Proper maintenance is key to the longevity and performance of farming machinery. A clear understanding of the various components and their functions can significantly improve operational efficiency and reduce downtime. Regular upkeep ensures that all parts work in harmony, contributing to better results in the field.

When tackling machinery repair or upkeep, it is essential to familiarize oneself with the correct layout and structure of each component. By knowing how each part interacts, you can more easily identify wear and tear, troubleshoot issues, and replace necessary items without confusion.

Clear identification of every element helps to avoid errors during maintenance procedures. This knowledge enhances the effectiveness of farmers and technicians, leading to quicker repairs and more reliable equipment. Whether you’re dealing with basic wear or complex failures, knowing the setup of the machine is crucial to getting it back in working order quickly.

Understanding the New Idea 5407 Mower

Agricultural machines designed for cutting and clearing fields are critical for improving efficiency in farming tasks. These tools rely on well-engineered mechanisms that work together to achieve optimal results, allowing for large-scale operation with minimal manual labor. A clear grasp of how these devices are structured aids in maintenance and troubleshooting.

The equipment is made up of various interconnected components that contribute to its function. Each section plays a vital role in ensuring smooth operation, from the cutting mechanism to the drive system. Understanding how each part contributes to the overall performance can prevent mechanical failures and improve operational longevity.

Regular inspection and maintenance are essential to identify worn-out parts early on. Being able to pinpoint specific sections of the machine allows for targeted repairs, saving time and resources. Knowing how everything fits together ensures that the machine runs smoothly and continues to perform at its best in demanding work environments.

Essential Components of the Mowing Equipment

Every piece of agricultural machinery consists of several key elements that enable it to perform its intended tasks effectively. These components are carefully designed to work in harmony, ensuring optimal performance in cutting and clearing large areas of land. Each part plays a specific role in the overall functionality of the machine, contributing to its efficiency and reliability.

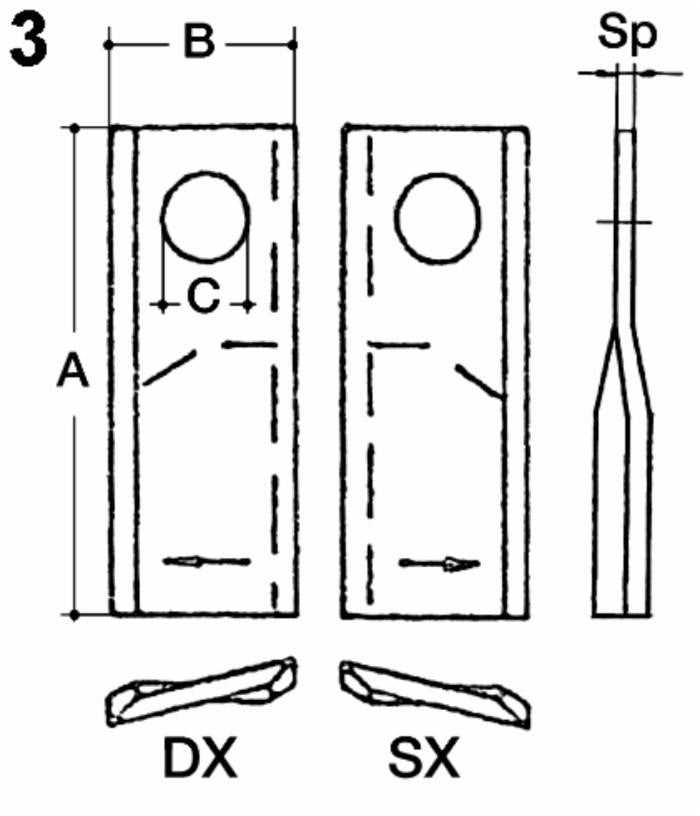

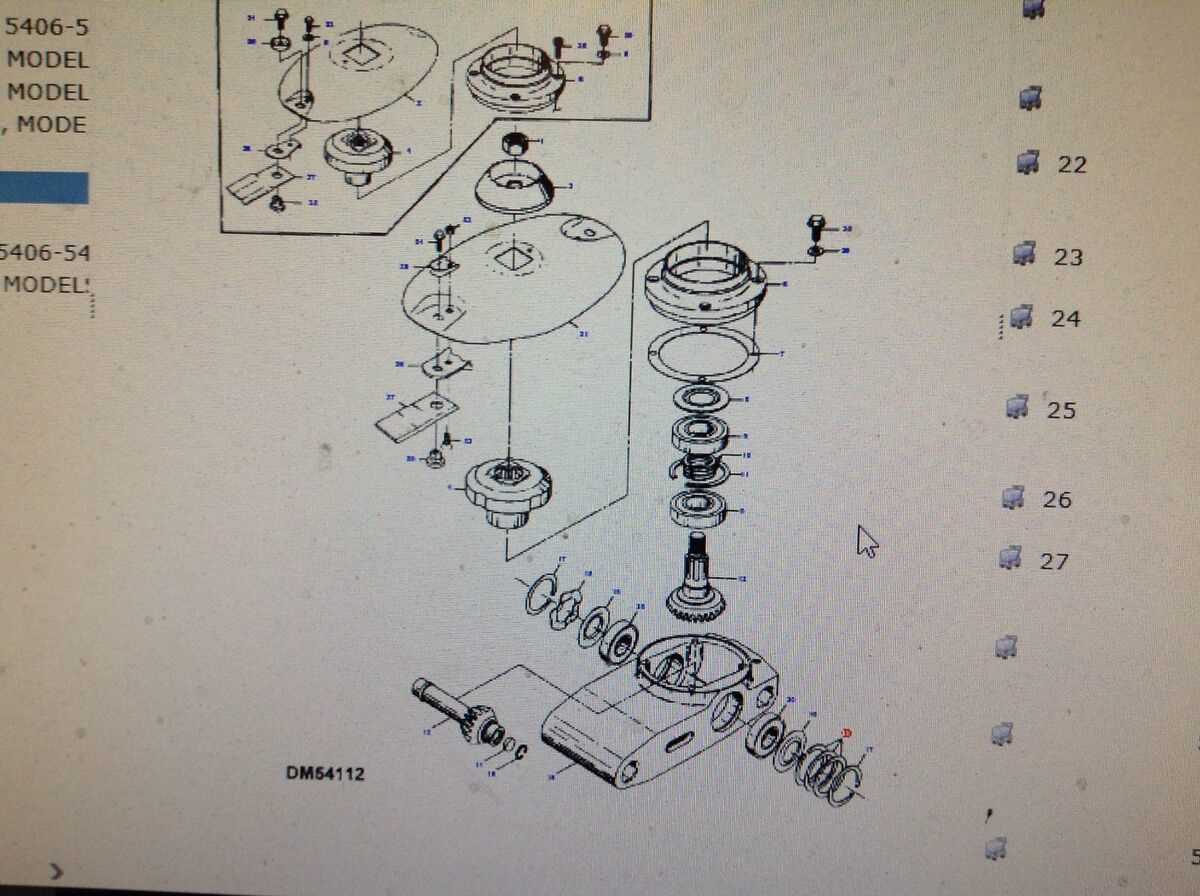

The primary elements of the device include the cutting blades, drive systems, and support frames. The cutting blades are crucial for performing the cutting action, while the drive systems ensure that the blades rotate with sufficient power and speed. Additionally, the frame holds everything in place, providing stability and support during operation. Understanding how these components interact helps to identify potential issues before they affect the machine’s performance.

Regular maintenance of these critical components is necessary to avoid wear and tear that can lead to costly repairs. Proper lubrication, alignment, and inspection of each part ensure that the equipment operates smoothly, extending its lifespan and preventing unexpected breakdowns.

Step-by-Step Guide to Part Replacement

Replacing components in agricultural machinery requires careful attention and proper techniques to ensure that each element functions as intended. The process can be straightforward if approached with a clear understanding of the necessary steps and the tools required. Following a step-by-step guide minimizes the risk of errors and ensures that the machine is restored to its optimal condition.

Preparation and Safety Measures

Before starting any repair, make sure the equipment is turned off and disconnected from its power source. Gather all the necessary tools and replacement components to avoid interruptions during the process. It is also important to have a clean workspace to keep everything organized and to ensure the safety of both the operator and the equipment.

Replacing the Worn Components

Begin by removing any damaged parts, carefully following the manufacturer’s instructions for disassembly. Make sure to inspect each component thoroughly for signs of further wear. Once the damaged parts are removed, install the new components, ensuring they are properly aligned and secured in place. Tighten all bolts and fasteners to prevent any loose connections during operation.

After replacing the components, perform a thorough check to confirm everything is functioning correctly. Test the equipment in a controlled environment before returning it to full operation to ensure it is ready for use without any issues.