When it comes to maintaining and repairing outdoor machinery, having a clear understanding of its structure is essential. Knowing where each part fits and how it works together can make a significant difference in the efficiency of any maintenance task. Familiarity with the machine’s layout ensures that problems can be identified and addressed quickly, avoiding unnecessary delays or costly repairs.

Efficient troubleshooting begins with a detailed map of the key elements that make up the machinery. Having a visual reference helps in pinpointing issues that might not be immediately obvious. Whether you are replacing a broken component or performing routine checks, understanding the assembly can save time and effort.

Using an organized reference guide allows for a streamlined approach to managing any equipment. Such guides break down the machine into its most important parts, highlighting their connections and functions. This method simplifies even the most complex tasks, enabling quick and effective fixes.

Understanding Bobcat Mower Part Names

Properly identifying the components of any outdoor machinery is crucial for effective maintenance and repairs. Each part has a specific role, and knowing their names and functions helps streamline the repair process. When working with such equipment, it’s important to understand the terminology used to describe the various sections of the system.

Every machine is made up of several key sections that work together to perform its tasks. These include the main engine, drive system, cutting components, and support structure. To keep things organized and easy to manage, these sections are often broken down into smaller units that are easier to identify and replace.

- Engine components: The heart of the machine, providing the power needed to drive all functions.

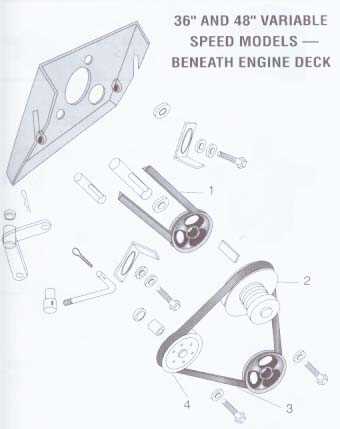

- Drive system: Includes parts like belts, pulleys, and transmission systems that help move the machine.

- Cutting elements: These are the blades and mechanisms responsible for performing the cutting task.

- Frame and support: The framework that holds all components together and provides stability during operation.

Familiarizing yourself with these terms allows for a more efficient approach to machine maintenance. Once you recognize the names of these sections and their role, you’ll be able to make more informed decisions when it comes to repairs and replacements.

Identifying Key Components for Maintenance

Regular upkeep of outdoor equipment relies heavily on knowing which components require attention. By focusing on the crucial parts, you can prevent breakdowns and extend the lifespan of the machinery. Identifying these areas ensures that each part is functioning properly, leading to better performance and fewer repairs.

Essential Areas to Inspect

The key components that should be regularly checked include the engine, the drive system, and the cutting mechanism. These elements are critical for the smooth operation of the equipment. Failing to maintain any of these parts can lead to inefficiency or even complete failure during use.

Understanding Wear and Tear

Some components are more prone to wear and tear than others due to constant use and exposure to harsh conditions. Identifying parts that commonly degrade over time, such as belts, blades, or filters, is essential. Keeping a close eye on these parts and replacing them when necessary can help avoid costly repairs and downtime.

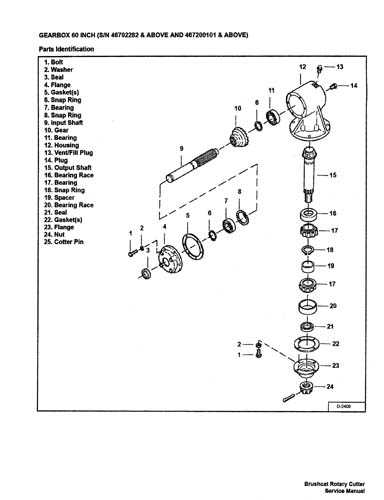

How to Use a Bobcat Parts Diagram

Using a detailed reference guide for machinery components can simplify the repair and maintenance process. A visual representation of the equipment’s structure allows for quick identification of each part, making it easier to understand where each component fits and how it functions. This tool is indispensable for those who prefer to tackle repairs independently or need to ensure everything is correctly assembled.

Locating Specific Components

Start by locating the area of the equipment that needs attention. Each section of the guide typically organizes the components into categories such as the engine, drive system, or cutting apparatus. Once you identify the section you’re dealing with, the diagram will help you pinpoint the exact part in need of replacement or repair.

Understanding Connections and Functions

Another important aspect of using a visual reference is understanding how parts connect and interact with each other. Studying these relationships helps you avoid mistakes during disassembly or reassembly. By carefully following the layout provided, you can ensure that each part is aligned properly and functioning as it should.