Proper maintenance of agricultural machinery is crucial for its longevity and optimal performance. Understanding the various components that make up these machines helps ensure they run smoothly and efficiently. Recognizing when and how to replace worn-out or damaged elements can prevent costly repairs and downtime, ultimately saving time and money for farm operators.

In this article, we will provide a detailed overview of the structure and individual elements of a specific model of farm machinery. By breaking down its components and their functions, users will gain the necessary knowledge to perform routine inspections and maintenance. This will help ensure that every part of the machine operates as intended, maintaining high productivity levels throughout the season.

Knowing the function of each key part is the first step toward effective upkeep. From cutting systems to mechanical connections, understanding the role of each element allows for better identification of issues before they escalate. Regular checks and informed decisions about repairs contribute to the overall efficiency and reliability of the equipment in the long run.

Understanding New Idea 5408 Mower Design

A comprehensive understanding of farm machinery design is essential for anyone working with large-scale equipment. Each piece of machinery is a complex system where different elements function together to achieve maximum efficiency. By analyzing the overall structure, operators can ensure they maintain the machine properly and spot potential issues early on. The layout and configuration of the various systems are key to understanding how each part contributes to the performance and reliability of the equipment.

Key Features of the Equipment Structure

The machine’s design incorporates several critical features that enable it to perform efficiently under tough conditions. These include its cutting mechanisms, frame design, and drive systems. Each feature is integrated in a way that allows the equipment to operate at high capacity while maintaining durability. Recognizing how these elements interact with one another is crucial for both routine maintenance and troubleshooting. Proper attention to each aspect of the system ensures optimal results throughout the machinery’s lifespan.

How the Design Influences Performance

The configuration and materials used in the construction of the machine directly impact its performance in the field. A well-designed system will reduce wear and tear on components, improve cutting efficiency, and lower fuel consumption. Understanding the design also allows operators to optimize usage by making small adjustments that can have a significant effect on the overall operation. Proper maintenance based on the design layout keeps the machinery working efficiently and reduces the risk of costly repairs.

Essential Parts for Effective Maintenance

For any large agricultural machine, regular upkeep relies heavily on understanding and maintaining its critical components. These essential elements play a significant role in ensuring the equipment runs smoothly and efficiently, minimizing downtime and preventing costly repairs. Keeping track of these parts and their condition helps operators recognize issues before they affect overall performance. Proper maintenance ensures that each component functions optimally, contributing to the machinery’s overall durability and reliability.

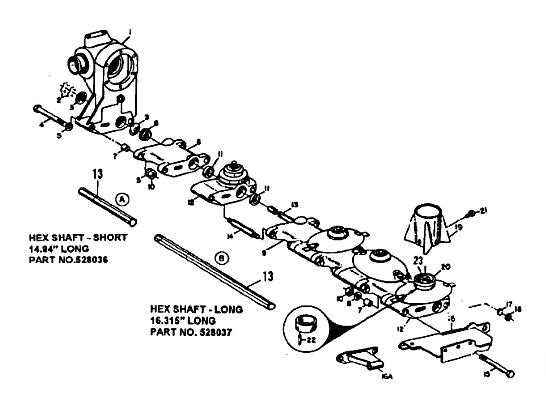

Among the key components that need frequent attention are the cutting systems, drive mechanisms, and the structural framework. Each of these parts works in tandem to ensure the machine operates efficiently, with minimal wear. Routine checks and the replacement of worn-out elements within these systems are crucial for maintaining peak performance and extending the equipment’s service life. Understanding the importance of each of these elements allows operators to focus on the areas that require the most attention during inspections and servicing.

How to Identify and Replace Damaged Components

Identifying and replacing damaged elements within farm machinery is a critical aspect of maintaining performance and preventing further damage. Regular inspections are key to spotting issues early, whether from wear and tear or other operational factors. Understanding how to properly assess and replace these parts ensures the machine runs at its best, reducing the risk of major breakdowns. Timely replacements and repairs not only extend the life of the equipment but also optimize its efficiency during operation.

Steps to Identify Malfunctioning Components

The first step in detecting damage is to conduct thorough visual and operational checks. Inspecting components such as drive belts, cutting mechanisms, and structural connections can reveal signs of wear, cracks, or misalignment. Listen for unusual noises and watch for irregular vibrations during use. These indicators can often point to specific parts that need attention. Additionally, checking for loose bolts or signs of corrosion is essential for detecting hidden issues that may not be immediately visible.

Replacing Damaged Elements

Once a damaged component is identified, the next step is ensuring its proper replacement. Begin by obtaining the correct replacement part that matches the machine’s specifications. After removing the damaged part, carefully install the new one, ensuring it is securely fitted. Follow manufacturer guidelines for the proper torque settings and maintenance intervals to ensure longevity. Regularly replacing these elements, when needed, will help maintain the machinery’s optimal functionality and prevent costly repairs in the future.