Every two-wheeled vehicle relies on a complex system of interconnected elements that work together to ensure smooth movement and stability. These essential components play crucial roles in performance, safety, and durability. A thorough understanding of their structure and purpose is vital for effective maintenance and repairs.

Breaking down these elements involves examining each piece’s specific function and how they contribute to the overall system. By exploring their design, placement, and interaction, owners and enthusiasts can gain deeper insights into how to optimize their vehicle’s functionality and prevent common issues.

In this guide, we will dive into the individual segments, offering clear explanations and helpful tips for interpreting their arrangement. Knowing these fundamentals will aid in more informed decisions when it comes to upkeep and troubleshooting.

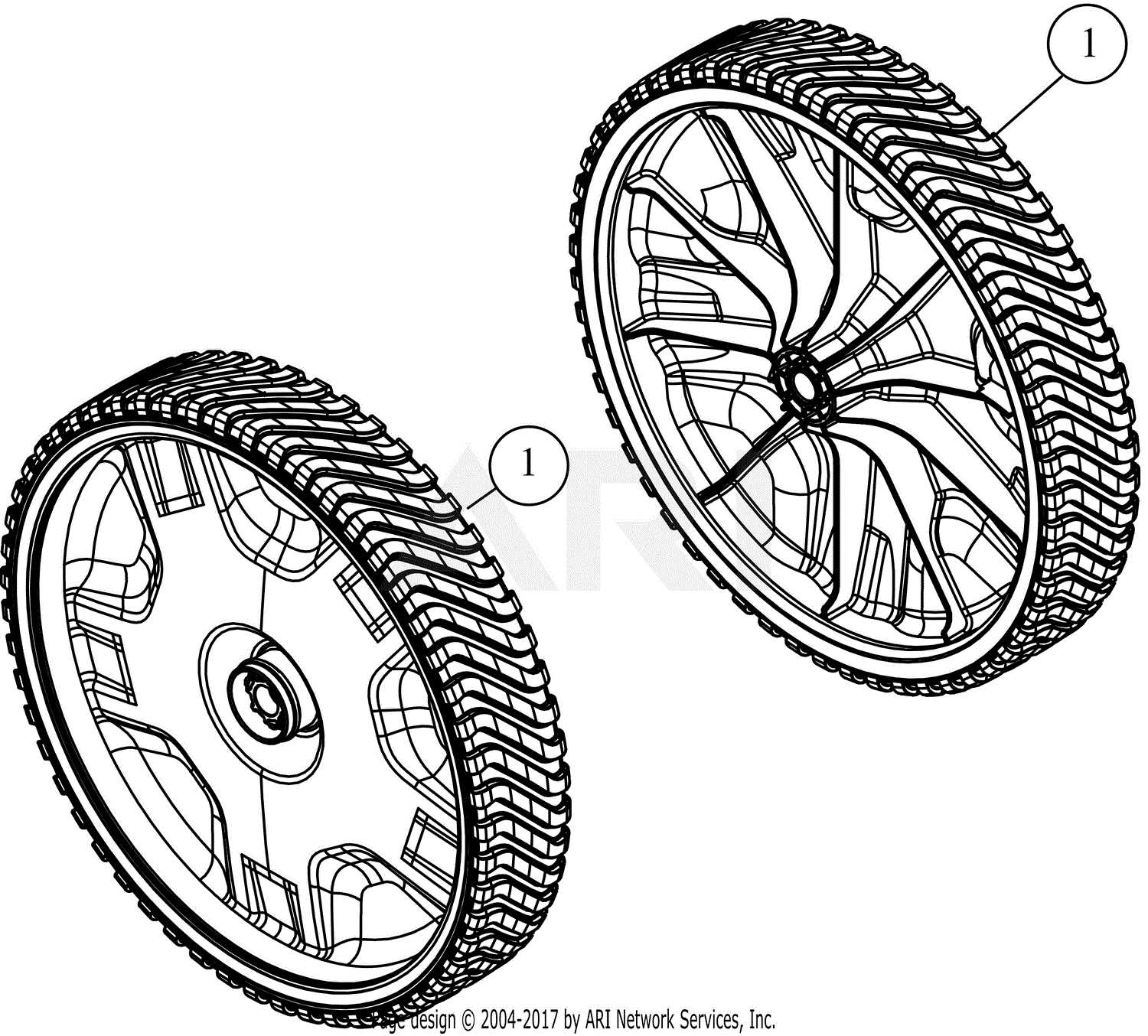

Understanding Motorcycle Wheel Structure

The foundation of any vehicle designed for two-wheel motion relies on a set of integral components that ensure its stability and smooth operation. These elements are designed not only to provide support but also to withstand various stresses during movement. Their proper configuration and functionality are essential for both safety and performance.

Each segment within this system serves a distinct role, working together to maintain balance, traction, and durability. From the core structure to the external elements, the entire system must be optimized for efficient movement across different terrains. Understanding how these components are arranged and interact with one another can greatly enhance the longevity and reliability of the vehicle.

By breaking down the essential pieces and their respective functions, one can gain insight into how they contribute to the overall performance of the entire system. This knowledge can be useful for routine inspections, troubleshooting issues, and performing necessary repairs or upgrades.

Key Components of the Vehicle’s Rolling System

The core elements of the rolling system are designed to support movement while ensuring stability and traction. These segments work together to provide balance and durability, allowing the vehicle to function optimally under various conditions. Each piece within the system plays a unique role that contributes to the overall performance and safety of the machine.

Understanding the key components involves recognizing the functions of each piece, from the central support structure to the external elements. These segments are responsible for managing stresses, absorbing impacts, and ensuring smooth transitions during movement. Each part must be carefully maintained to avoid wear and ensure optimal operation.

By examining the relationship between these components, one can gain valuable insights into how they interact and contribute to the system’s overall efficiency. Recognizing potential issues in these areas can help with routine maintenance and repairs, improving both longevity and performance.

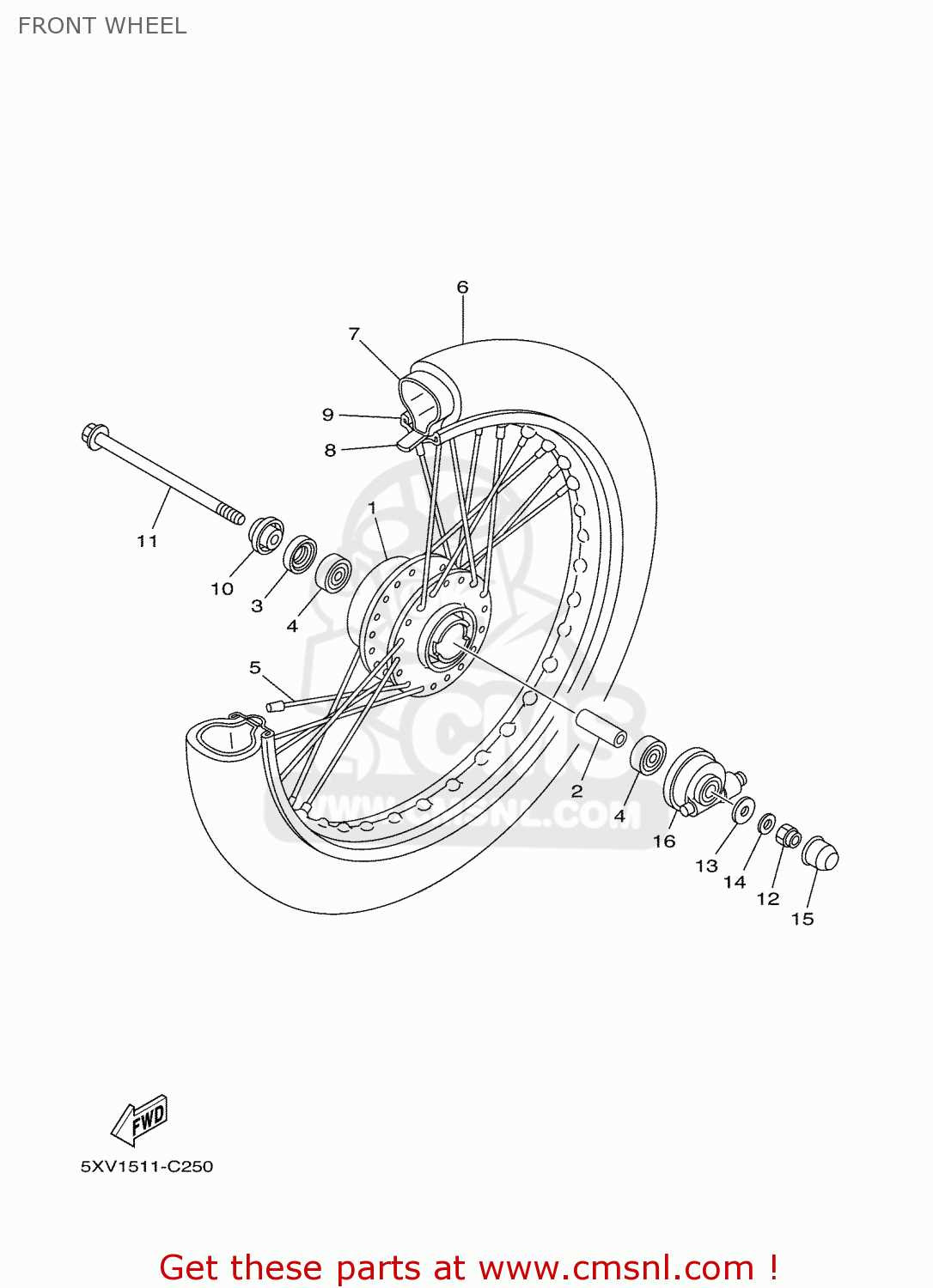

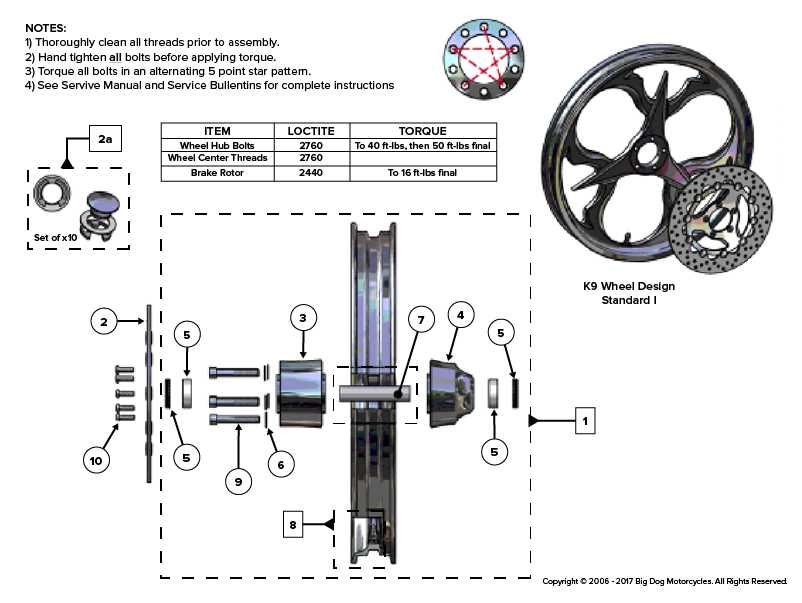

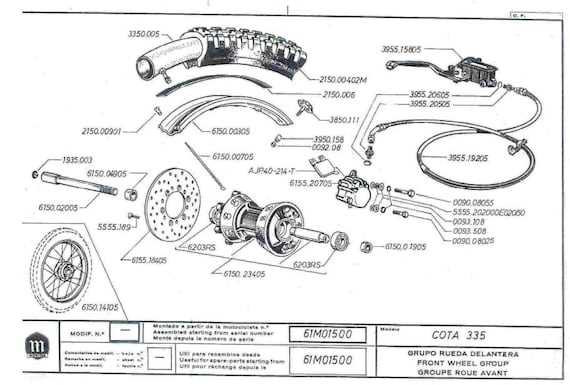

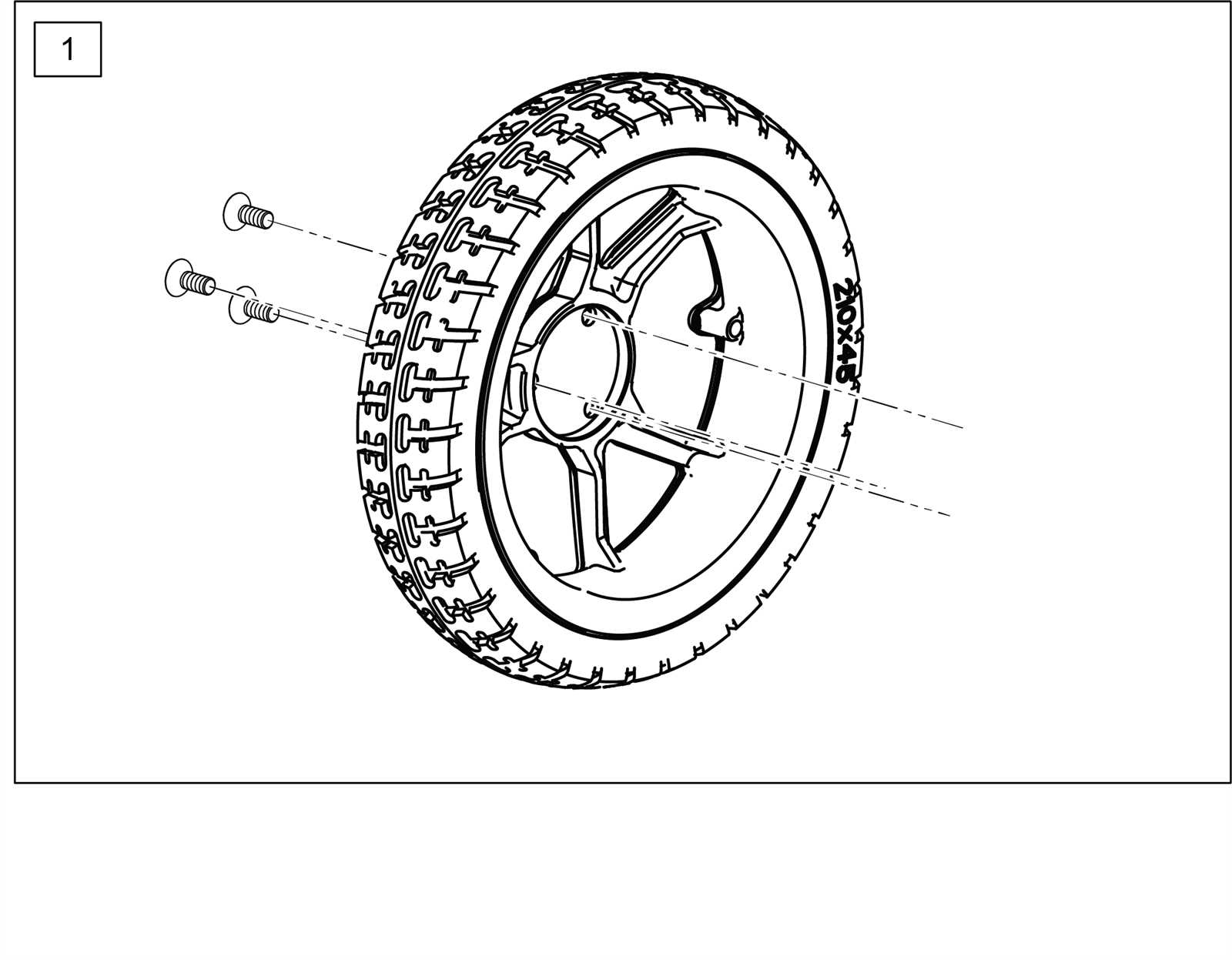

Understanding the Visual Representation

Reading a schematic of a vehicle’s rolling system can initially seem complex, but with a clear understanding of the layout, the interpretation becomes much simpler. Such representations offer a detailed view of how each element is positioned and connected, providing insights into their individual roles and interactions within the system. By recognizing the various symbols and notations, one can gain a comprehensive understanding of the system’s structure.

Interpreting the Labels and Symbols

The first step in interpreting any visual guide is to understand the different symbols and labels used. These elements often represent specific parts or connections, and understanding what each symbol signifies is essential for accurate reading. Labels typically include measurements, material specifications, or direction indicators, all of which contribute to a full understanding of the system’s design.

Understanding Relationships Between Components

The next step is recognizing how the components relate to one another within the layout. Understanding these connections allows for easier troubleshooting and more informed maintenance decisions. Components that are closely linked often share a direct impact on each other’s performance, so being able to spot these relationships is key for managing the system effectively.

Interpreting It for Maintenance

Understanding how to read a system layout is essential for proper upkeep and timely repairs. By accurately interpreting the representation of each component and its relationship to others, one can effectively monitor the system’s health and address potential issues before they become major problems. Maintenance requires identifying areas that are prone to wear, damage, or malfunction, which can be easily spotted by referencing the visual guide.

Spotting Common Issues

A clear understanding of the layout helps identify common issues, such as misalignments, wear on certain segments, or faulty connections. By knowing where specific components are located, you can quickly assess their condition and determine whether they need adjustment or replacement. This proactive approach is crucial for maintaining optimal performance and avoiding unexpected failures.

Optimizing Component Lifespan

Regular inspections using the layout as a reference allow you to spot early signs of wear or stress on certain components. By understanding the role of each segment and how they interact, maintenance tasks can be prioritized, ensuring that parts are serviced before they fail. This careful attention to detail can extend the lifespan of the entire system, keeping it running smoothly for longer periods.

Common Issues in Vehicle Rolling System Components

Over time, various issues can arise within the elements that contribute to a vehicle’s movement. These problems, if left unchecked, can lead to reduced performance, safety risks, and higher maintenance costs. Identifying these common issues early is crucial for maintaining the vehicle’s integrity and ensuring smooth operation.

Common Problems to Look For

Several issues can occur within the rolling system, and understanding the signs of wear or malfunction can help prevent serious damage. Some of the most common problems include:

- Misalignment: Parts may become misaligned due to regular use or external factors, leading to uneven movement and increased strain on surrounding components.

- Excessive Wear: Over time, certain parts can become worn down, reducing their effectiveness and compromising the vehicle’s overall stability.

- Damaged Connections: Connections between components may become loose or damaged, affecting the system’s performance and potentially causing parts to detach during operation.

- Contamination: Dirt, debris, and moisture can enter the system, leading to corrosion and decreasing the lifespan of essential parts.

Preventative Measures

To avoid these issues, regular inspections and timely maintenance are essential. Here are some key steps to take:

- Inspect components regularly for signs of wear, misalignment, or damage.

- Ensure all connections are tight and free from corrosion or debris.

- Perform routine cleaning to prevent the buildup of dirt and moisture.

- Replace worn or damaged parts promptly to maintain optimal performance.