Maintaining outdoor machinery requires a clear understanding of its individual components and how they fit together to ensure optimal performance. A well-functioning system is the key to efficient operation, reducing wear and tear and extending the life of the equipment. Knowing each part’s role allows users to diagnose issues quickly and keep the equipment running smoothly.

Recognizing the different pieces that make up these tools is essential for both regular maintenance and repairs. Each part has a unique function, and understanding its place in the overall assembly helps prevent mistakes when assembling or disassembling. Whether you’re looking to replace a specific piece or conduct routine checks, it’s important to have a clear idea of the system’s layout.

By exploring how each section interacts with others, users gain confidence in handling their machinery. This approach not only enhances efficiency but also minimizes the risk of damage, ensuring that all components work together seamlessly for long-lasting reliability.

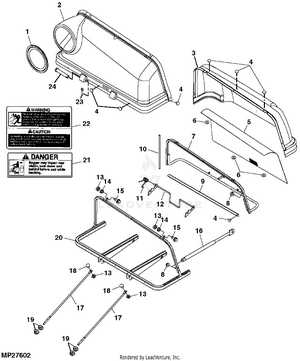

Essential Components of X500 Mower Deck

Every outdoor tool designed for grass cutting relies on a series of integral components that function together to ensure smooth operation. These elements work in harmony to provide power, stability, and precision. Recognizing the importance of each individual part makes maintenance easier and more effective, reducing the risk of mechanical failure during operation.

The system consists of several core pieces, each performing a distinct role, from power delivery to height adjustment. The rotating mechanism is one of the most vital, responsible for ensuring even trimming. Equally important are the supporting sections that stabilize and maintain the proper alignment, allowing the cutting area to function consistently throughout use.

Understanding how these components interact helps in troubleshooting and determining the necessary steps for maintenance. It also allows users to identify which pieces need attention or replacement, ensuring the equipment operates at peak efficiency.

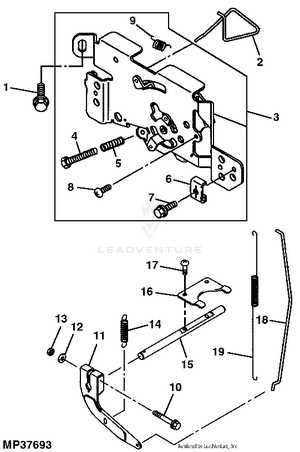

Understanding the Mower Deck Assembly

Every outdoor machine used for grass trimming is built upon a well-organized assembly that ensures efficient and reliable performance. The structure consists of interconnected elements that each serve a specific function to guarantee precision and durability. By understanding how each section contributes to the overall operation, users can ensure smoother maintenance and effective repairs when necessary.

The assembly includes several key components that work together, from the base structure to the rotating sections responsible for cutting. These elements must be properly aligned and calibrated to achieve optimal performance. Any misalignment or wear in one part can lead to uneven operation, impacting the overall quality of the task at hand.

Recognizing how these components are assembled is essential for anyone who needs to disassemble or repair the equipment. It helps in identifying the source of issues and ensures that all pieces are reassembled in the correct order for smooth functioning. This knowledge is crucial for prolonging the lifespan of the equipment and ensuring it operates efficiently over time.

Maintenance Tips for X500 Parts

Regular upkeep is essential to ensure the longevity and performance of your outdoor equipment. Proper care and attention to individual components can prevent premature wear and costly repairs. By following some basic maintenance guidelines, you can extend the life of your machine and ensure it continues to function efficiently for years to come.

Regular cleaning is one of the most important aspects of maintenance. After each use, it’s crucial to remove any debris, such as grass or dirt, that may have accumulated on the various parts. This helps prevent buildup that could hinder the machine’s performance and affect its cutting precision.

Equally important is checking the alignment and tension of moving parts. Over time, certain components may loosen or shift, which can lead to uneven operation. Regularly inspecting and adjusting these elements ensures smooth functioning and prevents potential damage.

Lastly, always ensure that the lubrication is adequate for all moving components. This reduces friction and wear, contributing to better performance and smoother operation. Consistent oiling and greasing help prevent rust and corrosion, especially in areas exposed to moisture.