When it comes to maintaining and repairing your trolling motor, having a clear understanding of its individual elements is essential. Knowing how each piece fits together allows for efficient repairs, better performance, and a longer lifespan of your equipment. By familiarizing yourself with the various components and their functions, you can confidently troubleshoot issues and avoid costly mistakes during maintenance.

In this guide, we break down the main components of your motor system, helping you recognize the key pieces and how they contribute to overall functionality. Whether you’re replacing a damaged part or simply performing routine upkeep, this information will ensure you approach the task with a deeper understanding of how each part works.

Taking the time to learn about the structure and assembly of your motor will make all the difference in keeping it in top condition. In the following sections, we’ll dive into the essential components that make up your motor system and provide tips for efficient upkeep.

Understanding Key Motor Components

Every motor is made up of a variety of individual elements that work together to ensure smooth operation. To keep your equipment running at its best, it’s crucial to understand how each component contributes to the overall performance. Recognizing the role of each part allows you to identify problems quickly and efficiently maintain or replace worn-out pieces. This section will help you familiarize yourself with the main components that make up the system and their specific functions.

The following table outlines some of the essential elements of your motor setup. Understanding their purpose will guide you through routine maintenance or troubleshooting tasks. Each part plays a unique role in ensuring that the motor performs optimally and lasts longer with proper care.

| Component | Function |

|---|---|

| Motor Housing | Encloses internal components and protects them from damage. |

| Propeller | Provides thrust by pushing water, enabling movement. |

| Steering Mechanism | Allows for precise directional control of the motor. |

| Power Supply | Delivers electrical energy to power the motor’s functions. |

| Control Module | Manages motor speed and performance settings. |

By understanding these critical components, you can better care for your motor system, troubleshoot effectively, and ensure everything is running smoothly. Each element serves a vital role in the overall functionality, and paying attention to their condition is key to avoiding issues during operation.

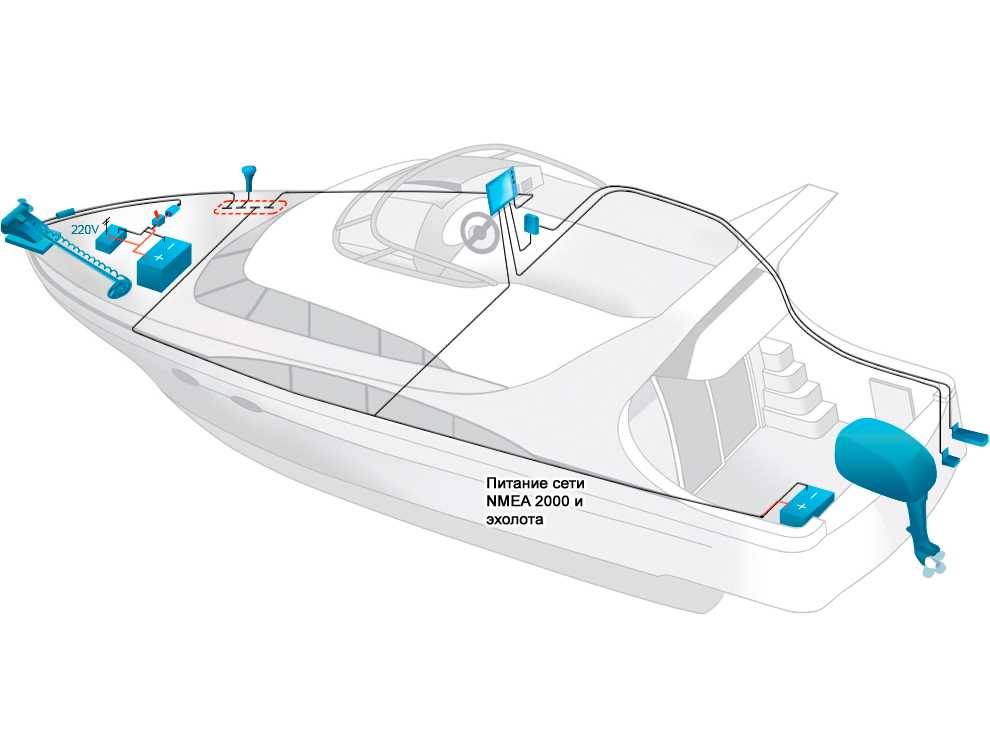

Identifying Key Components in the Diagram

When reviewing the visual representation of your motor system, it’s important to recognize each individual part and its function. A clear understanding of how each component fits into the overall structure will allow you to identify specific issues and perform maintenance with ease. This section will guide you through the essential elements, highlighting their significance and placement in the system.

Recognizing Essential Parts

Each part of the motor is strategically placed to ensure smooth operation. The most important components are typically larger and centrally located in the diagram. For example, the main housing protects the internal electronics, while the propeller is placed at the bottom to ensure maximum water movement. By focusing on these critical elements, you can easily pinpoint where repairs or adjustments may be needed.

Reading the Breakdown

In the visual representation, you’ll often see lines connecting different components. These lines help you trace the connections and relationships between parts. Understanding these links will enable you to identify how the entire system functions and how each part influences the performance of others. Familiarizing yourself with this layout is an essential step in maintaining or troubleshooting your motor efficiently.

Step-by-Step Guide to Assembly

Assembling your motor requires careful attention to detail and a clear understanding of each individual component. Following a structured approach will ensure that all parts fit correctly, contributing to the overall functionality of the system. This guide will walk you through the assembly process, breaking it down into manageable steps that will help you complete the task with precision and confidence.

Start by organizing all the necessary components and tools. Ensure you have a clean workspace and that each part is easily accessible. Begin with the largest and most foundational pieces, such as the motor housing or base. Secure these parts first, as they provide the structure for the rest of the assembly. Afterward, proceed with adding smaller components, ensuring they are properly aligned and connected.

As you continue, take your time to check each step before moving on to the next. Once the assembly is complete, verify that all parts are securely fastened and functioning as intended. By following these steps carefully, you can achieve a fully operational system that will perform at its best.

How to Read the Parts Breakdown

Understanding a visual breakdown of your motor system is key to identifying each individual element and how they interact. These breakdowns often provide a detailed view of the system, showing the arrangement and function of each part. Knowing how to read this information allows you to pinpoint specific components for repair, replacement, or maintenance.

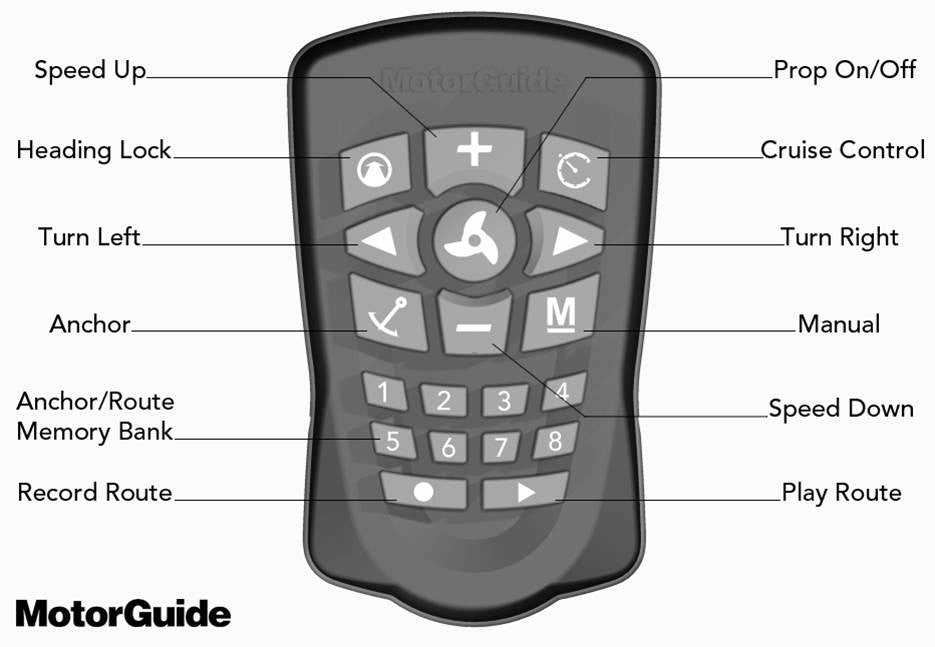

To begin, focus on the labeling system used in the breakdown. Each component is usually marked with a number or letter, which corresponds to a list that provides further details about its function and specifications. Here’s how to read the breakdown effectively:

- Look for groupings: Components are often grouped by function, such as electrical or mechanical parts. Identifying these groups helps in understanding how each part contributes to the overall performance.

- Note the connections: Lines or arrows between parts show how they are linked together. These connections are essential to understanding how the system operates as a whole.

- Check for part identifiers: Each part should be labeled clearly with a number or letter. Refer to the corresponding list to gain more detailed information about its function and specifications.

By following these steps, you can gain a clear understanding of how each part fits into the larger system, making it easier to troubleshoot, maintain, or replace components as needed.

Maintaining Your Motor System

Regular maintenance is essential for keeping your motor in optimal working condition. Proper care can extend the lifespan of the system, prevent costly repairs, and ensure that it performs reliably when you need it most. In this section, we’ll discuss essential maintenance tasks and provide tips on how to keep your motor running smoothly.

Routine Inspections and Cleaning

One of the most important steps in maintenance is conducting regular inspections. Look for any signs of wear or damage on external components and ensure that all parts are securely fastened. Cleaning is also crucial to remove debris, dirt, and saltwater residue that can build up over time. Use a soft cloth and mild cleaning agents to avoid damaging sensitive components.

Lubrication and Electrical Care

Lubricating moving parts helps prevent rust and ensures smooth operation. Pay particular attention to areas where friction occurs, such as the propeller shaft. Additionally, regularly check the electrical connections for signs of corrosion and ensure that the power supply is functioning correctly. A well-maintained electrical system is key to ensuring reliable performance.

By incorporating these routine tasks into your maintenance schedule, you can ensure that your motor remains in excellent condition and ready for use at all times.