Maintaining your lawn care equipment is crucial for its long-term performance and efficiency. Understanding the various components of your machine allows you to identify any issues and address them quickly. Whether you’re a professional or a homeowner, knowing the key parts and how they function can make repairs simpler and more effective.

Effective maintenance begins with having a clear understanding of the specific elements that make up your equipment. Regular checks and replacements not only enhance the longevity of your machine but also ensure that it runs smoothly, saving both time and money. By learning the layout and connections of essential components, you’ll be prepared to tackle any challenges.

In this guide, we’ll break down the critical sections of your equipment and highlight how they contribute to optimal performance. Whether it’s wear and tear or mechanical failure, knowing what to look for is the first step toward effective troubleshooting and repair.

Understanding Lawn Equipment Components

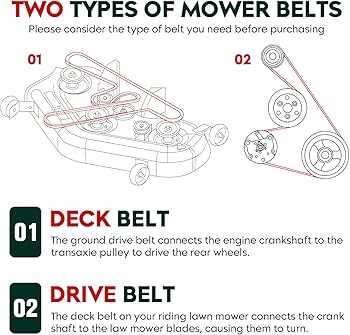

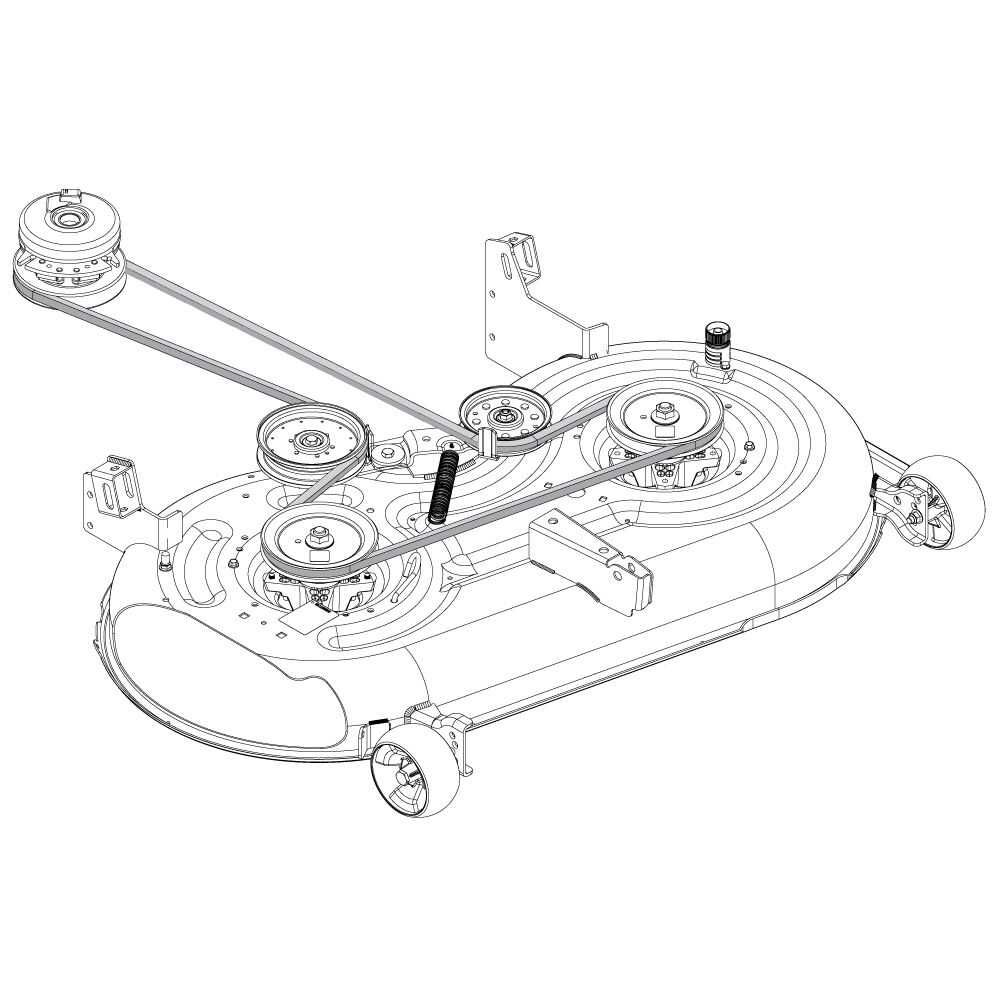

Each machine is made up of several interconnected elements, each playing a vital role in its operation. Understanding how these parts work together is essential for anyone looking to maintain or repair their equipment. These components, ranging from blades to belts, are designed to work in harmony, ensuring that the machine performs efficiently and reliably during use.

Key Elements and Their Functions

The core parts of the system include items such as the cutting mechanism, which determines the quality of the cut, and the drive components, which allow the machine to move effectively. Understanding the purpose of each element can help you troubleshoot any issues that arise. Regular inspection and maintenance are necessary to avoid breakdowns, ensuring the longevity of the machine.

Common Wear and Tear Areas

Some areas are more prone to wear due to constant use, such as the cutting blades, belts, and bearings. These parts may require more frequent replacement or adjustment to maintain optimal performance. Knowing where to check for signs of damage or fatigue can prevent costly repairs and keep the machine running smoothly for a longer time.

How to Replace Lawn Equipment Components

Replacing worn or damaged elements of your machine is essential for maintaining its performance. Knowing the right steps and tools for the job can make the process easier and more efficient. With proper guidance, you can ensure that each part is replaced correctly, helping to avoid further issues down the line.

Before beginning any replacement, make sure to disconnect the power source and ensure the machine is stable. Carefully examine the area around the component you need to replace, taking note of the connections and any fasteners. Using the right tools, remove the damaged or worn-out part and install the new one, ensuring it fits securely in place.

Once the new component is installed, double-check that all connections are tight and that the equipment functions as expected. Test the machine in a controlled environment to confirm everything is working properly before resuming regular use. Regular maintenance and timely replacement of key parts can help keep your equipment running smoothly for years.

Common Issues with Lawn Equipment

Even the most reliable machines can encounter problems after extensive use. These issues can range from minor inconveniences to more significant malfunctions that require immediate attention. Recognizing these common challenges early on can help prevent further damage and ensure that your machine continues to perform optimally.

Problems with Cutting Efficiency

One of the most common issues is a decline in cutting quality. Over time, blades may become dull or damaged, leading to uneven or poor cuts. Additionally, buildup of grass or debris around the cutting area can cause the equipment to struggle. Regular cleaning and blade sharpening can help maintain sharpness and prevent this problem.

Drive and Transmission Failures

Another frequent issue is with the machine’s drive system. Worn-out belts, damaged pulleys, or issues with the transmission can result in a lack of power or difficulty in movement. Keeping the drive components properly lubricated and checking for wear can minimize the chances of these failures occurring.