Knowing the different elements of your lawn equipment and how they function together is essential for keeping it in optimal condition. Whether you’re a seasoned user or just beginning, understanding the structure of the machine can help streamline repairs and maintenance.

In this section, we will break down the key components that play a role in the performance of your device. By familiarizing yourself with these crucial elements, you’ll be able to troubleshoot issues, replace damaged parts, and enhance the overall longevity of the machine.

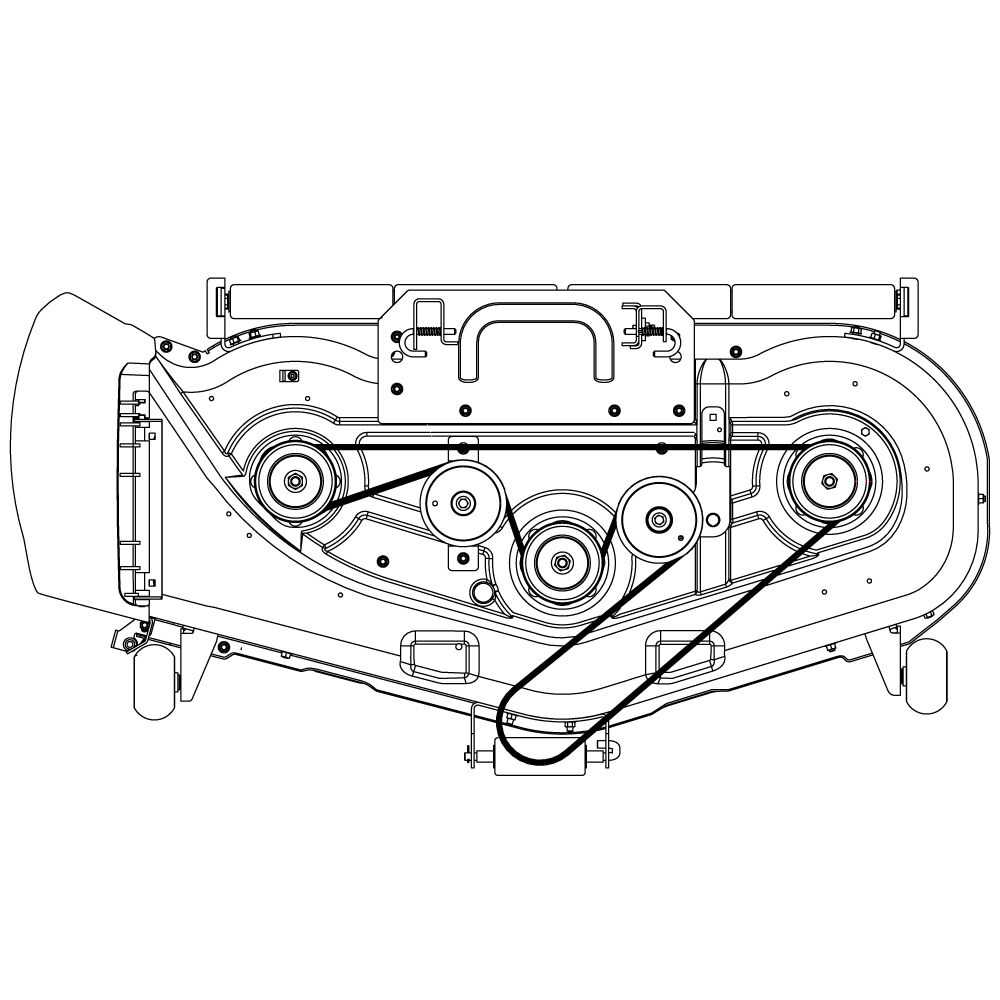

Utilizing a clear schematic representation is vital for identifying and understanding the connections between various components. It provides valuable insight into the assembly and guides you in performing tasks like repairs and upgrades.

Understanding the Craftsman Mower Deck Components

Effective lawn care equipment requires an understanding of its internal structure. Recognizing how each element works together allows for smoother operation and easier troubleshooting. By exploring the crucial elements involved in the machine’s functioning, you can ensure a more efficient and durable performance.

Key Functional Elements

At the heart of the system, the blades, belts, and pulleys collaborate to provide precise cutting results. These components play significant roles in controlling the movement and power required for operation. Familiarizing yourself with these key parts makes it easier to diagnose issues and maintain the device efficiently.

Assembly and Maintenance Considerations

Proper assembly ensures the system operates smoothly, while regular maintenance extends its lifespan. Regular inspection of each part helps avoid wear and tear, which can disrupt performance. Understanding how the elements fit together aids in timely repairs, ensuring your equipment remains in top shape.

Key Parts of the 50 Inch Mower Deck

Understanding the essential components of your lawn care equipment is vital for its efficient operation. These components work together to ensure smooth performance and reliable results. Familiarizing yourself with each key element can help prevent problems and improve maintenance efforts.

Among the most important elements are the cutting blades, which are responsible for achieving a clean, even cut. Additionally, the drive belts and pulleys play crucial roles in transferring power from the engine to the blades. Other vital components, such as the spindles and bearings, support the movement of the blades and help maintain their rotation.

How to Use the Diagram for Repairs

When it comes to performing repairs, a clear visual representation of the internal components can be incredibly useful. A well-organized guide helps you identify each part, ensuring that any replacements or adjustments are done accurately. It also simplifies the process of troubleshooting by highlighting common areas that may require attention.

Step-by-Step Troubleshooting

Start by examining the schematic to understand how each element interacts with the others. This allows you to pinpoint areas where issues may arise, such as damaged belts or misaligned components. Once the problem is identified, you can refer to the diagram to ensure proper installation of replacement parts.

Effective Maintenance and Replacements

For ongoing maintenance, regularly consulting the visual guide can help you maintain the equipment’s performance. It serves as a reference for proper part placement and assists in identifying worn or damaged elements. Regular checks and replacements can prevent breakdowns and extend the equipment’s lifespan.