When it comes to maintaining heavy-duty farming machinery, understanding its core components is crucial. Proper knowledge of these elements ensures efficient operation and extends the lifespan of the equipment. This section provides an in-depth look at the critical parts that make up these machines and their functions.

With a comprehensive breakdown of each piece, operators can identify potential issues early, perform routine maintenance, and replace worn-out parts effectively. Whether you’re working on a large-scale farm or a smaller operation, understanding these mechanisms is essential for optimal performance and minimal downtime.

Regular inspection of individual components can prevent costly repairs. By familiarizing yourself with how each part interacts within the system, you will improve both your maintenance skills and your overall productivity.

Understanding Key Agricultural Machine Components

In any farming equipment designed for cutting and harvesting, the internal elements work together to ensure smooth operation and high productivity. Each individual component plays a specific role in the overall system, whether it’s for motion, power transfer, or cutting efficiency. Gaining a solid understanding of these parts is crucial for maintaining the machine and addressing any potential issues quickly.

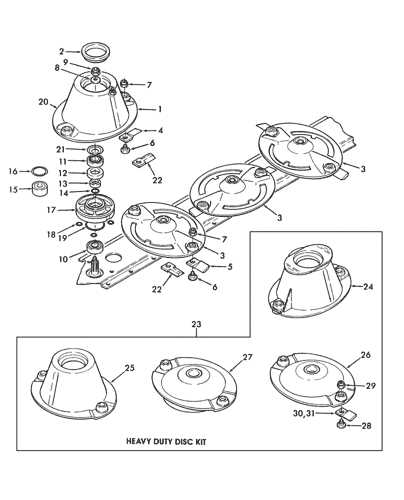

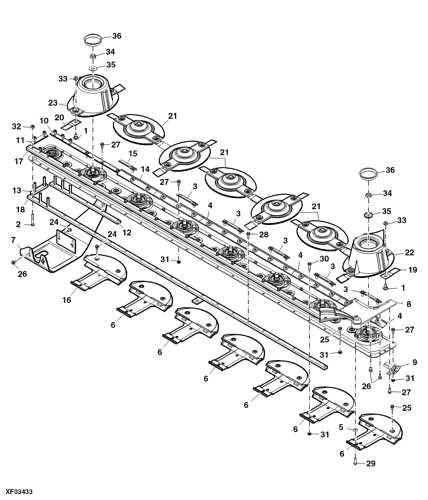

Core Elements of the System

At the heart of the mechanism, several parts contribute to the cutting process and facilitate movement. These include rotating blades, gear systems, and driveshafts, each essential for transferring energy and enabling effective operation. Knowing how these elements interact will help operators troubleshoot and perform regular upkeep to avoid unexpected breakdowns.

Maintenance and Repair Considerations

Regular maintenance of the internal components ensures optimal functionality. Over time, wear and tear can lead to diminished performance. Replacing worn parts, lubricating moving elements, and adjusting tension settings are key to preserving the longevity of the system. Recognizing signs of malfunction in specific areas, such as unusual noises or uneven cuts, can indicate when attention is required.

Common Issues with Agricultural Machine Components

Even the most durable farming equipment can experience malfunctions over time due to wear and tear, environmental factors, and improper maintenance. Identifying and addressing common issues early can save time and money, preventing costly repairs or downtime. This section explores frequent problems encountered in various parts of the machinery and offers tips for troubleshooting.

Worn Blades and Cutting Issues

One of the most common issues faced by operators is blades losing sharpness or becoming damaged after extended use. Dull or chipped blades can result in uneven cuts, leading to poor performance and increased fuel consumption. Regularly inspecting blades for wear and replacing them when necessary will ensure consistent results and minimize strain on the engine.

Drive System Failures

The drive system is responsible for powering the moving parts of the equipment, and failures here can halt operations entirely. A common issue in this area is misalignment or damage to the driveshafts, which can result in excessive vibrations or complete power loss. Ensuring proper alignment and checking for signs of wear can prevent major breakdowns.

How to Maintain Agricultural Machine Components

Regular maintenance is key to extending the lifespan and ensuring the efficiency of any farm equipment. Proper care of individual elements not only improves performance but also helps avoid unexpected repairs. This section outlines essential maintenance tasks that can be done to keep your machinery running smoothly, reduce downtime, and prevent costly breakdowns.

Inspect and Replace Worn Components

One of the most important aspects of upkeep is regularly checking critical elements for signs of wear. Blades, gears, and belts should be inspected frequently for damage, such as cracks or excessive wear. Replacing these parts before they fail can prevent further damage to the system and maintain the overall efficiency of the equipment.

Lubrication and Tension Adjustments

Proper lubrication of moving parts is essential to reduce friction and prevent unnecessary wear. Regularly greasing the necessary components will ensure smoother operation and less strain on the motor. Additionally, adjusting the tension on belts and cables will help maintain the machine’s optimal performance, preventing slippage and excessive vibration during use.