Maintaining lawn care equipment is essential for ensuring long-lasting performance. Familiarizing yourself with its individual elements and how they function together can greatly enhance your ability to troubleshoot and perform routine maintenance tasks.

Knowing the specific components and their interconnections can help in diagnosing issues and replacing faulty elements. Whether you’re looking to repair or upgrade your equipment, a clear understanding of its structure is vital for achieving the best results in keeping your lawn pristine.

Proper maintenance not only improves performance but also extends the lifespan of your machinery. Identifying and selecting the right components for repairs is key to preventing costly mistakes and ensuring smooth operation over time.

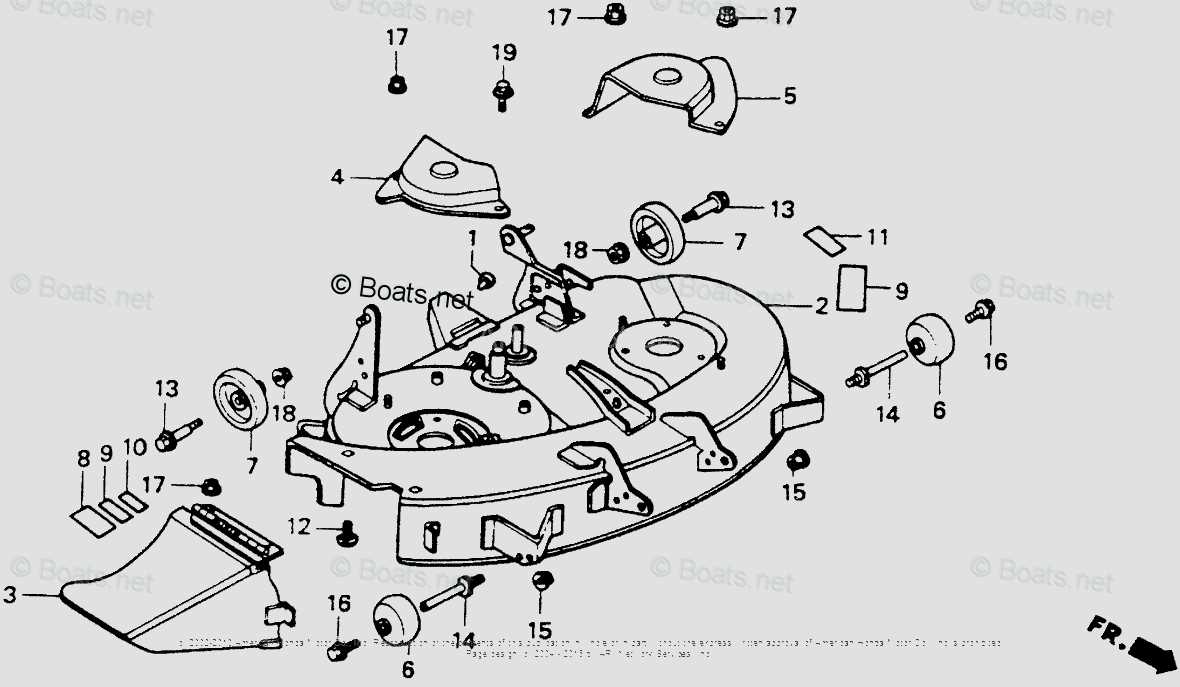

Identifying Key Components of Mower Deck

Understanding the various components that make up your equipment is crucial for efficient maintenance and repair. Each element plays a specific role in the overall functionality, and identifying them properly can help you address issues more effectively. Knowing these components allows you to perform necessary inspections and repairs, keeping the machine running smoothly for a longer period.

Below is a table highlighting the key elements found within the structure of the cutting mechanism, along with their functions. This will guide you in identifying the parts and understanding their purpose in the system.

| Component | Description |

|---|---|

| Blade | Responsible for cutting the grass efficiently. A sharp, well-maintained blade ensures clean cuts. |

| Spindle | Supports the rotating blades and transfers power from the engine to the blades. |

| Belt | Transmits power from the engine to the spindles, allowing the blades to rotate. |

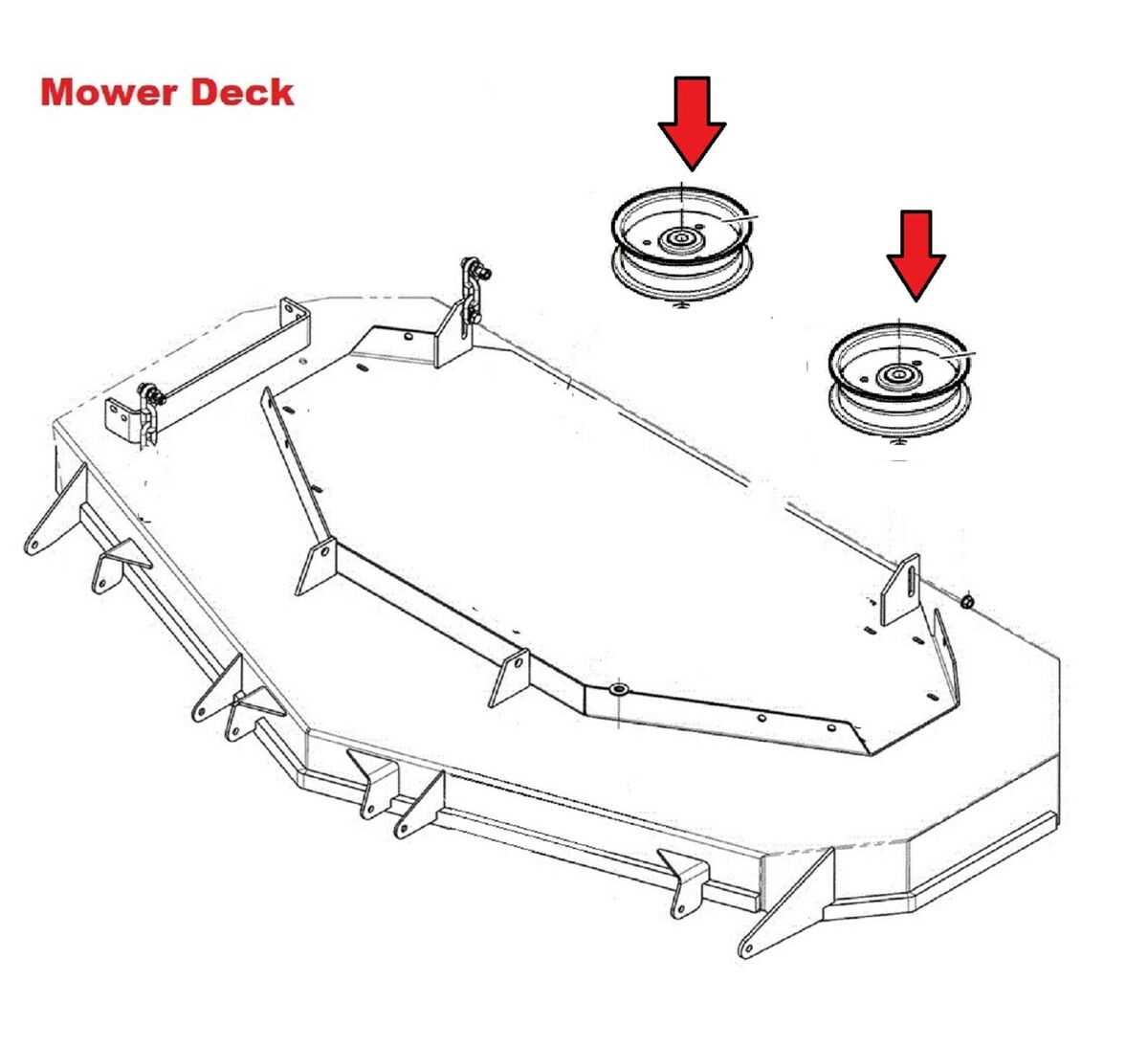

| Pulley | Helps in the transfer of rotational force to various parts of the system, ensuring smooth operation. |

| Chassis | Forms the main body of the equipment, holding all components in place and providing structural integrity. |

Understanding the Assembly and Structure

Each piece of lawn equipment is designed with a specific assembly to ensure optimal performance. Understanding how these components come together is essential for proper operation and troubleshooting. The arrangement and interconnection of parts within the system allow for the efficient execution of tasks such as cutting, propulsion, and maneuvering.

The structure consists of multiple interconnected sections that work in unison. These parts must be correctly aligned and maintained for the system to function properly. Below is a breakdown of the key sections and their roles in the overall design:

- Power Transmission System: This section transfers power from the engine to the functional components, including the cutting mechanism.

- Cutting Assembly: Comprising various blades and spindles, this area is responsible for performing the main task of trimming the grass.

- Support Frame: The main structure that holds all the components in place, ensuring durability and stability during operation.

- Control Mechanisms: These allow the user to adjust the speed, height, and other settings that affect the performance and efficiency of the equipment.

Each section is integral to the functioning of the whole system, and proper maintenance of each part ensures long-lasting, reliable performance. Regular checks and care will help avoid potential malfunctions and improve the overall effectiveness of the machine.

Common Issues with Mower Deck Parts

When using lawn equipment, certain components may begin to experience wear and tear over time. Recognizing and addressing these common issues early can prevent costly repairs and help maintain the equipment’s efficiency. Many problems arise from simple maintenance neglect or improper adjustments, affecting the overall performance.

Worn or Dull Blades

One of the most frequent issues is the dulling of blades. When blades lose their sharpness, they can tear rather than cut grass, resulting in an uneven lawn. Dull blades can also put added stress on the engine, leading to decreased power and efficiency. Regular sharpening or replacement is essential for keeping the system in top shape.

Clogged or Damaged Belts

Another common problem is when the belts become worn, stretched, or clogged with debris. These belts are crucial for transferring power to the cutting components. A damaged or obstructed belt can cause inefficient power transfer, or even break, leading to a complete loss of functionality. Regularly inspecting and cleaning the belts helps avoid this issue.

Maintaining and Replacing Critical Components

Regular maintenance is essential to ensure that key components of your lawn equipment operate at their best. Over time, certain elements will naturally wear out due to constant use, requiring timely replacement. By staying proactive with maintenance and addressing issues early, you can prolong the life of the equipment and improve its performance.

Routine Inspections and Lubrication

Performing routine inspections and applying proper lubrication is a simple yet effective way to avoid common malfunctions. Components such as moving parts, spindles, and belts require consistent checks to ensure they are free from debris and operating smoothly. Lubrication helps reduce friction, preventing unnecessary wear and tear that can lead to breakdowns.

Replacing Worn Out Components

Eventually, some parts will need to be replaced, especially if they show signs of excessive wear or damage. Critical components like blades, belts, and pulleys are often the first to go. When replacing them, ensure that you select compatible replacements and install them correctly to maintain optimal functionality. Regularly replacing worn-out parts will prevent further damage to other components and keep the equipment working efficiently.

Choosing the Right Replacement Parts

When it comes to maintaining lawn equipment, selecting the correct replacement components is essential for ensuring smooth operation. Using parts that are not suitable or compatible can lead to further damage or inefficient performance. It is crucial to know the specifications of your machine and choose components that match both in size and functionality to keep everything running at peak efficiency.

Compatibility with Equipment Specifications

Before purchasing any replacements, ensure that the new components are compatible with the existing structure of your equipment. Check the manufacturer’s recommendations or consult a professional to verify that the components you select meet the necessary requirements. This will help avoid issues such as improper fit or poor performance after installation.

Quality and Durability Considerations

Opting for high-quality components is crucial for longevity and reliability. While aftermarket parts may offer a lower price, they may not always provide the durability or performance of original parts. Investing in durable, high-quality components ensures that your equipment functions properly and remains operational for a longer period of time, saving you money in the long run.