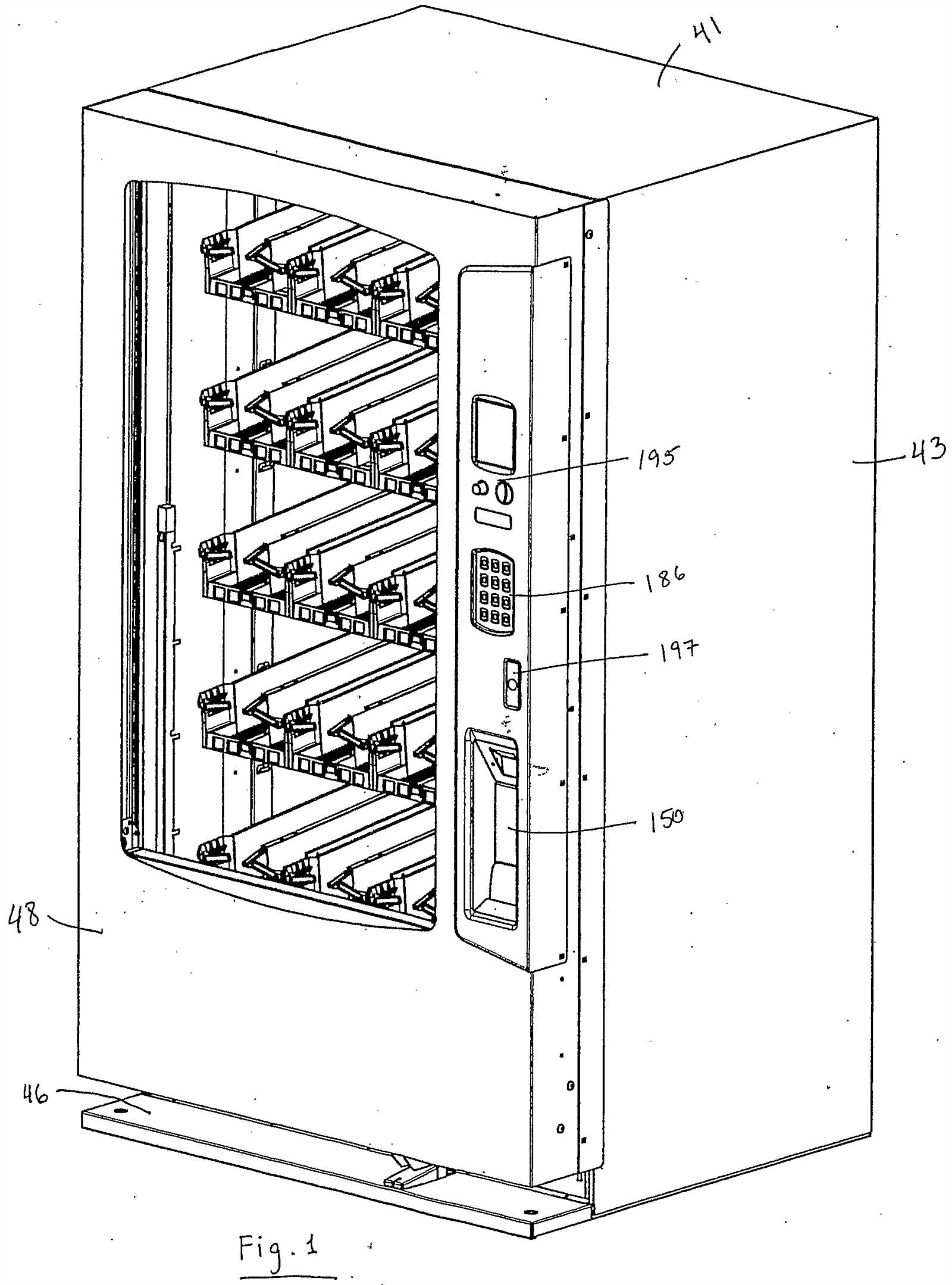

For anyone involved in the maintenance or operation of beverage dispensers, a clear understanding of their internal structure is essential. Knowing how the different elements interact allows for smoother troubleshooting and more effective repairs.

Each device consists of several crucial elements that ensure the smooth flow and delivery of drinks. From the refrigeration system to the dispensing mechanism, each component plays a vital role in the overall function.

By familiarizing yourself with the inner workings, you can avoid common malfunctions and identify issues before they become major problems. Proper knowledge of these systems is not only important for repair professionals but also for operators who aim to maintain high efficiency.

Key Components of a Beverage Dispenser

The functionality of any beverage dispensing system relies on several crucial elements working together seamlessly. Understanding how these components function and interact is vital for effective troubleshooting and optimal operation.

Refrigeration and Cooling System

The cooling system plays a central role in maintaining the temperature of the beverage. It works by circulating coolant to keep the liquid at the desired chill. This system helps to preserve the quality of the drink and ensures it is served at the correct temperature. A malfunction in this area can result in inefficient cooling or even spoilage.

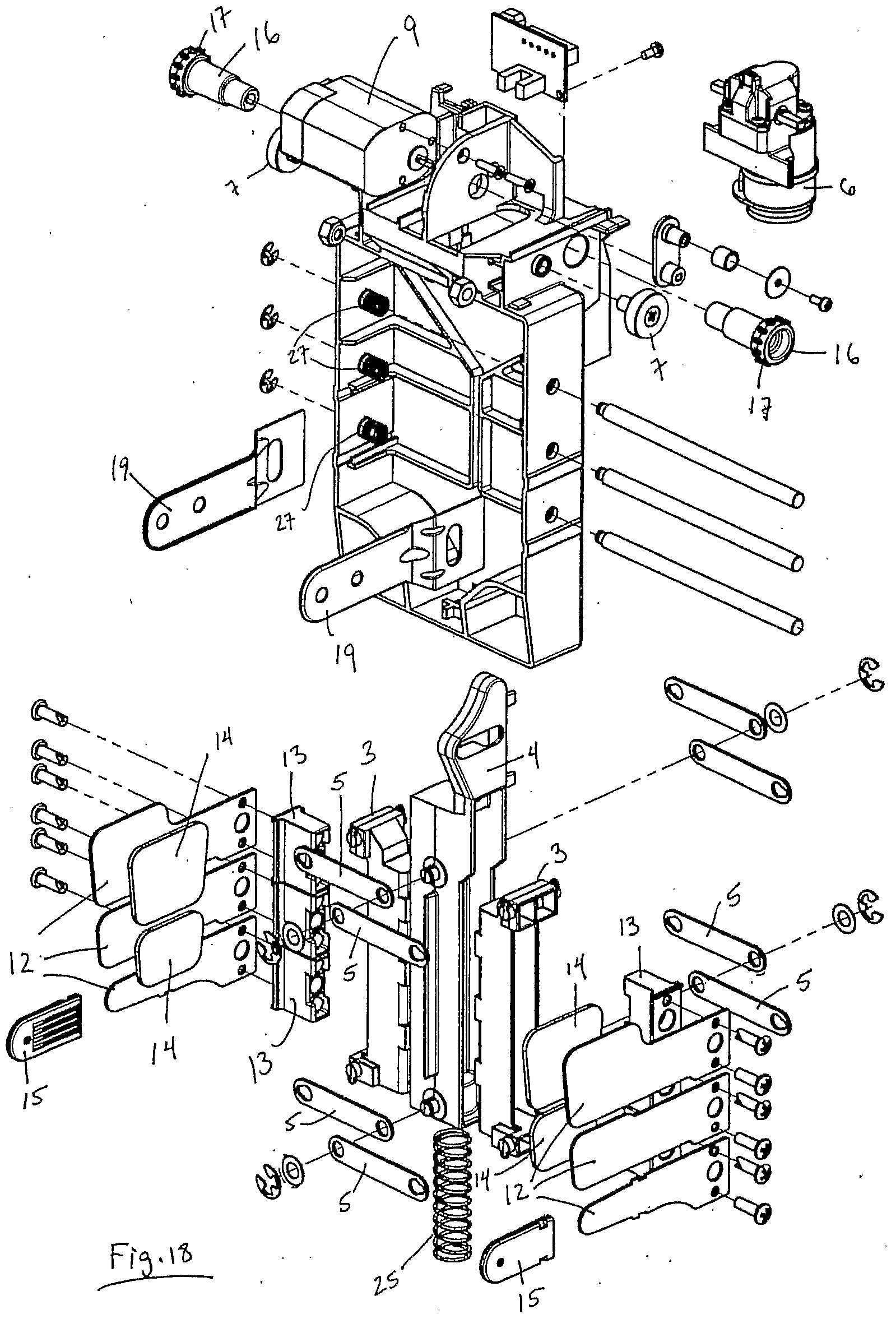

Dispensing Mechanism and Valves

The dispensing mechanism controls the flow of the drink into the cup. It uses a combination of valves, pumps, and tubing to direct the liquid precisely when the user presses the button. These systems are critical for accuracy and speed, ensuring that the right amount of liquid is delivered without leakage. Maintaining these components is essential for smooth service and minimal waste.

How a Beverage Dispenser Works Internally

Understanding the internal workings of a beverage dispensing unit is essential for anyone aiming to ensure its proper functionality. These systems are designed to efficiently deliver drinks through a combination of mechanical, electrical, and cooling components that interact seamlessly.

Cooling and Beverage Storage

The cooling unit is responsible for chilling the liquid to the correct temperature. This is achieved by circulating a refrigerant throughout the system, which absorbs heat and keeps the beverage at an optimal level for consumption. The liquid is stored in a refrigerated compartment, ensuring it remains cool until it is ready to be dispensed.

Liquid Dispensing and Control

The dispensing process begins when the user activates the controls, which triggers a valve to open. This valve, connected to the liquid reservoir, allows the beverage to flow into the dispensing tube. The flow rate is carefully regulated by the system to ensure that the correct amount is delivered each time. Additionally, a carbonation unit may be involved to add fizz to the drink, controlled by sensors that monitor pressure and carbonation levels.

Common Issues and Fixes for Beverage Dispensers

Despite their durability, beverage dispensers can experience a range of problems over time. Recognizing and addressing these issues early can help prevent long-term damage and ensure the system operates smoothly. Below are some of the most common problems and their solutions.

Overheating and Cooling Issues

If the cooling system is not functioning properly, the beverage may not stay chilled. This could be due to a malfunctioning compressor or a refrigerant leak. Checking the condenser coils and ensuring they are clean can help restore cooling efficiency. If the issue persists, it may be necessary to replace the compressor or repair the leak.

Clogging and Flow Problems

Clogs in the dispensing tubing can cause irregular flow or complete blockage. These issues often arise from debris or syrup buildup inside the system. Regular cleaning and maintenance of the tubing can prevent such problems. If the issue is severe, replacing the affected tubing may be necessary.