When it comes to maintaining outdoor machinery, having a clear understanding of its key components is crucial. Each piece plays a vital role in ensuring smooth operation and longevity. Familiarizing yourself with how these elements interact can help you address issues efficiently and improve the overall performance of your equipment.

Recognizing the core elements is the first step toward effective care. Every machine consists of interconnected systems, and knowing the function of each section allows for quicker troubleshooting and more accurate repairs. From the engine to the drive mechanism, each part must be in optimal condition for the machine to operate at its best.

Regular maintenance is essential for preventing breakdowns and extending the lifespan of your equipment. Proper attention to detail during servicing, based on a thorough understanding of the machine’s structure, can make all the difference in keeping it running smoothly for years. Identifying components early on helps avoid major repairs in the future and ensures that every task is completed with ease.

Understanding Garden Equipment Components

For efficient operation and maintenance, it’s essential to have a clear grasp of the various elements that make up outdoor machinery. Each component serves a specific purpose, contributing to the overall functionality and reliability of the equipment. Gaining insight into how these pieces interact allows for better decision-making when it comes to repairs and upkeep.

Core Elements of Outdoor Machinery

The engine, transmission, and control mechanisms are the primary components that drive the machine. These parts work together to provide power and precision in operation. A malfunction in any of these sections can lead to inefficiency or total failure, making their proper functioning critical to the overall performance.

Maintaining and Troubleshooting Key Components

Understanding how to identify and address issues with each piece is vital for routine maintenance. Regularly checking the engine, belts, and moving parts ensures they are in good working order. With the right knowledge, minor adjustments can be made before they develop into costly problems. Proactive maintenance can greatly extend the lifespan of your equipment, reducing the need for extensive repairs.

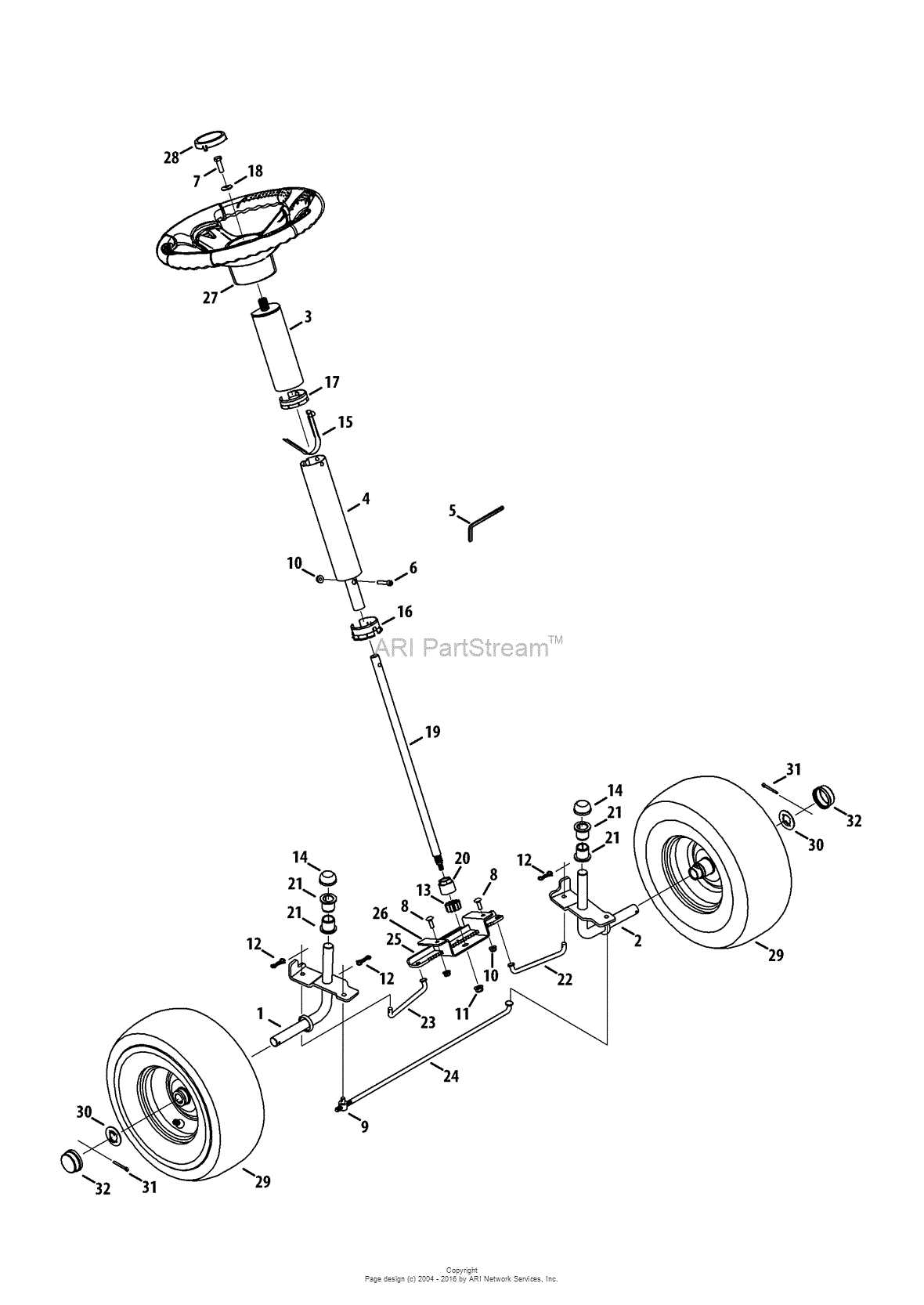

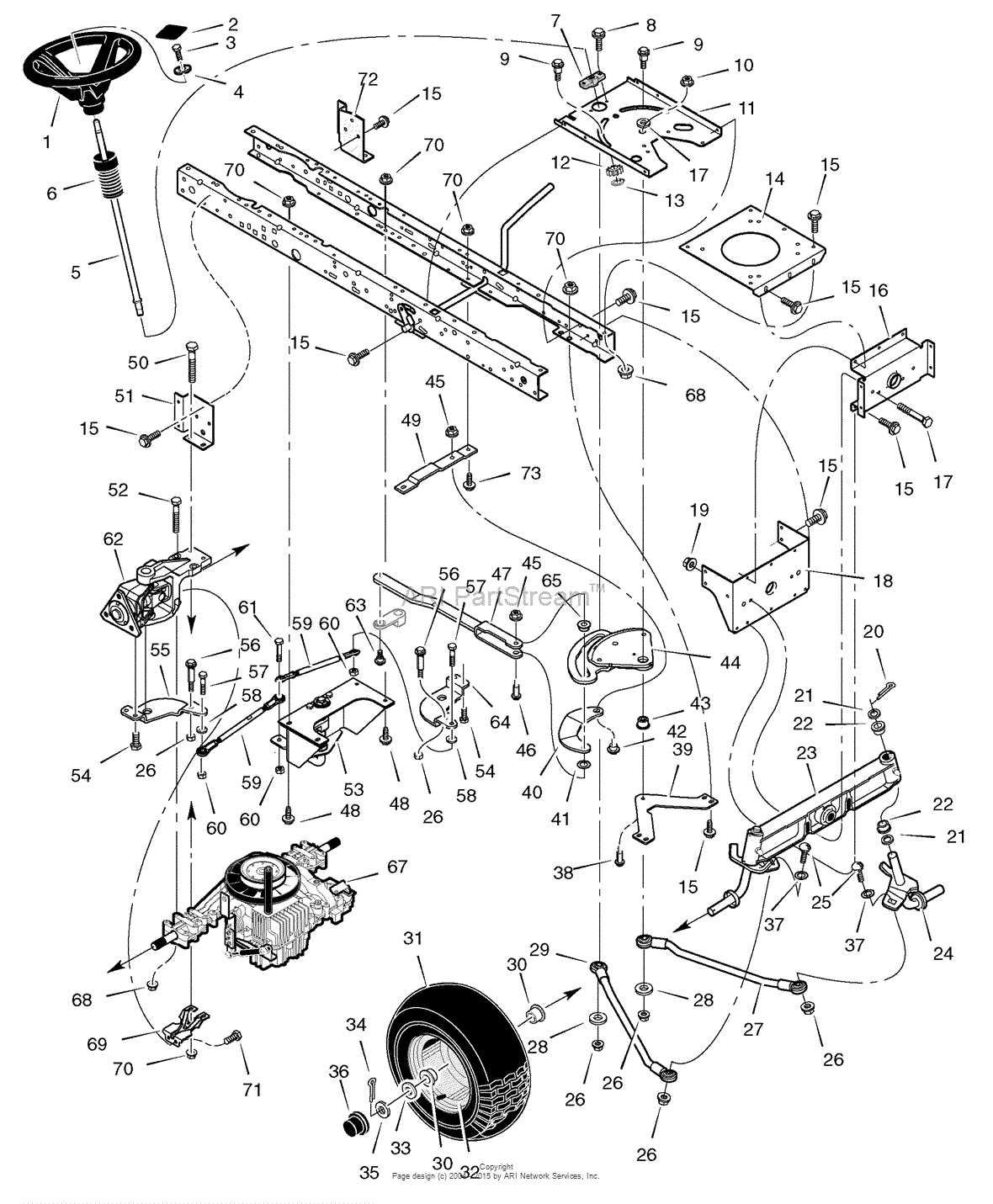

Identifying Key Parts in the Diagram

Understanding how different components of outdoor machinery are organized and connected is essential for effective maintenance and repair. By recognizing each part and its function, you can easily pinpoint any issues and take the necessary steps to fix them. A clear map of the equipment’s structure helps simplify the troubleshooting process and allows for quicker, more accurate repairs.

Commonly Found Sections

Some of the most important sections to focus on are the engine, transmission, and power delivery system. These elements are responsible for generating and transferring power throughout the machine. Any disruptions within these areas can cause significant performance issues. Identifying their specific locations and functions is the first step in diagnosing potential problems.

Locating Other Essential Elements

Other essential components, such as control mechanisms, drive belts, and safety features, should also be closely examined. These smaller parts work together to ensure smooth operation and provide safety during use. By familiarizing yourself with their positions and roles, you can quickly identify wear or damage that may need attention.

Tips for Efficient Equipment Maintenance

Regular upkeep is crucial for ensuring the longevity and peak performance of any outdoor machinery. A well-maintained machine will operate more efficiently, require fewer repairs, and provide a smoother user experience. Knowing the right maintenance tasks to prioritize can help prevent costly breakdowns and extend the life of your equipment.

Routine Checks and Adjustments

Performing frequent inspections of key components, such as the engine and belts, is essential. Make sure to clean any debris from moving parts, check for wear, and replace any damaged sections promptly. Staying on top of these routine checks can help catch small issues before they turn into larger, more expensive problems.

Proper Storage and Care

When not in use, ensure that your equipment is stored in a dry, protected area. This prevents rust and other forms of damage caused by exposure to the elements. Additionally, regularly lubricate moving parts and replace any filters to maintain optimal performance. Proper storage and routine care are key elements in keeping your equipment running smoothly season after season.