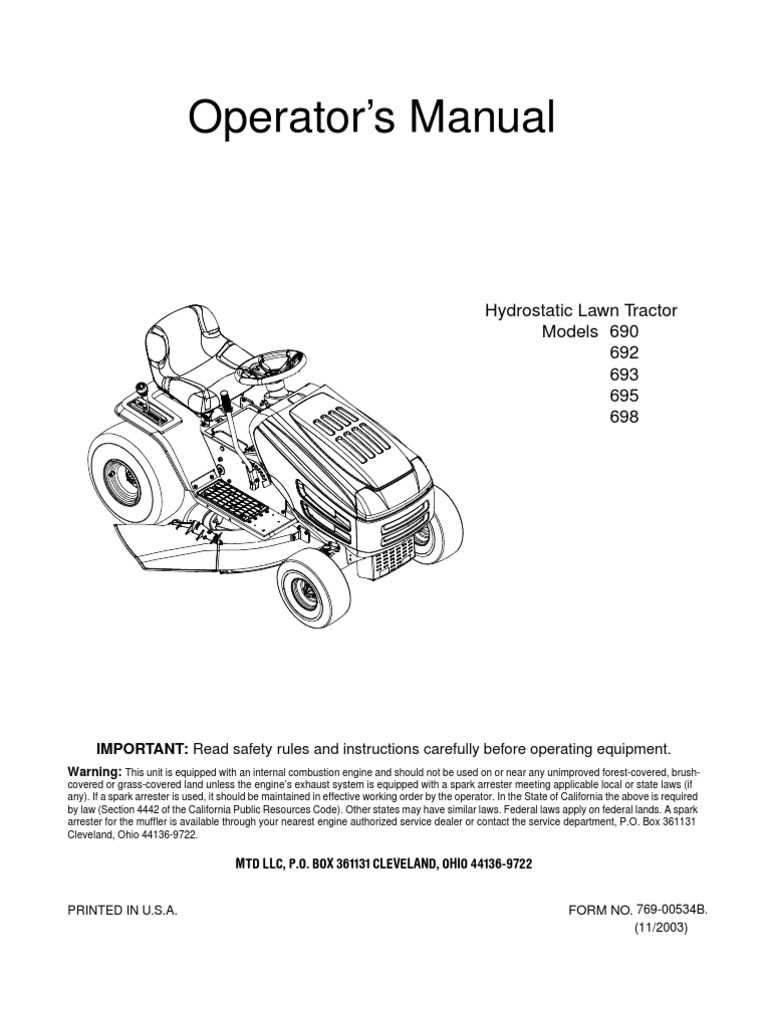

Properly maintaining your outdoor machinery is essential for keeping it in peak condition and ensuring its longevity. Whether you’re a professional landscaper or a homeowner, knowing the layout of the key components in your equipment can save time and money in repairs. A clear understanding of how each part functions and interacts is crucial for efficient operation.

In this guide, we will explore the various elements that make up a typical lawn care machine. You’ll learn how to identify different sections, understand their roles, and recognize signs of wear and tear. Regular maintenance, combined with the right knowledge, will help prevent costly breakdowns and improve performance throughout the season.

With the right approach, tackling maintenance tasks becomes straightforward. From routine checks to more complex repairs, familiarity with the structure of your device is the first step towards effective upkeep. Whether you’re replacing a simple belt or servicing more intricate systems, having the right information on hand is vital for a smooth experience.

Understanding Lawn Equipment Components

To effectively operate and maintain your outdoor machine, it is essential to have a solid understanding of its internal elements. Knowing how each part contributes to the overall function of the equipment allows for more efficient troubleshooting and maintenance. A well-rounded grasp of the key features ensures that repairs are easier and downtime is minimized.

Most outdoor machines have several critical components that work together seamlessly to achieve optimal performance. From the engine to the cutting system, each section serves a specific purpose and requires regular inspection. Familiarity with these individual parts can help you identify potential issues early on, before they become more complicated and costly to fix.

Whether you’re dealing with the drive system, the transmission, or the cutting deck, each component plays a role in delivering consistent results. Understanding the mechanics behind each of these sections will give you the confidence to handle routine maintenance and address problems when they arise.

Key Parts for Efficient Lawn Maintenance

Maintaining a well-kept lawn requires more than just regular grass cutting. It involves understanding and caring for the different sections of your equipment that make the process easier and more effective. A few core components are especially important for ensuring your tool performs at its best, leading to better results and fewer repairs.

Critical Components for Smooth Operation

Key systems like the engine, transmission, and cutting deck all work in tandem to provide the power and precision needed for smooth performance. Regular inspection and maintenance of these areas can significantly extend the lifespan of the equipment and enhance its overall efficiency.

Wear and Tear: Monitoring Common Areas

Some parts experience more wear due to constant usage, including the belts, blades, and tires. Keeping these areas in check can prevent unexpected breakdowns and ensure the machine operates at full capacity. Regularly replacing worn-out components is essential for smooth operation and a clean finish.

| Component | Role | Maintenance Tips |

|---|---|---|

| Engine | Power source for operation | Change oil regularly and check for leaks |

| Transmission | Transfers power to the wheels | Inspect for smooth shifting and proper lubrication |

| Cutting Deck | Provides the cutting action | Clean after use and sharpen blades as needed |

| Belts | Transfers power from the engine to moving parts | Check for cracks or fraying and replace if damaged |

| Tires | Provide traction and stability | Inspect for wear and ensure proper air pressure |

How to Identify Lawn Equipment Components

Knowing how to recognize the various elements of your outdoor equipment is essential for efficient operation and troubleshooting. Understanding the key sections and their functions allows for quick diagnosis when something goes wrong. Whether you’re inspecting for wear or replacing a faulty piece, identifying each part accurately is the first step toward proper maintenance.

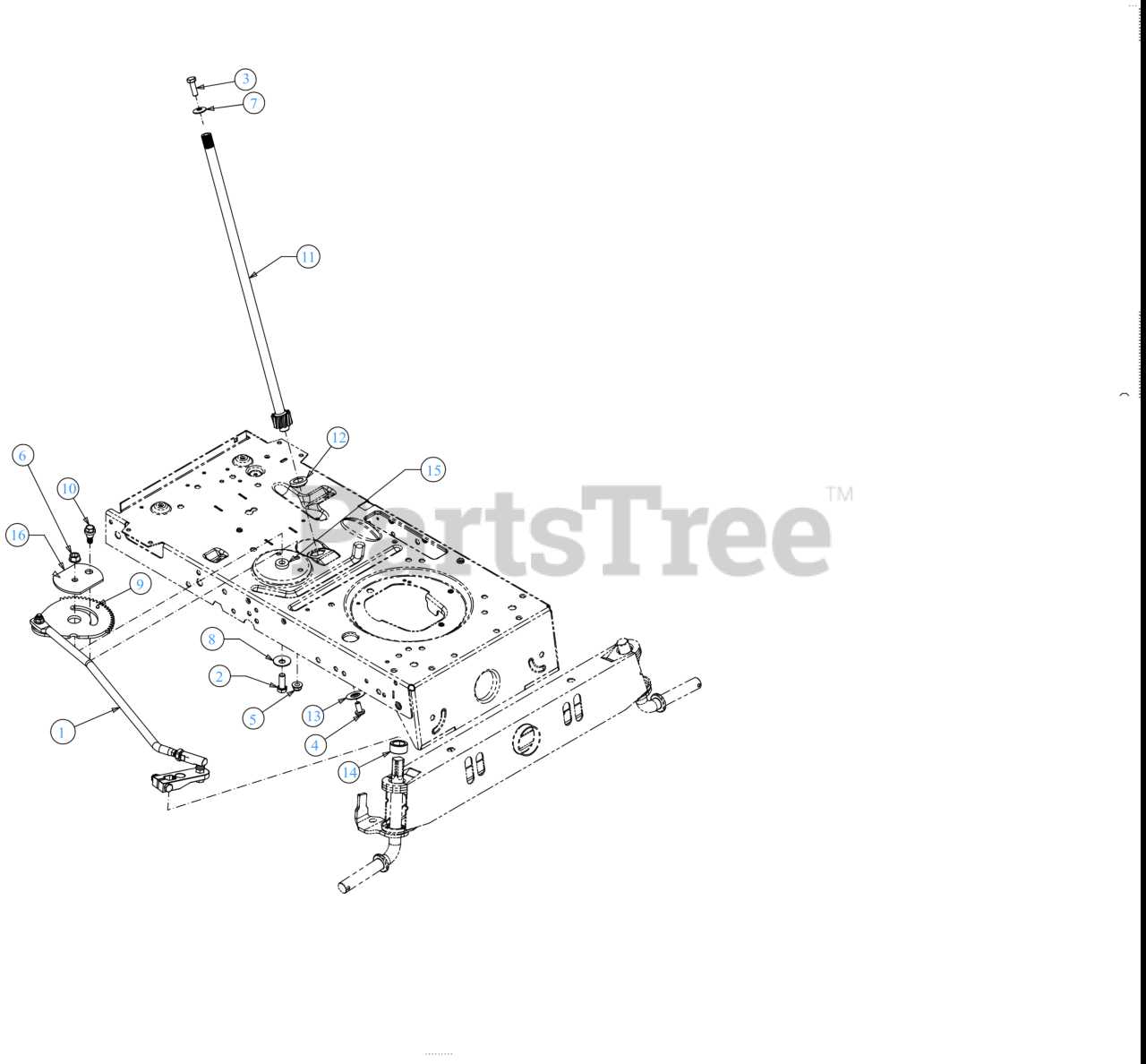

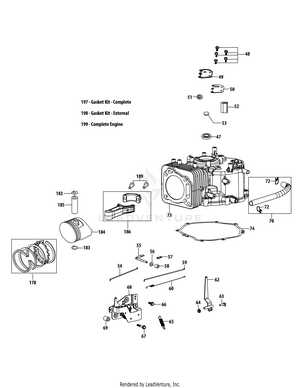

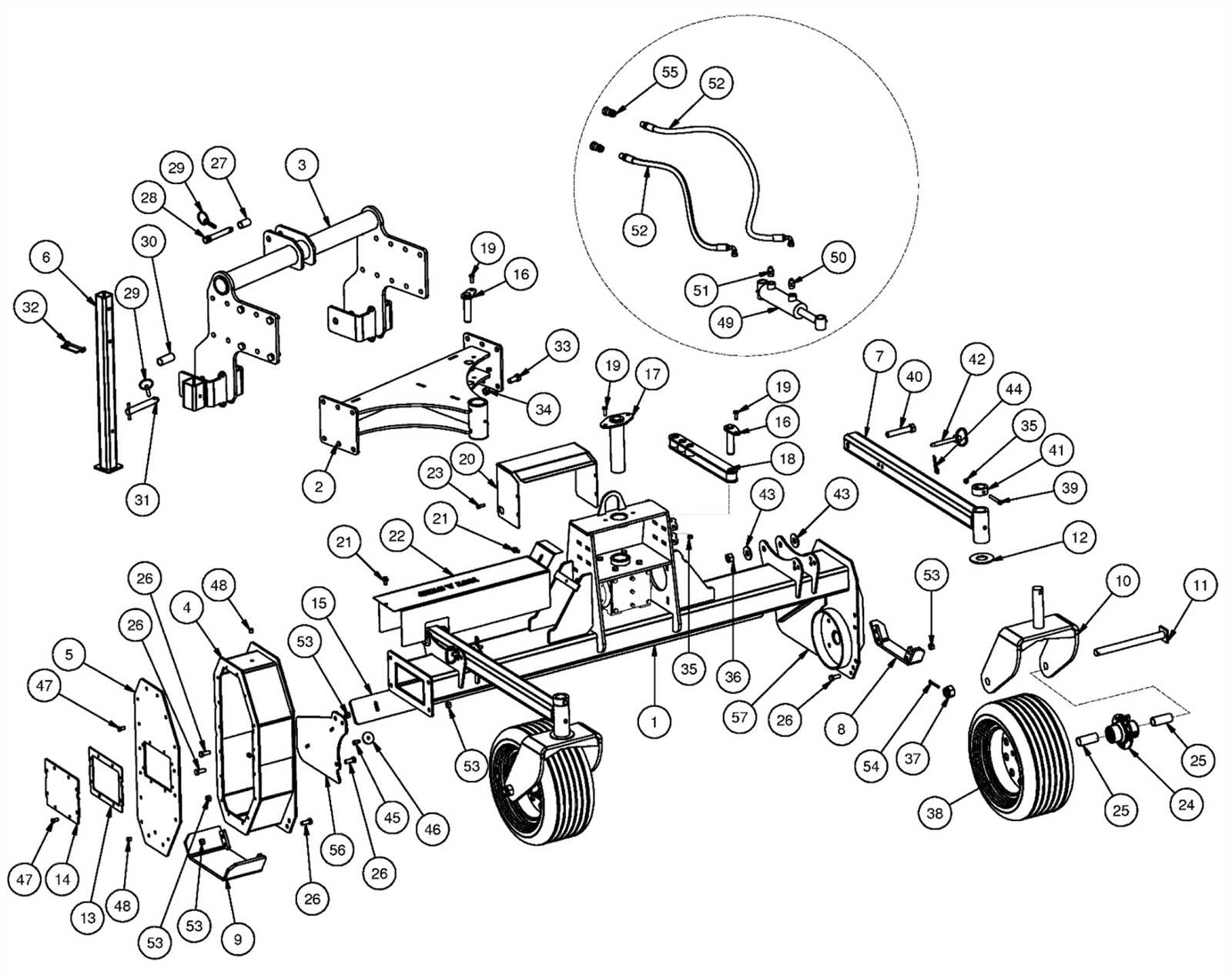

Visual Inspection and Labeling

The easiest way to start identifying different sections is through a visual inspection. Look for any labels or serial numbers, which can help you cross-reference parts with the user manual or an online reference. Components such as the engine, transmission, and cutting mechanism are typically labeled, making them easier to spot. Pay attention to any markings that indicate model-specific details.

Utilizing a Reference Guide

If you’re unsure about the exact function of a particular piece, a reference guide or user manual can provide in-depth descriptions of each part. These resources often feature labeled diagrams and part numbers that make identification easier. Additionally, online resources, such as manufacturer websites or repair forums, can offer valuable insight into identifying and sourcing replacement components.

For accurate identification, ensure you have the correct model information, as some systems may differ slightly depending on the version. Once you know the part number or description, you can more effectively proceed with repairs or replacements.

Recognizing Common Wearable Components

Many components of your lawn care equipment experience regular wear due to constant use. Identifying these parts early is essential to maintaining efficiency and preventing breakdowns. By recognizing which sections are prone to wear and tear, you can stay ahead of potential issues and replace worn-out components before they cause significant damage.

The most common wearable parts include belts, blades, tires, and filters. These elements play a crucial role in the overall performance of your machine and should be monitored regularly. Over time, they may become less effective or even fail entirely, so it’s vital to keep an eye on their condition.

For example, belts are essential for transferring power between different parts, but they can stretch or crack over time. Similarly, blades may become dull or damaged, resulting in uneven cuts. Tires may lose air or show signs of tread wear, which can affect traction. Filters, especially air and fuel filters, can clog and reduce engine performance if not replaced periodically.

Maintaining and Replacing Lawn Equipment Components

Proper maintenance is key to extending the lifespan of your outdoor machinery. Keeping an eye on essential systems, regularly replacing worn components, and performing necessary repairs can ensure that your equipment continues to operate efficiently. Knowing when and how to replace parts is as important as the maintenance routine itself.

Regular maintenance tasks help prevent major breakdowns and keep the machine running smoothly. Some components need to be replaced more frequently than others, depending on usage and the conditions in which the equipment operates. By following a routine maintenance schedule, you can catch issues early and avoid costly repairs.

Essential Maintenance Tasks

- Change the oil and check for leaks regularly to maintain engine health.

- Inspect belts for signs of wear and replace them if they show signs of cracking or stretching.

- Sharpen or replace cutting blades to ensure clean, even cuts.

- Clean or replace air and fuel filters to maintain engine performance.

- Check tire pressure and look for any damage to ensure proper traction.

When to Replace Components

There are clear signs that indicate when it’s time to replace specific components. For example, belts that slip or make noise, blades that don’t cut effectively, or tires that lose air quickly should be replaced immediately to avoid further damage. Additionally, replacing filters at regular intervals can prevent poor engine performance and increase fuel efficiency.

By addressing maintenance tasks on time and replacing damaged components, you can keep your equipment in optimal condition, ensuring its reliability throughout the season.