Proper maintenance and repair of your lawn care equipment are crucial for ensuring long-lasting performance. Understanding the different components that make up the machine can help you identify potential issues and simplify the repair process. Having a clear reference to the various parts involved makes it easier to keep your equipment in optimal condition.

By familiarizing yourself with the layout and functionality of each section, you can quickly troubleshoot common problems. Knowing where each part fits and how it works together will provide you with the confidence to handle basic repairs without professional assistance. This guide offers an overview of essential components and practical advice for maintaining your equipment effectively.

Understanding the Lawn Equipment Components

Every piece of lawn care machinery consists of several crucial elements that work in harmony to deliver smooth operation. Understanding these components is key to ensuring the longevity and efficiency of your equipment. Each section has a specific function, contributing to the overall performance and reliability of the machine. A clear understanding of how these parts interact can help you troubleshoot issues and carry out maintenance tasks with ease.

Main Structure and Engine

The engine serves as the powerhouse of the equipment, driving the blades and other moving components. It is essential to know the basic engine components, such as the spark plug, fuel system, and cooling system. These elements work together to provide consistent power, and maintaining them is crucial for preventing breakdowns. Regular checks on oil levels and spark plug conditions are simple yet effective ways to keep the engine running smoothly.

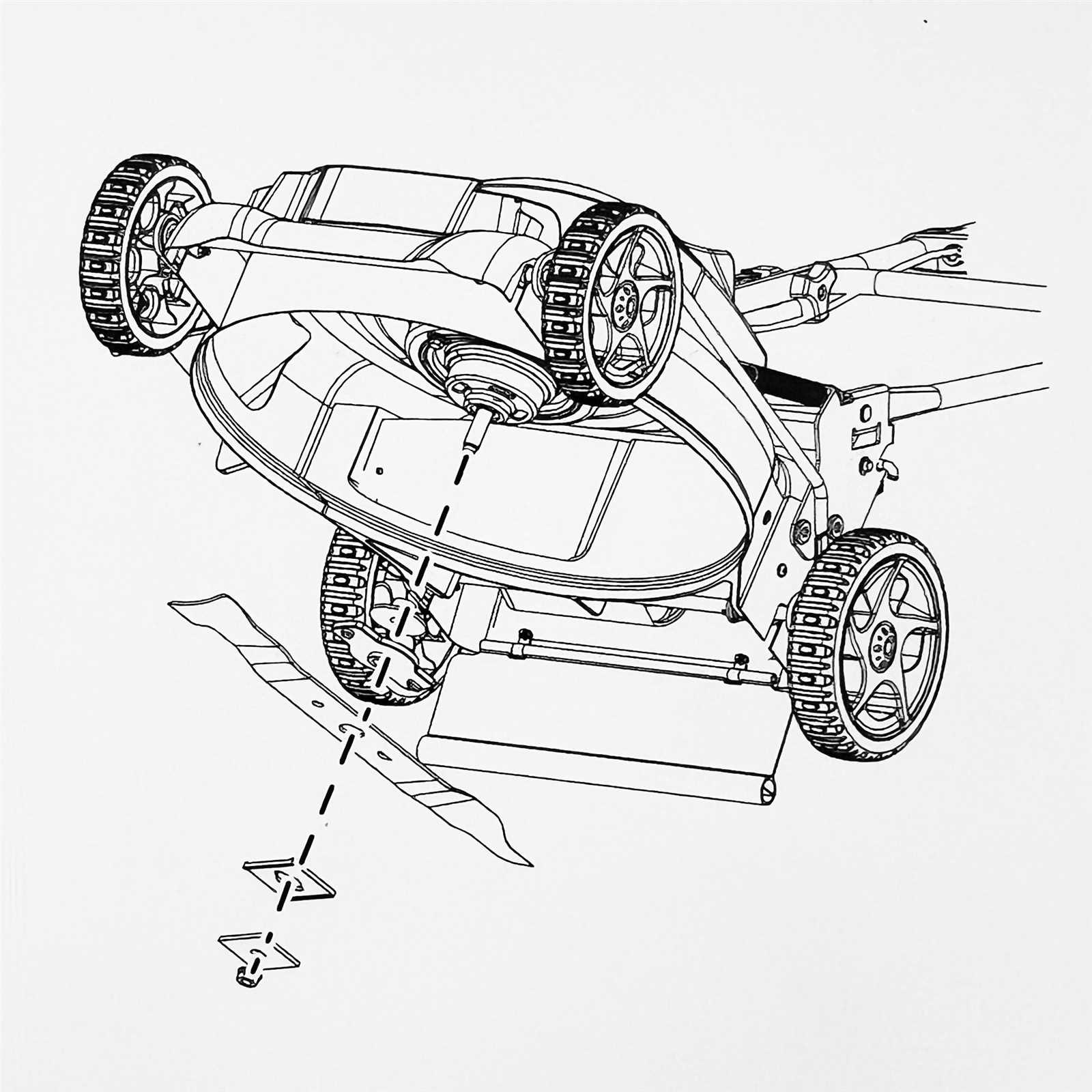

The cutting mechanism plays a vital role in the performance of your equipment, as it directly affects the quality of the job. This includes the blades, cutting deck, and associated components like the belt and pulley system that transfer motion from the engine to the cutting blades. A thorough understanding of how these parts interact allows for proper alignment, sharpness, and balance, contributing to optimal cutting performance. Similarly, the drive system, which powers the wheels, ensures smooth movement across the lawn. Routine inspections of the belts and wheel mechanisms are essential for maintaining mobility and precision.

Key Parts for Lawn Equipment Repair

To effectively maintain and repair your lawn care machine, it is important to familiarize yourself with the essential components that may require attention over time. These components are integral to the overall functionality, and recognizing when they need adjustment or replacement can save both time and money. Regular inspection of these parts ensures your equipment operates efficiently and extends its lifespan.

The engine, for instance, plays a pivotal role in powering the entire system. Ensuring it runs smoothly by checking fuel lines, spark plugs, and air filters is vital. Additionally, the cutting system, which includes the blades, drive belt, and pulley system, must be kept in good condition to guarantee consistent performance. Lastly, the wheel and drive mechanisms require occasional maintenance to avoid unnecessary wear and ensure smooth movement across your lawn.

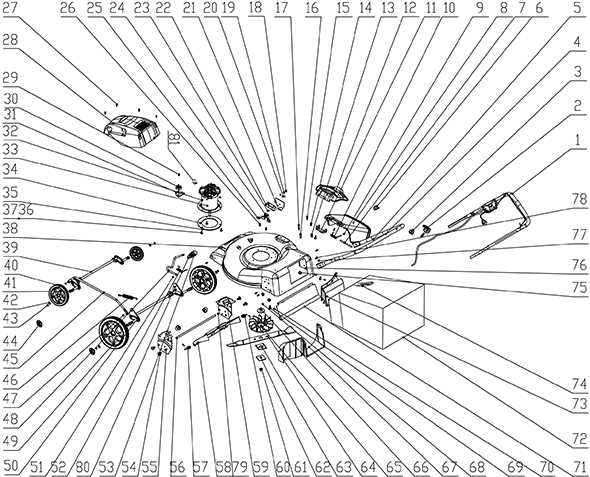

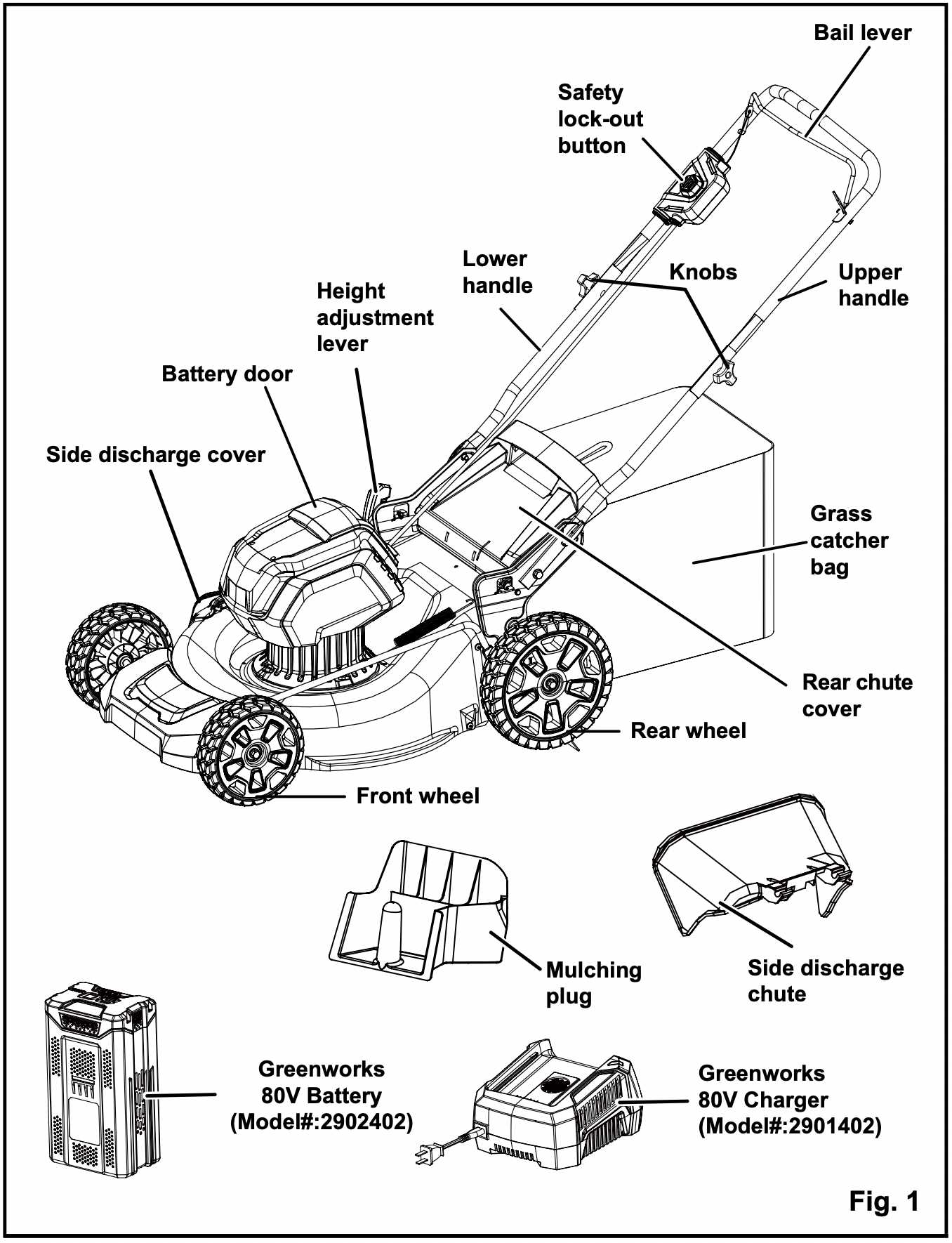

How to Use the Components Layout Effectively

Utilizing a layout of the equipment’s components can greatly simplify maintenance and repair tasks. This visual guide helps you identify each part’s function and placement within the machine. By referring to this guide, you can easily locate any worn-out or damaged parts that need attention, ensuring quicker and more precise repairs.

To use the layout effectively, start by familiarizing yourself with the overall structure of the machine. Pay attention to how the components are connected and understand their role in the overall operation. When troubleshooting, refer to the diagram to match the malfunctioning part with its visual counterpart. This will allow you to focus on specific areas, eliminating unnecessary steps and reducing repair time.