Maintaining and repairing your lawn equipment requires understanding its internal components and how they work together to achieve optimal performance. This guide provides a detailed look at the essential elements involved in the setup, repair, and maintenance of your machine.

By familiarizing yourself with the various components and their functions, you’ll be able to handle common issues and ensure the longevity of your equipment. Proper identification and understanding of these elements are key to keeping everything running smoothly.

Efficient maintenance can help you avoid costly repairs and enhance the overall effectiveness of your machine. Whether you’re tackling basic maintenance or addressing more complex issues, knowing the system inside and out is crucial for success.

Understanding the 48-Inch Lawn Equipment System

For optimal operation, it’s essential to grasp how the different components of your machine interact. Each part contributes to the overall functionality, ensuring smooth and efficient performance during use. This system relies on precise alignment and proper maintenance to avoid breakdowns.

Several key elements are involved in the overall function, each serving a unique purpose. Understanding how they work together can help with troubleshooting and improving your machine’s efficiency. Regular inspections and maintenance are important to detect issues early.

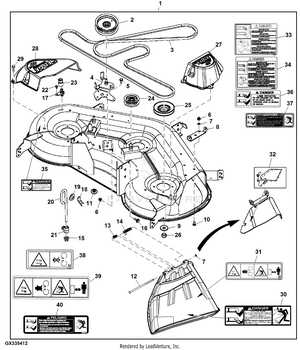

- Frame: The backbone of the system, supporting all other components.

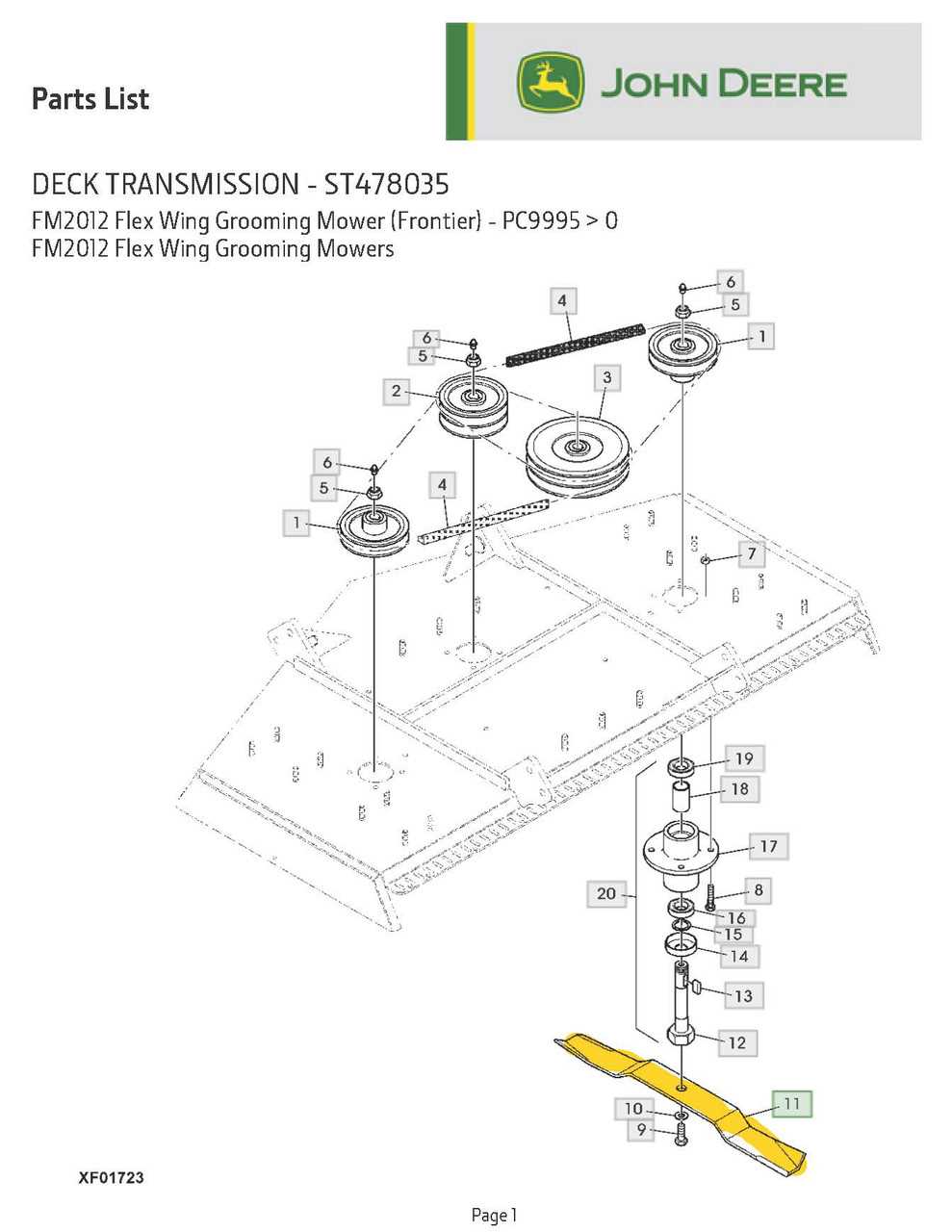

- Spindles: Responsible for driving the blades, allowing them to rotate effectively.

- Blades: These cut the grass, and their sharpness and positioning directly affect the quality of the cut.

- Belts: Transfer power from the engine to the spindles and other moving parts.

Knowing the roles of each element within this system can help users identify what may be malfunctioning, as well as how to replace or adjust each part for improved performance. Taking the time to understand each component will ensure that your equipment lasts longer and operates at peak efficiency.

Essential Components for Maintenance and Repair

Proper upkeep and timely repairs of your equipment are crucial for maintaining its performance and longevity. To ensure everything runs smoothly, it’s important to regularly check and replace specific components that experience wear and tear. These elements directly affect the efficiency of the system and need attention to avoid costly issues down the line.

Critical Components to Inspect

Several key components play a vital role in the smooth operation of the machine. Regularly inspecting and replacing these parts ensures consistent performance and minimizes downtime:

- Belts: These transfer energy from the engine to moving parts. Over time, belts can wear down and slip, leading to performance issues.

- Blades: Sharp, properly aligned blades are essential for an even cut. Dull or damaged blades can affect the quality of the work and strain the system.

- Spindles: These parts allow the blades to rotate. They are critical for the effective functioning of the cutting mechanism and require lubrication and periodic checks for wear.

Additional Items to Monitor

Besides the core components, it’s also important to keep an eye on other less obvious parts. Regular maintenance of these elements helps prevent unexpected breakdowns:

- Frame: The main structure of the equipment that supports all other parts. A damaged frame can lead to misalignment of moving elements.

- Bearings: Bearings reduce friction between moving parts and need regular greasing or replacement to ensure smooth motion.

By staying proactive with the care of these essential components, you’ll not only extend the lifespan of your equipment but also enhance its overall performance.

Common Issues with Lawn Equipment Components

Even the best-maintained machines can face issues due to the wear and tear of their moving parts. Understanding the common problems that arise in these systems allows for quicker identification and resolution, minimizing downtime and avoiding more significant damage. Regular inspection and prompt action are key to addressing these issues before they become costly repairs.

Worn or Damaged Blades

One of the most common problems with lawn equipment is worn or damaged blades. When blades become dull, they fail to provide a clean, even cut. Over time, this can stress the engine and other components, reducing overall efficiency. Additionally, cracks or chips in the blades can lead to imbalanced cutting, affecting the quality of the job.

Slipping Belts and Misaligned Spindles

Belts play a crucial role in transmitting power from the engine to the necessary components. If belts become too loose or worn, they can slip, causing a loss of power and inefficient operation. Misaligned or damaged spindles can also cause issues with blade rotation, leading to irregular cuts or even further damage to other parts.

By identifying and addressing these common problems early, you’ll improve the performance and longevity of your equipment. Regular checks and maintenance can prevent these issues from escalating into more significant and costly repairs.

How to Identify and Replace Components

Recognizing when components need attention and knowing how to replace them is essential for maintaining the functionality and longevity of your equipment. Regular inspections allow you to catch wear and tear early, while a good understanding of how to replace faulty elements ensures smooth operation. Proper identification is the first step in avoiding further damage and reducing repair costs.

Start by examining each component for visible signs of wear, such as cracks, rust, or fraying. Once you’ve identified the damaged or worn parts, ensure that you purchase the correct replacements, as using the wrong components can lead to further complications. Be sure to check the equipment manual or consult the manufacturer’s recommendations for accurate specifications.

Replacing the faulty components typically involves a few key steps: disconnecting power sources, removing the damaged part carefully, and installing the new component securely. For some parts, like belts or spindles, regular lubrication or adjustments may also be necessary for optimal performance.

By taking the time to properly identify and replace faulty elements, you can keep your equipment in peak condition, saving both time and money in the long run.

Step-by-Step Guide to Lawn Equipment Assembly

Assembling your lawn equipment correctly is crucial for ensuring smooth operation and optimal performance. Proper assembly ensures that each component fits together perfectly, reducing the likelihood of malfunctions or inefficiency. Follow these steps carefully to assemble the system correctly and avoid potential issues.

Preparation and Inspection

Before beginning the assembly process, take the time to gather all necessary components and tools. Ensure that you have everything you need, including fasteners, brackets, and any lubricants required. Inspect each part for any damage or wear before starting. It’s essential to make sure all elements are in good condition to prevent future problems.

Assembly Process

Start by positioning the frame and securing the essential components, such as the rotating mechanism and supporting arms. Align the spindles properly and ensure that the moving parts are securely attached to the main structure. After connecting the critical elements, install the blades, ensuring they are properly aligned and tightened. Pay special attention to any moving parts and ensure they can operate freely without obstruction.

Final Adjustments are equally important for ensuring that everything is functioning as it should. Once the assembly is complete, check for any loose components and tighten them. Lubricate the moving parts to ensure smooth operation. Finally, perform a brief test run to ensure everything is working properly.

By following this step-by-step guide, you can ensure that your lawn equipment operates efficiently and is ready for use.