When working with electrical devices, it’s essential to have a clear understanding of how they function internally. A thorough knowledge of the internal components and their roles ensures efficient operation and easier troubleshooting. Each element of a system plays a crucial role in its overall performance, and recognizing how they interact is key to achieving optimal results.

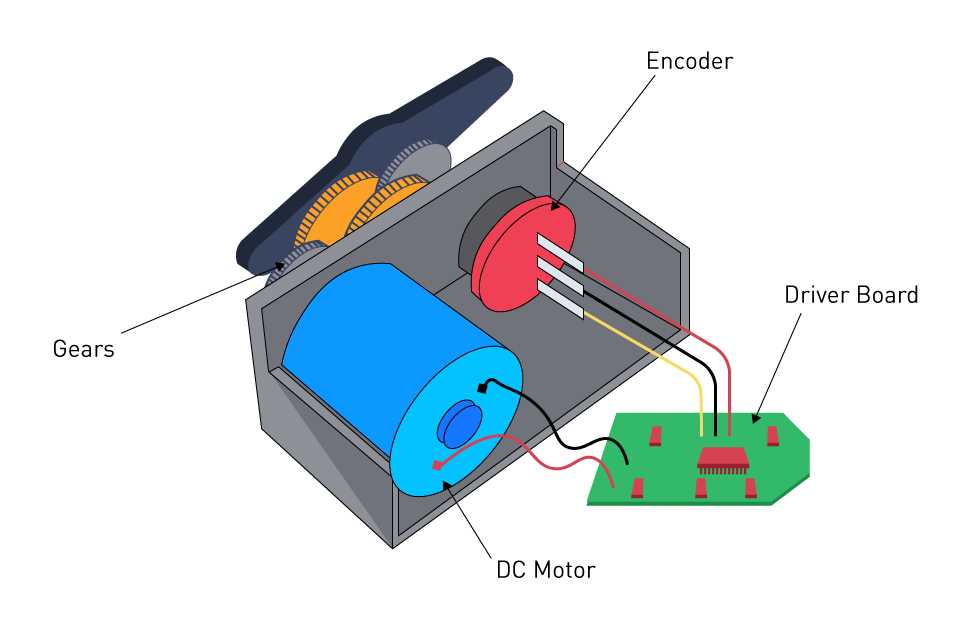

In this guide, we will explore the various components that make up a direct current system. These elements work together to convert electrical energy into mechanical movement, enabling a wide range of applications. Whether for industrial or small-scale use, understanding the core components can significantly improve both maintenance and operation.

Familiarity with these structures helps not only with effective problem-solving but also with enhancing efficiency. Knowing how each piece contributes to the function of the system allows users to recognize when something isn’t functioning as it should, and to address issues before they escalate.

Understanding DC Motor Components

In any electrical system that converts electrical energy into mechanical movement, several interconnected elements are responsible for ensuring its proper functioning. Each component plays a distinct role in the overall operation, affecting the performance and reliability of the entire setup. By examining these internal structures, we gain valuable insight into how energy is transformed and how to troubleshoot potential issues.

Key Elements and Their Functions

The core components include a set of elements designed to interact seamlessly to produce movement. These structures work in harmony to facilitate the conversion of electrical power into motion, and each is crucial for achieving smooth operation. Without these individual pieces, the system would fail to perform as expected, making it essential to understand their functions.

Importance of Proper Maintenance

Maintaining these key components ensures the longevity and efficiency of the entire system. Regular inspection and care of these elements can prevent malfunctions and extend the lifespan of the equipment. Recognizing early signs of wear or dysfunction allows for timely repairs, avoiding costly breakdowns or replacements.

How DC Motors Operate and Function

Understanding how an electrical system converts energy into mechanical movement is fundamental to maximizing its effectiveness. In the case of direct current systems, several processes work together to achieve this transformation. Through the precise interaction of key components, the system is able to generate the required motion for various applications.

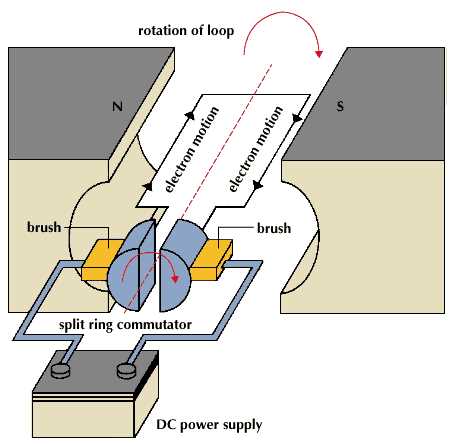

At the heart of this process is the interaction between electrical current and magnetic fields. When the current flows through a conductor placed within a magnetic field, it experiences a force, which causes movement. This fundamental principle is the basis for how the system generates rotation.

Key Steps in the Operation

- The electrical current is supplied to the system, creating a magnetic field around specific components.

- The interaction between this magnetic field and the field from the system’s magnets induces motion.

- The rotation is then transferred to an external mechanism, performing the desired task.

Factors Influencing Efficiency

- Current flow: The amount of electricity passing through the system directly impacts the speed and torque.

- Magnetic strength: Stronger magnetic fields allow for more efficient energy conversion and greater output.

- Design and alignment: Proper alignment of components ensures smooth movement and minimizes energy loss.

Identifying Key Parts in DC Motors

Understanding the internal components of an electrical system that converts energy into motion is crucial for its maintenance and operation. These systems rely on various elements working together to produce consistent performance. Recognizing each part’s function helps in troubleshooting issues, optimizing performance, and ensuring longevity.

Core Components

The primary components include structures that generate magnetic fields, facilitate energy flow, and enable mechanical movement. Each element serves a distinct role that contributes to the overall functionality. Identifying these elements and their connections is essential for understanding how the system functions as a whole.

Commonly Found Elements

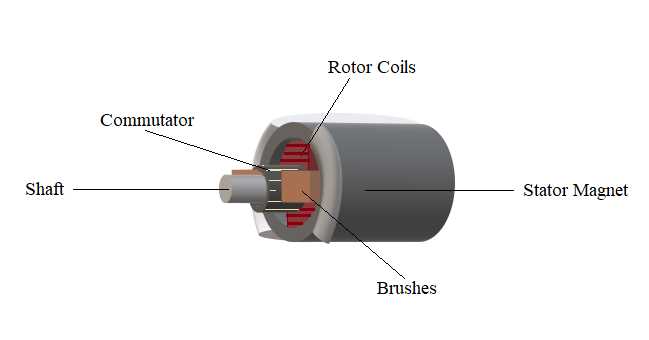

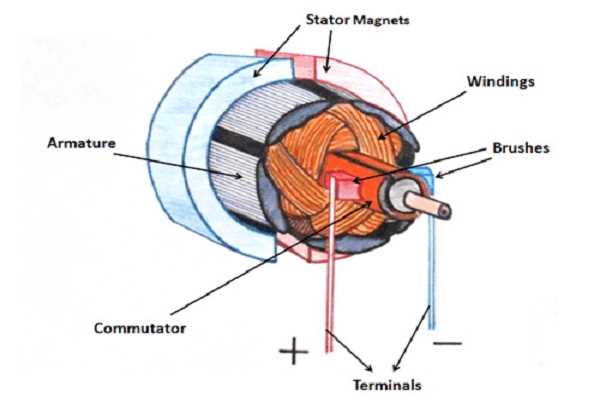

- Commutator: A key component that facilitates the reversal of current direction, enabling continuous rotation.

- Armature: The rotating part of the system, responsible for interacting with the magnetic field to generate movement.

- Brushes: These maintain electrical contact with the commutator, ensuring the flow of current to the armature.

- Magnetic Field Source: Either permanent magnets or electromagnets that generate the necessary field for movement.

DC Motor Diagram and its Importance

Visual representations of complex systems are invaluable tools for understanding their inner workings. These illustrations allow users to clearly identify the connections and interactions between various components, making it easier to comprehend the overall function. When it comes to electrical systems that convert energy into motion, such visual aids are crucial for both learning and troubleshooting.

Such an illustration provides a clear overview of how each element is arranged and how they interact with one another. By mapping out the structure, it becomes easier to pinpoint issues, identify specific components, and understand the flow of energy throughout the system. This clarity helps in ensuring optimal performance and efficient maintenance.

Why Visual Representation Matters

Understanding system layout: A clear diagram helps technicians and engineers visualize the entire setup, facilitating better decision-making during repairs and upgrades.

Effective troubleshooting: When issues arise, a diagram can quickly point to the specific areas of concern, saving time and reducing the complexity of diagnostics.

Common Issues with DC Motor Parts

Like any mechanical or electrical system, devices that convert electrical energy into motion are susceptible to a range of issues that can affect their efficiency and performance. Over time, wear and tear, improper maintenance, or incorrect usage can lead to malfunctioning elements. Identifying these problems early on is key to preventing further damage and ensuring smooth operation.

Common issues often arise from misalignment, electrical faults, or degradation of key components. These problems can manifest in various ways, from reduced efficiency to complete failure. Regular inspection and understanding of how each part functions can help in identifying the root causes and addressing them effectively.

Typical Problems Encountered

- Wear of Brushes: Brushes may wear out over time, leading to poor electrical contact and inefficient energy transfer.

- Commutator Damage: A damaged commutator can result in sparking, noise, and unreliable operation.

- Overheating: Excessive heat can cause components to degrade faster, reducing the overall lifespan and performance of the system.

- Magnetic Field Weakening: If the magnetic field weakens, it may reduce the system’s torque and speed, impacting performance.