When it comes to maintaining your vessel’s drive system, knowledge is key. Understanding the various elements that make up the propulsion setup is crucial for effective troubleshooting and upkeep. Without a clear grasp of how these components interact, even simple repairs can become daunting tasks.

Visual aids such as detailed schematics are an essential resource for anyone attempting to repair or upgrade their boat’s drive system. These diagrams help break down complex structures into understandable sections, allowing for a more straightforward approach to addressing issues. With these tools, you can pinpoint the source of malfunctions and take action with confidence.

Recognizing common faults and knowing how to resolve them is an invaluable skill for any boater. Having a reference to guide you through each step ensures that even less experienced boat owners can perform basic repairs or accurately assess when professional assistance is required.

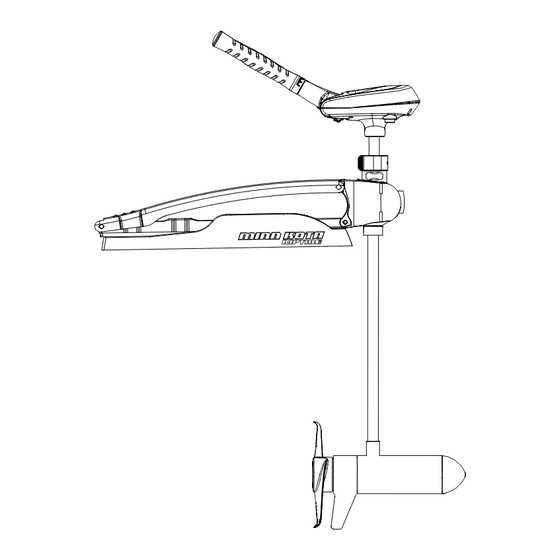

Understanding Boat Propulsion Systems

Effective propulsion is at the core of any boating experience, providing the power needed to navigate waters smoothly and efficiently. While many boaters focus on the general operation of their craft, it’s crucial to understand the underlying mechanisms that drive the system. These setups are made up of a variety of interconnected components, each playing a unique role in ensuring performance and reliability.

Key Components of the Drive System

The primary elements that make up the propulsion system are designed to work in harmony, offering both thrust and control. The unit is typically composed of an electric or gas-powered engine, a propeller or thrust mechanism, and a series of connecting parts that allow for movement and steering. Regular maintenance and understanding how each piece functions will ensure smoother operation and prevent unexpected failures.

How the System Operates

In simple terms, the power source generates the necessary force to propel the boat forward or backward. This force is transferred through various components that convert energy into movement. The connection between the system’s engine and propeller or thrust mechanism is what allows for precise maneuverability. Over time, wear and tear can affect the efficiency of this system, which is why familiarity with each component can help identify and resolve issues faster.

Key Components of a Boat Propulsion System

Understanding the essential components of a boat’s propulsion setup is fundamental to ensuring its optimal performance. Each element of the system plays a vital role in providing the necessary power, control, and movement. These components must be well-maintained and regularly checked to avoid malfunctions that could disrupt the boating experience.

At the heart of the system, the power source generates the force required for movement. This is connected to a propulsion mechanism, typically a propeller, that translates the generated power into forward or backward motion. Additionally, various other components such as the control system, wiring, and mounting equipment work together to ensure seamless operation. Regular inspection of these key parts helps prevent wear and tear, ensuring reliability when out on the water.

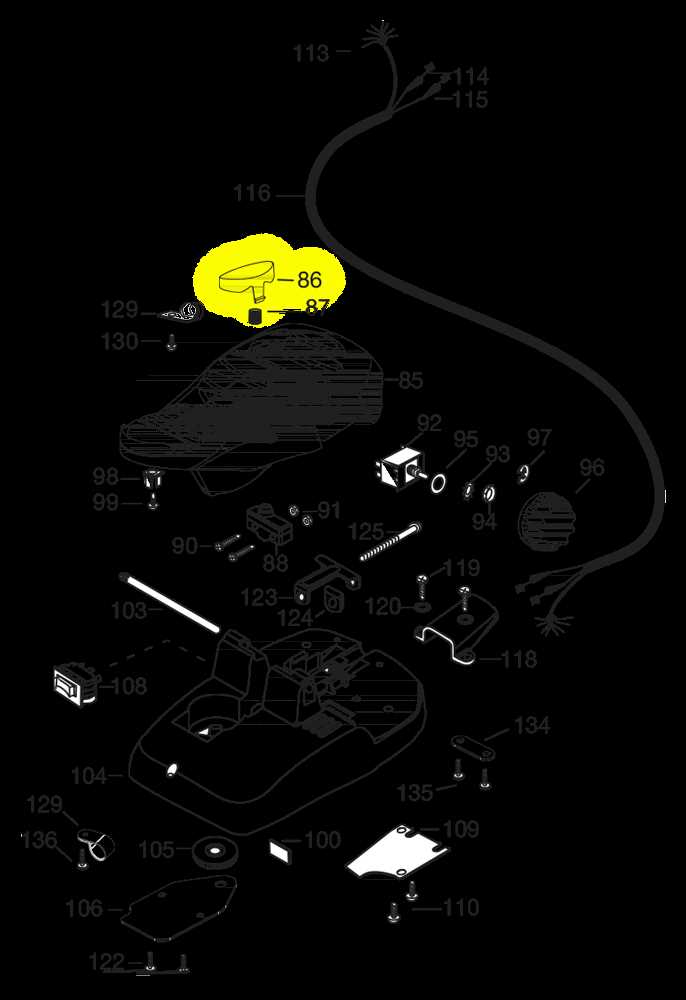

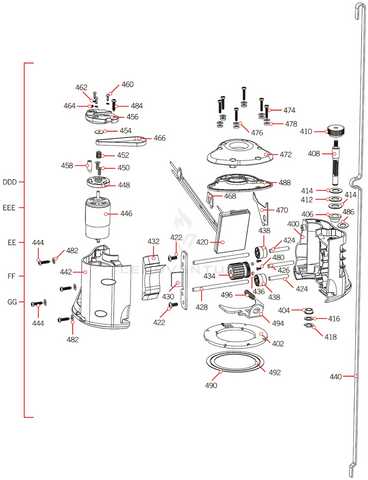

How to Use a Boat System Schematic

Understanding how to read and use a schematic can significantly simplify the process of repairing or maintaining a boat’s propulsion system. These visual aids break down the system into manageable sections, allowing boat owners to identify and address issues more effectively. By familiarizing yourself with the layout, you can diagnose problems with precision and make informed decisions regarding necessary repairs or replacements.

Interpreting the Visual Guide

Each schematic is designed to represent the different components of the propulsion system and their connections. By understanding the flow of energy and how each part interacts with others, you can pinpoint potential areas of concern. Whether you’re dealing with electrical components, mechanical elements, or structural connections, the diagram provides a clear reference for locating and addressing problems.

Step-by-Step Approach to Using the Schematic

To get the most out of the schematic, it’s important to follow a logical sequence. Start by identifying the key sections of the system, then trace the components in order of operation. This will help you determine whether a malfunction lies in the power source, connections, or other parts of the setup. With this step-by-step approach, you’ll be able to take a systematic approach to troubleshooting and repair.

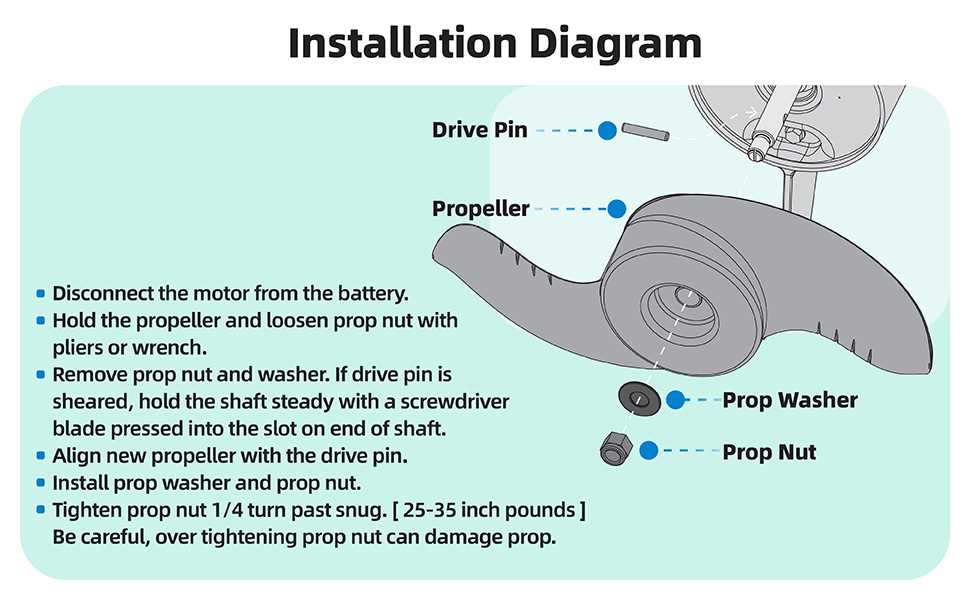

Step-by-Step Repair and Maintenance

Proper maintenance and repair of your boat’s propulsion system are essential to ensure long-lasting performance. Following a structured, step-by-step approach will help identify and resolve issues efficiently. By regularly checking and maintaining the system, you can avoid costly repairs and enhance your overall boating experience.

Step 1: Inspect the System

The first step in maintenance is a thorough inspection of all key components. Regular checks will help identify early signs of wear or damage, which can prevent larger issues from arising. Focus on the following:

- Check for any loose or corroded connections.

- Examine the power source for signs of overheating or wear.

- Ensure the propeller or thrust mechanism is free of debris or damage.

Step 2: Troubleshoot and Replace Faulty Parts

If any issues are found during the inspection, the next step is troubleshooting. Here’s how to approach it:

- Follow the schematic or guide to locate the malfunctioning component.

- Test electrical components for continuity using a multimeter.

- If a part is damaged, order a replacement and install it carefully.

Step 3: Clean and Maintain Regularly

Maintenance doesn’t stop after repairs. Regular cleaning and upkeep ensure the system continues to perform at its best:

- Clean electrical contacts and connections to prevent corrosion.

- Lubricate moving parts to reduce friction and wear.

- Store the system properly when not in use to protect it from the elements.

Common Issues and Troubleshooting Tips

When using any propulsion system, it’s important to be aware of potential problems that can arise during operation. Identifying and addressing these issues promptly ensures a smoother and safer experience on the water. This section highlights some of the most common challenges faced by boaters and offers effective solutions to troubleshoot them.

Power loss is a frequent issue, often resulting from a weak connection or a malfunctioning power source. If your boat is not responding to throttle adjustments, start by checking the battery and wiring for loose connections or corrosion. Make sure the battery is fully charged, and test the electrical system to rule out any issues with fuses or switches.

Unusual noises can indicate that something is wrong with the moving components. If you hear grinding, whining, or a knocking sound, it could be due to a damaged propeller, worn bearings, or debris caught in the system. Inspect these areas, clean out any obstructions, and replace any damaged parts to restore quiet operation.

Inconsistent performance can also be a result of debris clogging the propulsion system or damage to the blades or connectors. Regularly clean the unit to ensure that nothing is obstructing movement. If the issue persists, check for wear on any critical components and replace them as needed to restore full functionality.