When it comes to maintaining outdoor machinery, a clear understanding of its components is essential. Knowing the arrangement of crucial elements within your equipment not only helps in performing effective repairs but also in regular maintenance. A well-organized system ensures that everything operates smoothly and efficiently, reducing downtime and extending the life of the machine.

Each piece of equipment consists of numerous parts, each with its specific function. By familiarizing yourself with their placement and role, you can diagnose issues with greater precision. A detailed guide that breaks down the various components makes it easier to identify what needs attention, whether it’s routine servicing or a more complex repair. With this knowledge, you can ensure that your machine remains in peak condition, ready to handle any task.

Proper maintenance is not just about replacing broken parts; it’s about understanding the flow of the system. By grasping how each element works together, you are empowered to spot potential issues before they become major problems. This proactive approach can save you time and money in the long run, allowing your equipment to perform at its best for years to come.

Understanding the Layout of Lawn Equipment Components

Every machine designed for outdoor tasks consists of a complex network of interconnected elements. The way these components are organized and linked determines the overall efficiency and functionality of the equipment. A clear understanding of their arrangement allows for better handling, maintenance, and troubleshooting when issues arise. Knowing the exact placement and role of each part can significantly improve your experience when servicing the machine.

Key Sections and Their Functions

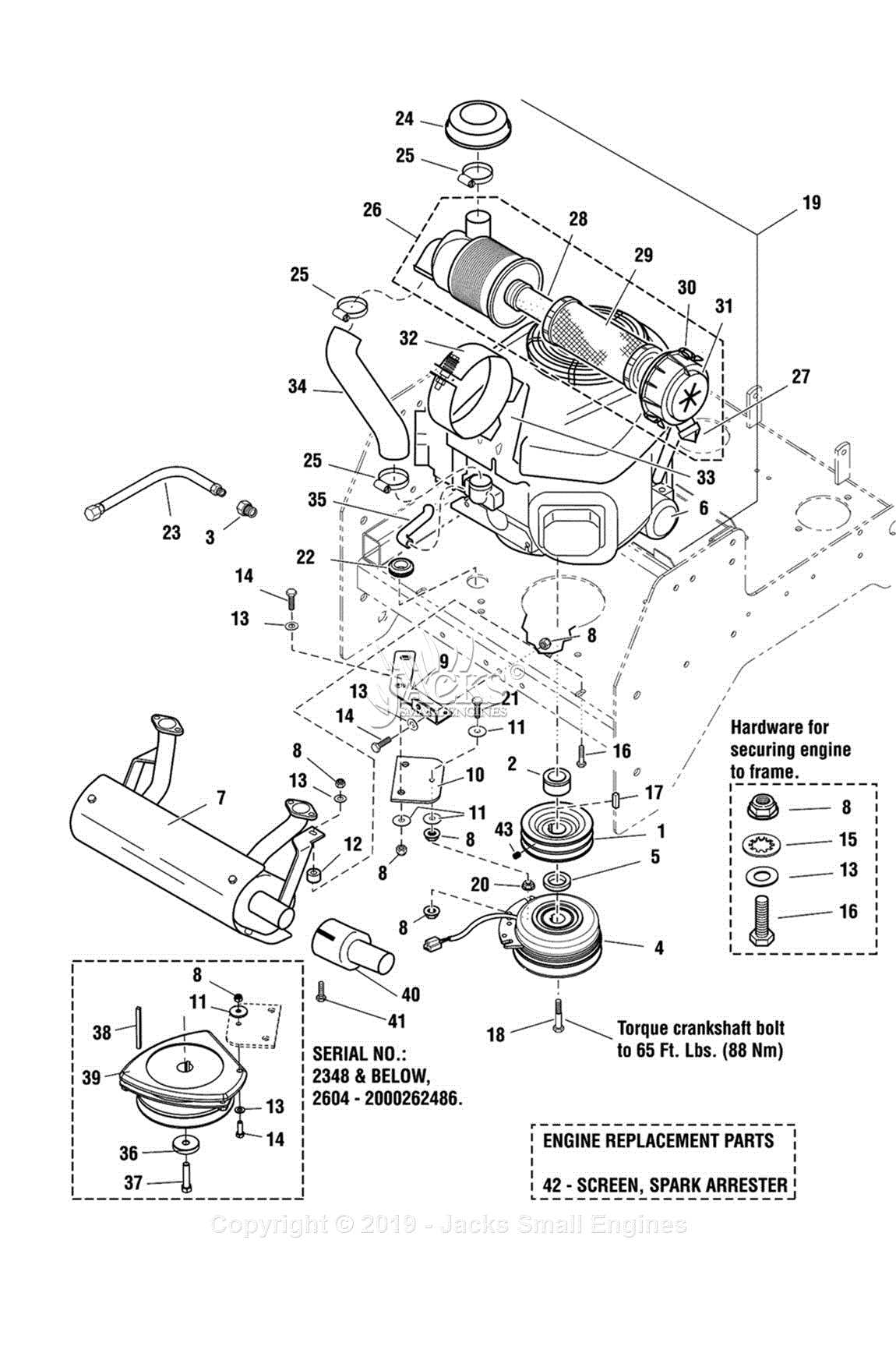

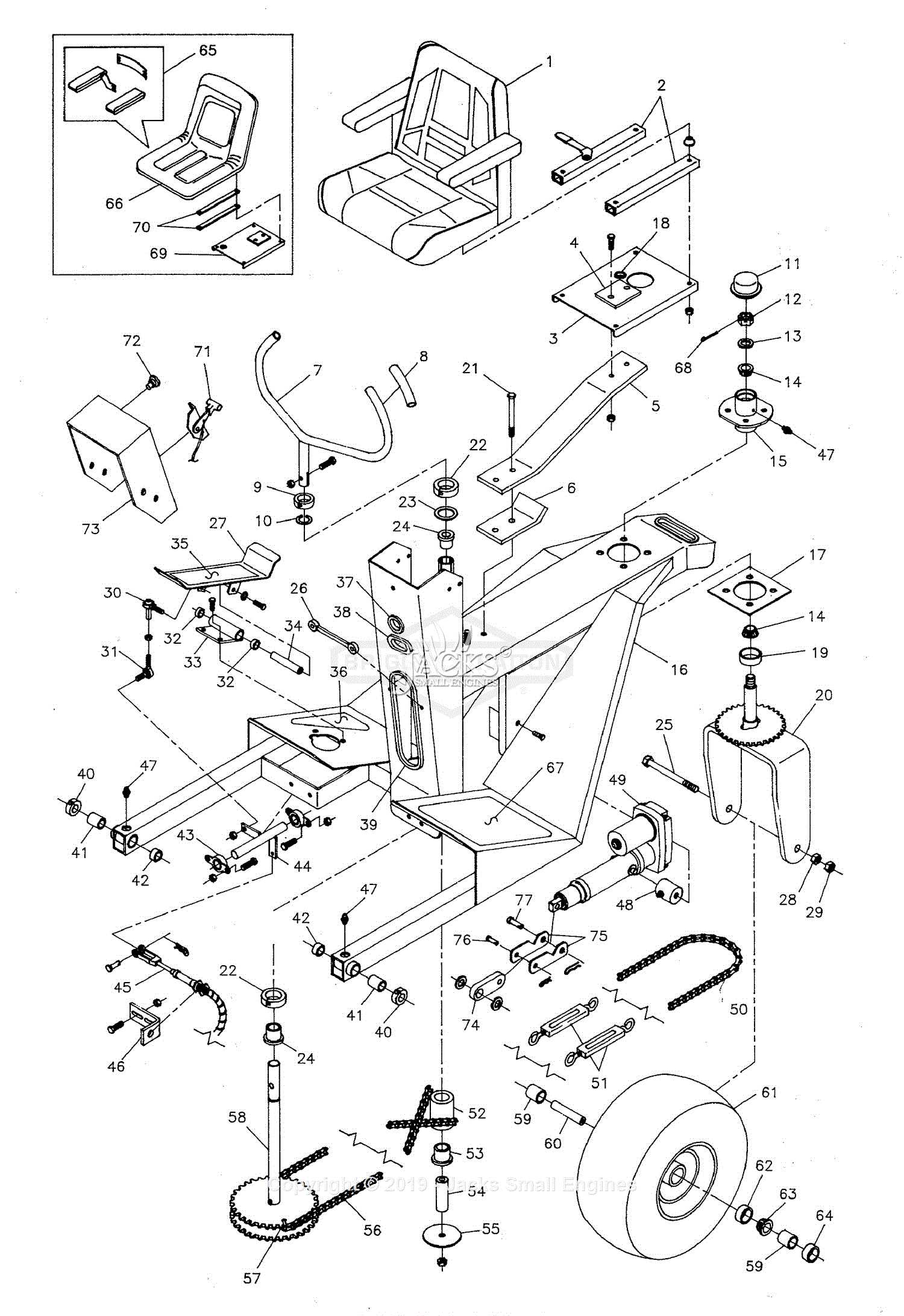

Machines typically feature several main areas that house critical components. These include the engine section, drive system, cutting mechanism, and control systems. Each section has its distinct role, but all are essential for the overall operation. The engine provides the power, while the drive system transfers this energy to the wheels or blades, allowing the machine to move or perform its primary function. Understanding how these sections work together gives you a clearer picture of the entire system.

Importance of Systematic Layout

A well-thought-out configuration ensures that each element is positioned for optimal performance and ease of access. For example, having key parts like filters, belts, and spark plugs in easy-to-reach areas can make routine inspections and repairs much more straightforward. Knowing where to find each part allows for quicker resolutions and minimizes unnecessary downtime. The systematic arrangement of components is not just about functionality; it’s also about durability and reliability over time.

How to Identify Key Components of Lawn Equipment

Identifying the essential elements of outdoor machinery is the first step in performing effective maintenance or troubleshooting. Each machine has specific components that serve critical roles in its operation, from the engine to the cutting system. Understanding these parts helps you know where to focus your attention during inspections and repairs, ensuring the equipment functions properly over time.

Start by familiarizing yourself with the overall structure of the machine. The engine is typically located at the front or center, providing the necessary power. Moving toward the rear, you’ll find the drive system, which channels that power to the wheels or blades, depending on the design. These two main systems are usually the primary focus, but it’s also essential to understand the auxiliary parts like fuel lines, belts, and filters that support the core functions of the machine.

Next, familiarize yourself with the specific role of smaller components, such as pulleys, bearings, and the ignition system. These often overlooked elements play a crucial part in ensuring smooth performance. Knowing where these parts are located and how they work together can save you time when diagnosing problems or performing preventative maintenance.

Step-by-Step Guide to Component Replacement

Replacing faulty or worn-out components is a crucial part of maintaining outdoor machinery. Whether you’re dealing with a broken belt, damaged filter, or worn blade, knowing the correct procedure ensures that the replacement is done safely and efficiently. This guide will walk you through the essential steps to identify, remove, and replace the faulty parts, restoring the machine’s full functionality.

First, ensure that the machine is turned off and disconnected from any power source. This is essential to avoid accidents during the replacement process. Next, gather the necessary tools and replacement components. Having everything ready before starting will make the process smoother and more efficient. Depending on the part you’re replacing, you may need specific tools such as wrenches, screwdrivers, or pliers.

Once you have all the tools in place, locate the faulty part by referring to the equipment layout. Carefully remove any covers or shields blocking access to the damaged area. Then, use the appropriate tools to remove the old component, ensuring that you do not damage surrounding parts in the process. Once the old part is removed, install the new one by carefully following the reverse steps, ensuring all connections are secure and tightened. Finally, test the machine to confirm that the replacement is successful and everything operates as expected.