When operating advanced watercraft equipment, having a clear understanding of the various components that keep everything running smoothly is essential. Knowing how these elements work together can help in troubleshooting, maintaining, and replacing parts when necessary. This knowledge ensures that the system remains functional and efficient for every outing.

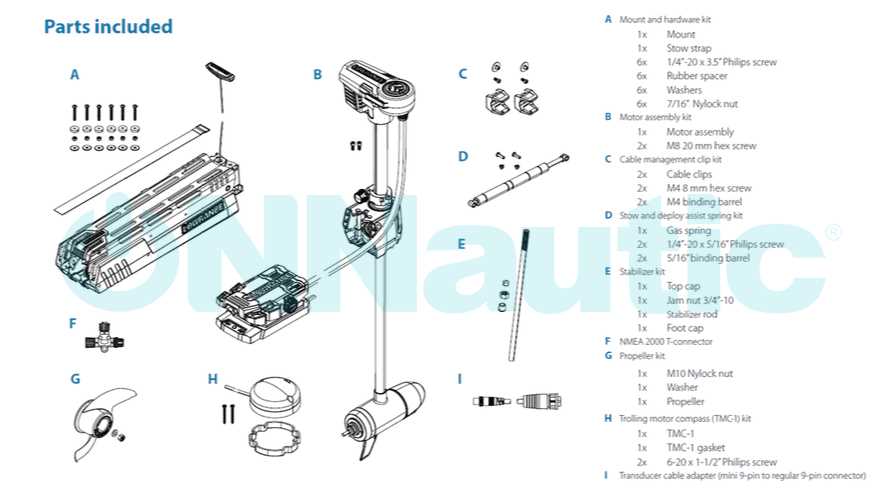

Each device comes with its unique set of elements, each playing a critical role in its overall performance. Identifying these pieces and understanding their functions will allow users to detect potential issues and manage repairs effectively. Whether for regular maintenance or a breakdown, being able to pinpoint the right part is crucial for minimizing downtime and maximizing utility.

Proper care and knowledge of the system’s internal structure can save time, money, and effort. With the right guidance, navigating the components of your equipment becomes straightforward, helping you stay on top of any necessary repairs or upgrades.

Understanding Key Components for Optimal Performance

To maintain the efficiency of your equipment, it is essential to have a clear understanding of the main elements that make it function. Each part plays a unique role in ensuring smooth operation, and being familiar with these components will help prevent issues and extend the lifespan of your device. Whether you’re a seasoned user or new to the system, knowing how each element interacts can lead to more successful outings and fewer unexpected malfunctions.

Core Elements for Seamless Functionality

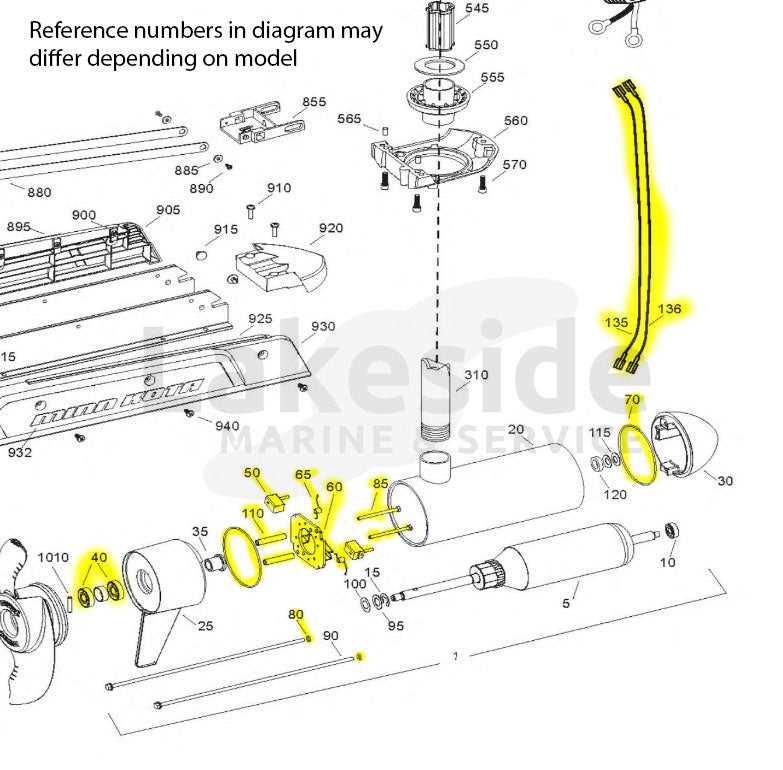

The system consists of several key components that work together seamlessly. From the energy source to the propulsion mechanism, each piece serves a specific function. Understanding the relationship between these elements ensures that users can easily detect when something goes wrong and fix it before it disrupts performance. Regular inspection and familiarity with these components can prevent unnecessary downtime and repair costs.

Critical Components to Monitor Regularly

It is important to pay close attention to certain parts that are more prone to wear and tear. Regular checks of items like connectors, wiring, and control interfaces help avoid more complex issues. By staying proactive and understanding how each part is meant to perform, you can ensure your system stays in peak condition throughout its use.

Identifying Components for Efficient Maintenance

Proper maintenance relies on the ability to identify the various components of your equipment and understand their role in the system. Knowing what to look for and how to address issues before they become major problems can save both time and money. Regular inspection helps keep everything running smoothly, minimizing the risk of malfunctions during use.

Recognizing Key Elements

The first step in efficient upkeep is recognizing the critical elements that require consistent attention. This includes power sources, connection interfaces, and moving components. By familiarizing yourself with these pieces, you can quickly spot wear and tear, preventing more significant damage from developing. A proactive approach will help ensure that each part remains functional and contributes to the overall performance.

Routine Checks and Troubleshooting

Routine checks are essential for preventing disruptions. Regularly inspect electrical connections, seals, and any moving parts for signs of wear. Troubleshooting becomes much easier when you know the key components to monitor, and addressing small issues early on will reduce the likelihood of more costly repairs. This approach ensures that your equipment stays operational and efficient for a longer period.

Common Issues and Replacement Tips

Even with regular maintenance, equipment may experience common issues that can affect performance. Understanding these frequent problems and knowing how to address them is essential for minimizing downtime and ensuring your system continues to operate efficiently. Early detection and timely replacement of faulty elements can prevent more serious malfunctions down the line.

Identifying Common Failures

One of the most common issues users face involves electrical components, such as wiring connections or power supplies. These elements can become loose or corroded over time, leading to intermittent performance. Another issue is the wear of moving parts, which can degrade due to constant use. Identifying these problems early on is key to maintaining reliable functionality and avoiding costly repairs.

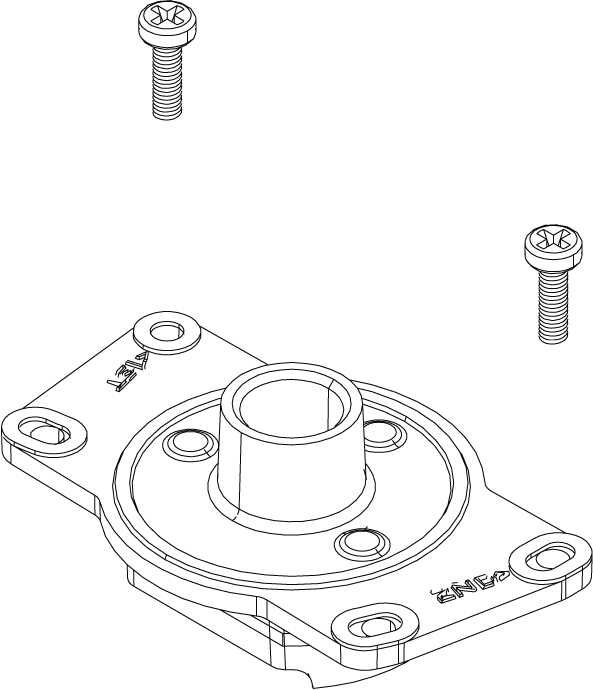

Effective Replacement Practices

Replacing damaged components requires careful selection of compatible replacements to ensure optimal performance. When parts show signs of wear, it’s crucial to find high-quality, suitable replacements that match the original specifications. Always follow manufacturer guidelines to avoid improper installations that could lead to additional issues. Timely replacement of worn parts is an effective strategy for keeping the entire system in top working condition.