Knowing the various elements that make up a wood cutting tool is essential for proper maintenance and efficient use. Each component plays a critical role in ensuring the tool operates smoothly and safely. Understanding these individual parts allows you to troubleshoot problems and perform repairs with ease.

In this section, we will explore the different sections of the cutting mechanism, offering a visual representation of how the parts work together. By identifying each element, you’ll gain a deeper appreciation for the machinery’s design and functionality.

With the right knowledge, it becomes easier to maintain the tool, address common issues, and extend its lifespan. Proper upkeep can make a significant difference in performance and efficiency over time, leading to more productive work sessions.

Understanding the Components of the Wood Cutting Tool

Every tool designed for cutting and processing wood consists of various interconnected sections, each performing a specific function. Understanding these components helps users ensure that the equipment works efficiently and safely. Recognizing the importance of each element allows for better maintenance and troubleshooting.

The design of these tools relies on several key components that work together to facilitate the cutting process. From the central frame to the hydraulic system, each part has a distinct role in converting energy into effective force for splitting logs. Familiarizing yourself with these elements is crucial for anyone aiming to extend the tool’s lifespan and improve its performance.

Proper care and understanding of each section not only prevent potential malfunctions but also optimize the overall function of the equipment. By maintaining the key components, users can achieve consistent results and avoid unnecessary repairs.

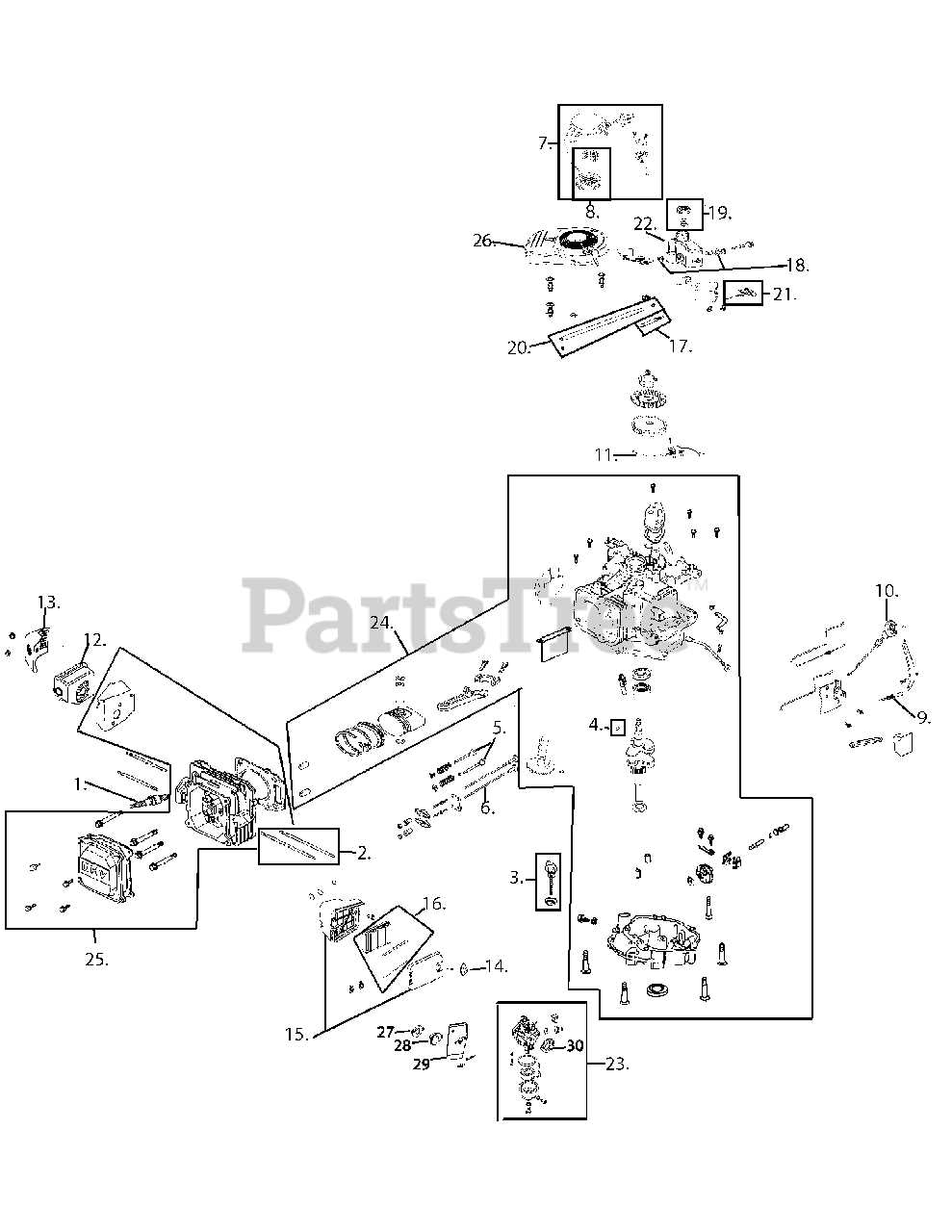

How to Identify Each Part in the Diagram

To effectively manage and repair a wood processing tool, it’s essential to recognize each individual element within its design. The various sections and components are usually labeled, and understanding these labels is key to identifying the role of each part. By studying the layout, you can easily distinguish the function of each section and how they work together to ensure proper operation.

Recognizing Key Components

Start by familiarizing yourself with the primary structure of the equipment. The central frame, hydraulic components, and moving parts are often the most critical. By carefully studying their shapes and placement, you can quickly learn their specific functions. The diagram will usually highlight these prominent sections, making identification more straightforward.

Focusing on Smaller Elements

Once the larger parts are identified, move on to the smaller elements such as fasteners, connectors, and safety features. These details are often overlooked but are just as crucial for the equipment’s performance. Recognizing these smaller components ensures that you don’t miss essential maintenance or replacement needs.

Common Maintenance Tips for Wood Cutting Tools

Regular maintenance is vital to keep your wood processing equipment functioning efficiently and prolong its lifespan. By performing simple checks and applying basic care, you can avoid costly repairs and ensure the tool operates at its best. A few preventive measures will help you stay ahead of potential issues and maintain smooth performance throughout its use.

Routine Inspections and Cleaning

One of the most important maintenance tasks is keeping the tool clean and free from debris. Inspect the tool after each use to remove any dirt or wood fragments that could interfere with moving parts. Regular cleaning prevents buildup that could lead to malfunctions, and also allows for early detection of wear and tear.

Lubrication and Fluid Checks

Hydraulic components and moving parts require consistent lubrication to minimize friction and ensure smooth operation. Check oil levels regularly and replace fluids as necessary. Additionally, be sure to lubricate any exposed metal surfaces to prevent rust and damage, especially if the tool is frequently exposed to the elements.