When dealing with any equipment, having a clear understanding of its internal structure is crucial for effective troubleshooting and maintenance. Proper knowledge of the various elements helps identify potential issues and ensures smooth operation over time. Whether you’re a professional technician or a DIY enthusiast, understanding how each part functions is essential for success.

Every device consists of multiple interconnected components, each playing a vital role in overall performance. By studying detailed visual representations, one can easily spot malfunctioning parts and quickly address them. Having access to accurate reference materials simplifies the repair process, saving time and reducing the risk of further damage.

In this section, we will explore the layout and features of these key elements, providing a better understanding of their interactions. With this knowledge, you’ll be better equipped to maintain your equipment efficiently, ensuring optimal functionality for an extended period.

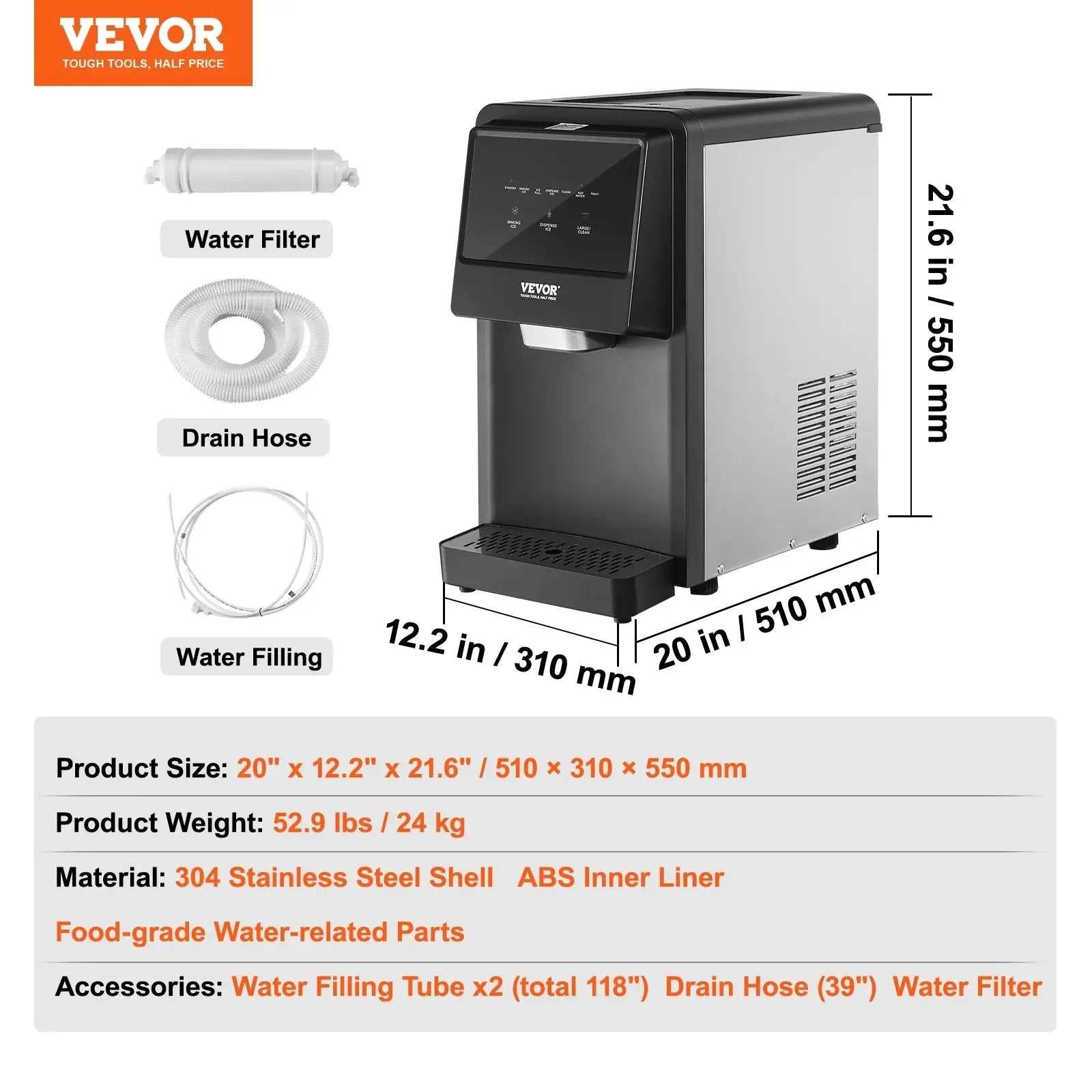

Understanding Vevor Ice Machine Components

To ensure efficient operation and longevity, it’s essential to recognize the primary elements of any cooling device. Each individual piece plays a significant role in how the overall system functions. Gaining a clear understanding of these components allows for better management, faster diagnosis of issues, and more effective troubleshooting when something goes wrong.

Many cooling systems consist of an array of parts that work together harmoniously. Each section, from the internal hardware to the exterior mechanisms, is designed to perform a specific task. Recognizing these different elements and how they interact can significantly improve your ability to maintain the equipment or repair it when necessary.

By familiarizing yourself with the layout of these critical components, you’ll be able to identify problems with greater precision and address them in a timely manner. Whether it’s examining the flow of water or checking the condition of a cooling unit, having a basic understanding of the system’s core elements ensures that you’re prepared for any situation.

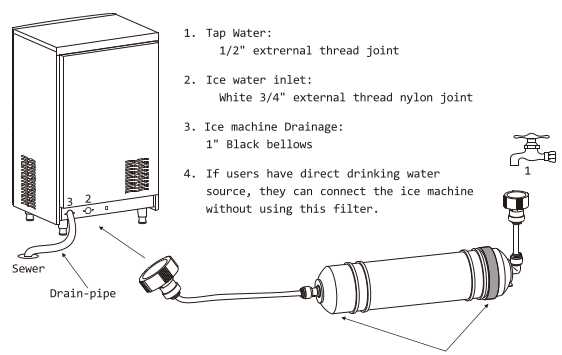

How to Read Vevor Ice Machine Diagrams

Understanding technical illustrations is an essential skill for anyone working with complex systems. These visuals provide a clear representation of how each element interacts and operates within the entire setup. Learning how to read these diagrams can help identify issues quickly and ensure that repairs are carried out effectively.

Identifying Key Elements

The first step in interpreting these illustrations is to recognize the various components shown. Each part is typically labeled with either a number or a letter, corresponding to specific instructions or functions. Focus on these identifiers to understand the role of each section and how it fits into the overall system.

Understanding Connections and Flow

Once the individual parts are identified, the next task is to follow the connections between them. Most diagrams will display lines or arrows indicating the flow of water, electricity, or other critical processes. Tracking these paths helps clarify how the system operates and where problems may arise, allowing you to troubleshoot with more accuracy.

Common Vevor Ice Machine Part Issues

Even the most reliable equipment can experience malfunctions over time. Recognizing the most frequent problems with key components can help address issues swiftly and prevent more significant damage. Whether it’s wear and tear or improper usage, identifying common faults allows for a quicker diagnosis and a smoother repair process.

Electrical Failures

One of the most common issues is related to electrical connections. Faulty wiring, power surges, or damaged electrical components can disrupt normal operations. Ensuring that all connections are secure and the electrical system is properly maintained is crucial to prevent breakdowns.

Water Flow Problems

Another frequent problem arises when water flow is blocked or restricted. This could be due to clogged filters, blocked hoses, or worn-out seals. Without proper water flow, the system may not function efficiently or could even fail completely. Regular maintenance and inspection of the water channels can help avoid these issues.