Understanding the essential components of your lawn equipment is crucial for maintaining optimal performance. A detailed reference to the various elements involved ensures that any issues can be quickly diagnosed and resolved. Whether you’re a seasoned expert or a beginner, having a clear view of each section helps simplify repair and upkeep tasks.

Proper maintenance is vital for prolonging the lifespan of your outdoor machinery. By gaining familiarity with each individual part, you can easily recognize wear and tear or detect potential problems before they worsen. This guide provides an invaluable tool for improving your repair process and keeping your equipment in peak condition.

Knowing how to properly manage and address each component in the system can lead to smoother operation and fewer disruptions. Regular inspection and care are key to avoiding costly repairs and enhancing the overall effectiveness of your outdoor tools.

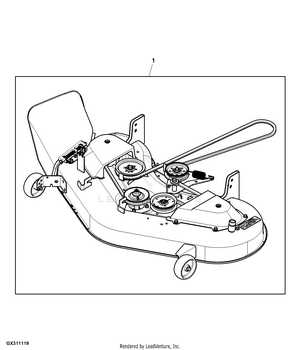

Understanding the 48 Inch Mower Layout

For efficient lawn maintenance, it is important to familiarize yourself with the setup of your outdoor equipment. Knowing how the different elements interact with each other allows for better troubleshooting and optimal functionality. The layout provides a clear map of the key components, ensuring smoother operation and simplifying repairs.

Key Components of the Layout

The layout includes various sections that perform specific functions. Understanding each part’s role helps to ensure effective maintenance and proper usage. Here are some critical components to consider:

- Blade assembly: Responsible for cutting the grass efficiently, this section requires regular inspection for sharpness and damage.

- Spindles: These components support the rotating blades and should be checked for wear and lubrication.

- Belts: Belts transfer power between different parts of the system and need to be tight, free from cracks, and properly aligned.

- Frame: The main structure that holds everything in place. It’s important to keep the frame free from rust and damage.

Why Understanding the Layout Matters

When you have a solid grasp of the layout, you can quickly identify any areas that may need maintenance or replacement. This understanding saves time, reduces the chances of malfunction, and helps keep the equipment running smoothly. Additionally, it empowers users to tackle basic repairs and adjustments independently, minimizing downtime.

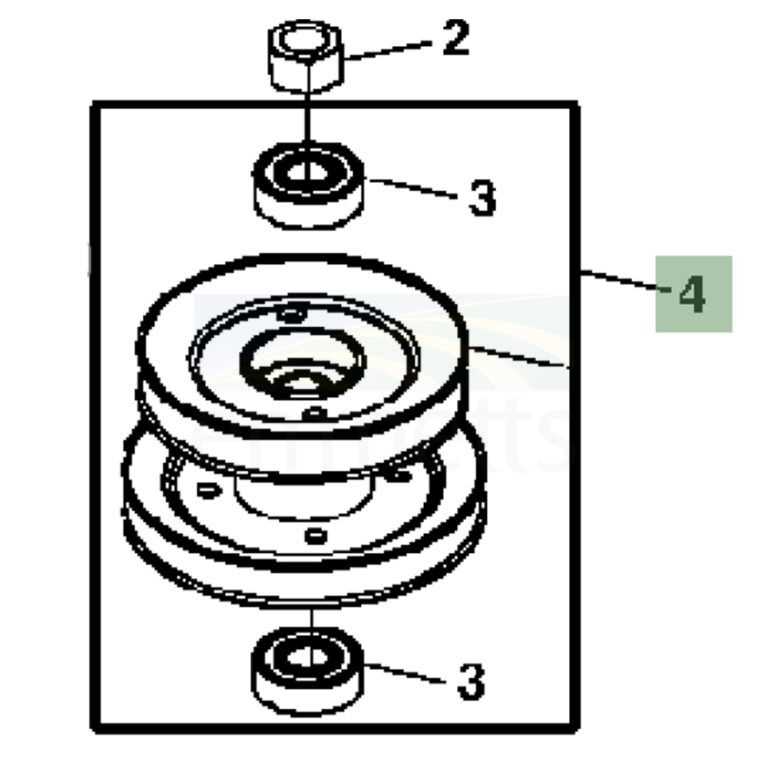

Identifying Key Components in the Layout

Understanding the individual elements of your lawn equipment is essential for effective troubleshooting and maintenance. Each section of the layout serves a specific purpose, and recognizing these parts allows for more efficient repairs and performance improvements. Proper identification helps to avoid unnecessary replacements and ensures your machine operates at its best.

Critical Sections to Recognize

The layout showcases several key sections, each with distinct roles in the overall functioning of the system. Here are the most important components to identify:

- Blade assembly: Responsible for cutting the grass, the blade assembly must be kept sharp and in good condition to ensure clean and even cuts.

- Transmission system: Transfers power from the engine to other parts of the equipment. It’s crucial to check for any signs of wear or damage.

- Support bearings: These small but vital components help maintain smooth movement of rotating elements. Regular inspection is necessary to avoid wear and prevent breakdowns.

- Drive belts: These belts control movement and power distribution. They must be properly aligned and tensioned to prevent slippage or damage.

Why Proper Identification Is Crucial

Accurately identifying the components allows you to diagnose problems more efficiently, reducing the time spent on repairs. By understanding how each section contributes to the overall function, you can quickly address potential issues before they affect performance. Moreover, it gives you the confidence to handle routine checks and maintenance tasks on your own.

How to Use the Layout for Repairs

Utilizing a detailed layout for repairs can significantly streamline the process, allowing for quicker identification of issues and more precise fixes. By following the provided reference, you can pinpoint the malfunctioning components and determine the best course of action. Understanding how each part fits into the overall system aids in more effective and accurate repairs.

Start by carefully reviewing the layout and locating the section where the issue has occurred. Once identified, focus on the associated components, checking for damage or wear. The layout provides a visual guide to help you understand how parts interact, making it easier to understand how the failure may have occurred.

When performing repairs, use the layout as a step-by-step reference. This ensures you tackle the right areas first and avoid unnecessary disassembly. It also helps in determining whether a part can be repaired or if it needs replacement. With a clear guide, you can save time, reduce mistakes, and perform more efficient maintenance.