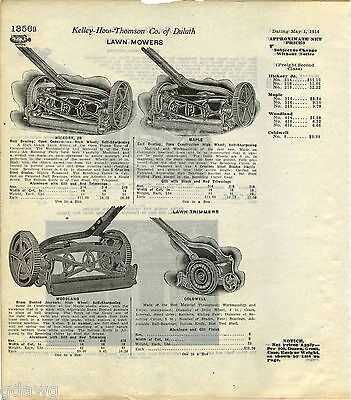

Maintaining your lawn care equipment in top condition requires a solid understanding of its individual components. Whether you’re dealing with a traditional model or a modern variant, knowing how each part functions will ensure smooth operation and effective performance. In this guide, we will explore the essential elements of these tools and their interconnections.

Each machine consists of several critical parts that work together to achieve optimal results. From the blades that cut the grass to the mechanisms that drive motion, understanding the role of each element can make troubleshooting and repairs much easier. Proper knowledge can also help you extend the life of your equipment and avoid costly replacements.

Familiarity with these components can also lead to more informed decisions when it comes to purchasing replacement items or choosing the right maintenance routines. By examining how these pieces interact, you can gain a deeper appreciation of your equipment’s design and functionality.

Understanding Lawn Equipment Components

To ensure proper functioning and longevity of your lawn care tools, it’s crucial to understand how each individual element contributes to the overall performance. These tools are made up of various components that work in harmony to achieve a smooth and precise cut. By recognizing the role of each part, you can identify potential issues and make informed decisions regarding maintenance and repairs.

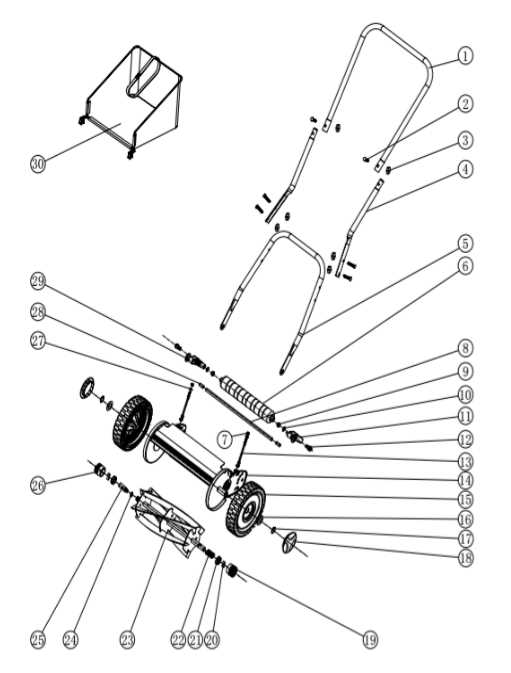

At the heart of the machine, the cutting mechanism is key to achieving a clean and even trim. It consists of rotating blades that slice through the grass, and the way they are aligned and sharpened directly impacts the quality of the result. Surrounding this system are several auxiliary components that help drive motion, ensure stability, and protect the internal elements from wear and tear.

Understanding how these components interact allows for a deeper appreciation of their design. For example, the connection between the drive system and the cutting mechanism ensures seamless operation, while the frame and wheels provide support and maneuverability. Regular inspection and maintenance of these key elements are essential for keeping the equipment running efficiently.

How to Identify Lawn Equipment Components

Recognizing the individual components of your lawn care equipment is the first step in proper maintenance and troubleshooting. Knowing how to identify each part can help you pinpoint issues quickly and avoid unnecessary repairs. It’s important to familiarize yourself with the key elements so you can take better care of your tools and ensure they remain in good working order.

Inspecting the Cutting Mechanism

The cutting system is central to the performance of your tool. Look for the rotating blades that interact with the grass. These blades should be sharp, properly aligned, and free from any debris that might obstruct their movement. Check for:

- Sharpness and wear on the cutting edges

- Alignment of the blades and any signs of uneven cutting

- Debris buildup that could impair operation

Examining the Drive System

The drive system provides the power needed to move the blades and allow the equipment to function smoothly. Identifying issues here can help you restore proper movement. Focus on the following areas:

- Condition of the wheels and any signs of wobbling or damage

- Inspecting the gears for wear or misalignment

- Checking the belt or drive mechanism for tightness and proper function

Common Issues with Lawn Equipment Components

Like any mechanical tool, lawn care devices can encounter a range of issues over time. Understanding the most common problems can help you diagnose and fix them quickly, ensuring your equipment continues to perform efficiently. From dull blades to worn-out drive systems, these common issues often arise due to regular use or lack of maintenance.

One of the most frequent problems involves the cutting mechanism. Over time, blades can become dull or misaligned, resulting in uneven cuts and increased strain on the motor. Similarly, the drive system can develop issues such as slipping belts or worn gears, which can lead to reduced movement and efficiency. These issues often stem from regular wear or insufficient lubrication.

Other common problems include:

- Debris buildup around the cutting blades, affecting performance

- Worn wheels or frames, causing difficulty in maneuvering the device

- Loose or damaged components in the internal mechanism, leading to irregular operation

Proper maintenance, such as regular cleaning, blade sharpening, and lubrication, can help prevent these problems and extend the lifespan of your equipment.