When maintaining outdoor machinery, having a clear understanding of its structure and function is crucial. By familiarizing yourself with the key elements of your device, you can ensure it runs smoothly and performs optimally. A well-detailed map of the device’s setup can simplify repairs and maintenance tasks, making them more efficient and cost-effective.

Accurate identification of each individual component is vital, especially when addressing specific issues. With a comprehensive guide, you will know exactly where each part fits and how to handle its maintenance. This can significantly reduce the likelihood of errors and enhance the longevity of your equipment.

Knowing your machine’s layout empowers you to troubleshoot effectively, minimizing downtime and maximizing productivity. Whether you’re replacing a broken element or performing routine upkeep, a solid grasp of how everything fits together will make the process much more straightforward.

Understanding the Equipment Components

Every machine consists of several essential elements that work together to ensure smooth operation. By grasping the function of each component, you can improve the maintenance process and extend the machine’s lifespan. Knowing how each part interacts helps identify potential issues before they cause significant damage, leading to a more efficient performance.

Key Elements of the Machine’s Structure

At the core of the system are the drive components, which work in unison to provide power to the entire structure. Each section, whether it be a motor or a pulley, plays a vital role in driving the movement necessary for operation. Understanding how these parts contribute to the overall function allows for quicker diagnosis when something goes wrong.

Efficient Troubleshooting and Maintenance

Familiarity with the setup allows you to address problems systematically. By isolating specific components and understanding their individual roles, you can troubleshoot with precision. Regular inspections and a knowledge of the critical components enable you to maintain high efficiency and avoid unnecessary repairs.

How to Use the Components Map Effectively

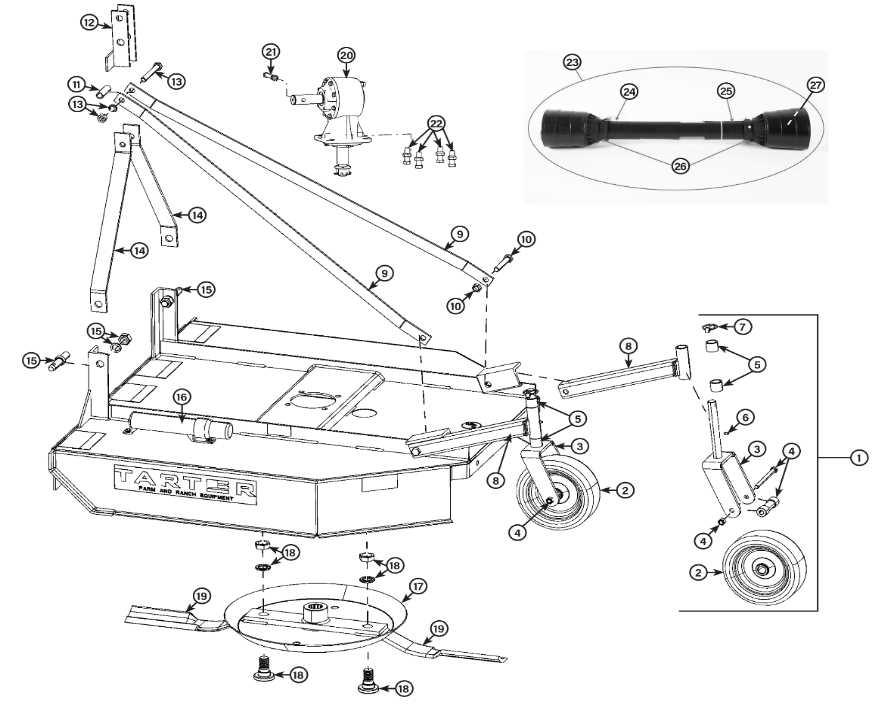

Understanding the layout of your machine is essential for efficient maintenance and repair. A clear visual representation of the system’s structure simplifies the identification of each individual piece, allowing for precise actions when dealing with malfunctions or replacements. When used properly, this guide acts as a valuable reference, streamlining the troubleshooting process.

Step-by-Step Navigation

Start by familiarizing yourself with the overall structure. Focus on major sections first, then drill down into smaller, more intricate components. This method helps break down complex systems into manageable segments, making it easier to locate parts when needed. Understanding the hierarchy will save time and reduce confusion during repairs.

Locating Specific Parts for Replacement

When it’s time to replace a worn-out element, the visual guide becomes a powerful tool. By referencing the exact location and configuration of each component, you can ensure that the replacement is seamless. This eliminates the guesswork and minimizes the risk of errors, ensuring everything fits as intended.

Maintaining Your Equipment with the Map

Regular upkeep is essential to ensure your machine operates at its best. Using a detailed visual guide makes maintenance tasks easier and more effective. It allows you to quickly identify components that require attention, ensuring that you don’t miss any crucial areas during routine checks.

Consistent inspections help in detecting wear and tear early, preventing more significant issues down the line. By referencing the map, you can track which parts have been replaced, and when, giving you a clear history of maintenance activities. This also ensures that you keep your machine running smoothly without unnecessary breakdowns.

Proper lubrication and cleaning of key elements can be done with confidence when you know exactly where everything is located. The guide assists you in finding the correct spots, helping you keep the system running efficiently while reducing the chances of malfunction.