Understanding the structure of your outdoor machinery is essential for keeping it running smoothly. A well-maintained system not only ensures optimal performance but also extends the life of your equipment. Whether you’re a hobbyist or a professional, knowing the key elements that make up your machine helps in troubleshooting and repairs.

The intricacies of the cutting system are often overlooked but are crucial for effective operation. Familiarity with the various components allows for quicker identification of issues and a more efficient approach to maintenance. From the blades to the drive mechanisms, each part plays a role in achieving a precise cut and minimizing wear over time.

In this guide, we’ll delve into the essential components of a common grass-cutting setup. With a focus on how each element interacts, you’ll be better equipped to handle any maintenance tasks that may arise. Whether you’re replacing a worn piece or simply performing routine checks, having this knowledge will enhance your experience with lawn equipment.

Understanding the Lawn Equipment Cutting System

Every piece of outdoor machinery designed for cutting grass contains several interconnected components that work together to achieve efficient and precise performance. Knowing how these elements fit and operate in unison is essential for anyone maintaining or repairing such equipment. Proper understanding ensures that your machine continues to run smoothly and lasts longer, reducing downtime and costly repairs.

Key Components and Their Functions

The cutting mechanism consists of various elements, each performing a specific task. From the rotating blades to the pulleys and belts that drive them, every part has an essential function. The blades are the most noticeable components, responsible for trimming the grass to the desired height. However, the supporting elements such as the belt system, spindles, and tension springs ensure smooth operation and consistent performance.

How Components Interact for Optimal Performance

The efficiency of a grass-cutting system depends on how well the components work together. The belts drive the spindles that turn the blades, while the tension springs maintain the correct pressure for proper blade movement. Each component needs to be in good condition, and proper alignment is crucial for smooth operation. Understanding these relationships helps in diagnosing issues and making informed decisions about when and how to replace worn-out parts.

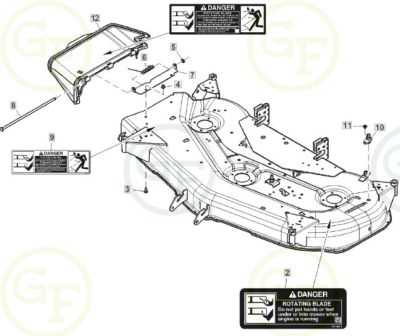

Components of the 54 Inch Mower Deck

Understanding the various elements that make up the cutting assembly is key to ensuring the efficiency of your outdoor equipment. Each component plays a specific role in ensuring smooth operation and achieving precise results. These parts work together to provide reliable performance, whether for routine mowing or larger landscaping projects.

Blades and Their Functionality

The most prominent part of any cutting system is the blades, which are responsible for actually trimming the grass. Made of durable steel, these blades are designed to withstand the pressure of cutting thick grass and debris. Their sharp edges must be maintained to ensure clean cuts, and the blades should be replaced when they become dull or damaged. Properly functioning blades are crucial for maintaining a neat and professional-looking lawn.

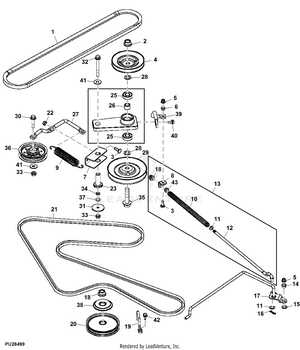

Drive System and Pulley Mechanism

The drive system powers the blades and is comprised of pulleys, belts, and spindles. The belts transfer power from the engine to the cutting blades, and the pulleys guide the movement of the belts, ensuring that the system operates efficiently. The spindles, which are connected to the blades, rotate them as the power is transmitted. Proper tensioning of the belts and maintaining the pulleys is essential to ensure that the blades spin at the correct speed and the cutting system operates without interruption.

How to Maintain Your Lawn Equipment

Proper maintenance is essential for keeping your outdoor machinery running at peak performance. Regular care not only ensures efficient operation but also extends the lifespan of the components. By staying on top of routine maintenance tasks, you can avoid costly repairs and maintain a clean, well-kept lawn throughout the season.

Inspecting and Sharpening the Blades

The cutting blades are subject to wear and tear, so regular inspection is vital. Check for any nicks, chips, or bends in the blades that could affect their performance. Dull blades can result in uneven cuts, so sharpening them is essential for a clean finish. If sharpening isn’t enough, replacing the blades is often necessary to maintain efficiency.

Checking and Adjusting the Belts

Belts that drive the cutting system should be inspected regularly for wear, cracks, or fraying. A worn-out or loose belt can reduce the effectiveness of the entire cutting assembly. Ensure the belts are properly tensioned and aligned to avoid unnecessary strain on the system. Replace any damaged belts to keep the machine running smoothly.