Maintaining your lawn machinery is essential for optimal performance and longevity. Whether you’re a professional landscaper or a homeowner, understanding the intricate details of your equipment can make a significant difference in its efficiency. This guide will provide you with valuable insights into how to interpret visual references and identify the key components that keep your equipment running smoothly.

Knowing the structure and function of the various elements is crucial for troubleshooting and replacement. Each machine has its unique setup, and by recognizing the parts and their roles, you can easily address any issues that arise. This knowledge helps ensure that you can perform repairs and maintenance with confidence and accuracy.

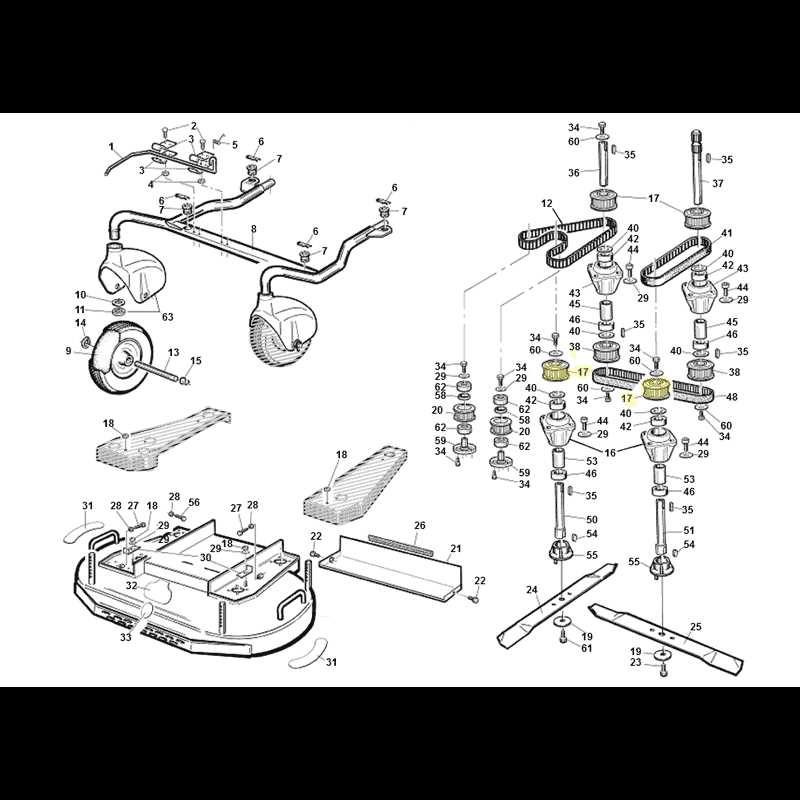

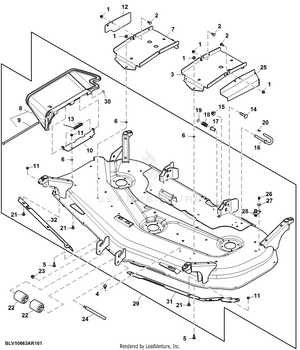

By referring to detailed illustrations, you’ll gain a clear understanding of the machinery, making it easier to assemble, disassemble, or replace components as needed. This approach not only saves time but also minimizes the risk of mistakes during repairs.

Understanding Lawn Equipment Structure

Every lawn machine consists of multiple components working together to achieve the desired performance. By understanding how these parts interact, users can better manage their equipment, ensuring that it functions effectively over time. Recognizing the key elements and their roles helps in performing routine maintenance, troubleshooting issues, and making necessary repairs.

The key to proper functioning lies in understanding the configuration of the machinery. Components like the blades, housing, and pulleys each have specific functions that contribute to the overall operation. When these parts are in optimal condition, the equipment operates smoothly, providing an even cut and avoiding unnecessary strain on the engine.

To maintain your machinery effectively, it’s crucial to have a comprehensive view of how the components are assembled. With the right knowledge, repairs become more manageable, and the lifespan of the machine is extended. Proper inspection and timely replacement of damaged parts ensure that your equipment continues to perform at its best season after season.

Key Components of the Lawn Equipment

To ensure efficient operation, every machine relies on a set of essential components, each with its specific function. These elements work together to achieve optimal performance and deliver the expected results. By familiarizing yourself with these parts, you can better understand how the equipment operates and how to maintain it properly.

Blades and Cutting Mechanism

The cutting mechanism is at the heart of any lawn machine. It consists of sharp blades designed to trim grass evenly and efficiently. Proper alignment and sharpness are crucial for achieving a clean cut. Regular maintenance ensures that the blades stay sharp and free from debris, preventing strain on the engine and promoting a smooth operation.

Transmission and Pulley System

The transmission system, along with the pulleys, plays a critical role in transferring power from the engine to other components, such as the blades. This system ensures that the speed and rotation are controlled, allowing for precise adjustments. Regular inspection of these parts helps maintain proper functionality and prevents unnecessary wear.

How to Use the Parts Diagram Effectively

Visual references are invaluable when it comes to understanding the layout of complex machinery. By studying detailed illustrations, you can easily identify the components and their placement. This method not only simplifies repairs and maintenance but also helps in understanding how each part contributes to the overall performance of the equipment.

To use a reference image effectively, start by familiarizing yourself with the general layout and the names of the components. Pay attention to the labels and numbers that correspond to each part. This will make it easier to locate specific pieces when you need to replace or inspect them. Take your time to carefully analyze each section before moving on to the next.

When troubleshooting or assembling, cross-reference the diagram with the actual components on your machine. This practice ensures that you are working with the correct part and installation method. Additionally, a well-understood reference guide can prevent errors, helping to save time and avoid unnecessary mistakes during maintenance.